Salt rock base mixture, preparation method and application

A technology of mixed material and salt rock, which is applied to roads, on-site paved concrete pavements, buildings, etc., can solve problems such as poor stability of salt rock roadbeds, save transportation costs, avoid interlayer slippage, and alleviate structural damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The present embodiment provides a kind of salt rock base compound, in parts by weight, is made of the following raw materials: salt rock aggregate is 75 parts, saturated brine is 7 parts, polyvinyl alcohol is 2 parts, calcium carbonate micropowder is 1.5 parts, 2 parts of aluminate coupling agent, 7 parts of emulsion, 0.5 parts of lignin fiber, 1.5 parts of slaked lime, 1 part of alkali slag, 1 part of furnace ash, and 1.5 parts of slag powder.

[0060] Wherein the emulsion is made of the following raw materials in parts by weight: 60 parts of hydroxyl polyacrylate, 30 parts of polyurethane and 10 parts of methacrylate.

[0061] The preparation method of the rock salt base mixture of the present embodiment may further comprise the steps:

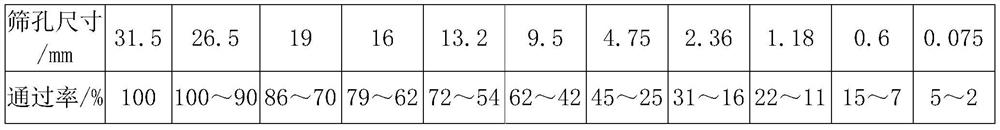

[0062] Step 1, according to the target gradation of sieve size 4.75mm in Table 1, the salt rock aggregate is divided into two parts, one is coarse grain salt rock aggregate, and the other is fine grain salt rock aggregate;

[0063] S...

Embodiment 2

[0091] The present embodiment provides a kind of salt rock base compound, in parts by weight, is made of the following raw materials: salt rock aggregate is 73 parts, saturated brine is 6 parts, polyvinyl alcohol is 3 parts, calcium carbonate micropowder is 1 part, 3 parts of aluminate coupling agent, 8 parts of emulsion, 1 part of lignin fiber, 1 part of slaked lime, 0.5 part of alkali slag, 1.5 parts of furnace ash, and 2 parts of slag fine powder.

[0092] In this embodiment, the emulsion in the rock salt base compound formulation is the same as that in Embodiment 1.

[0093] In this embodiment, the preparation method of the salt rock base layer mixture is basically the same as that in Embodiment 1.

[0094] The salt rock base mixture of this embodiment is used for the application of building a gravel seal layer salt rock base. In the present embodiment, the specific method for the application of the rock-salt base mixture is basically the same as that of Example 1, the di...

Embodiment 3

[0098] The present embodiment provides a kind of salt rock base compound, in parts by weight, made of the following raw materials: 77 parts of salt rock aggregate, 8 parts of saturated brine, 1 part of polyvinyl alcohol, and 1 part of calcium carbonate micropowder. 2 parts, 1 part of aluminate coupling agent, 6 parts of emulsion, 0.5 parts of lignin fiber, 2 parts of slaked lime, 1.5 parts of alkali slag, 0.5 part of furnace ash, and 1 part of slag powder.

[0099] In this embodiment, the emulsion in the rock salt base compound formulation is the same as that in Embodiment 1.

[0100] In this embodiment, the preparation method of the salt rock base layer mixture is basically the same as that in Embodiment 1.

[0101] The salt rock base mixture of this embodiment is used for the application of building a gravel seal layer salt rock base. In the present embodiment, the specific method for the application of the rock-salt base mixture is basically the same as that of Example 1, ...

