Double-branched-chain organosilicon quaternary ammonium salt as well as preparation method and application thereof

A technology of organosilicon quaternary ammonium salt and double branched chain, which is applied in the fields of botanical equipment and methods, applications, organic chemistry, etc., can solve the problems of skin and mucous membrane irritation, high equipment requirements, low output, etc., to reduce High risk and high energy consumption, easy industrial scale-up production, solve the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