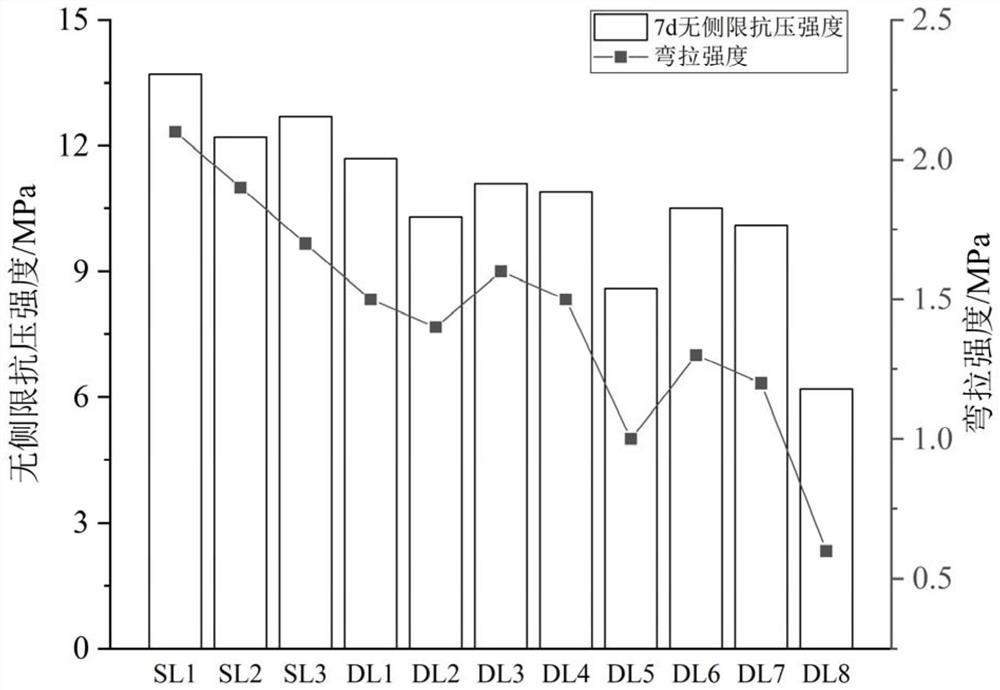

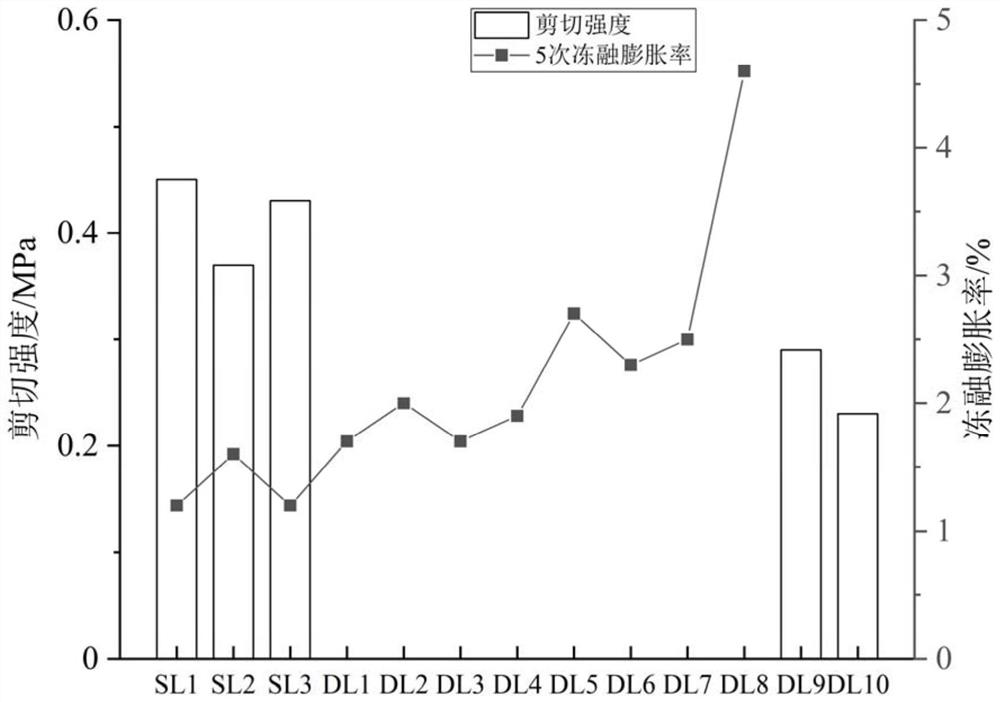

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap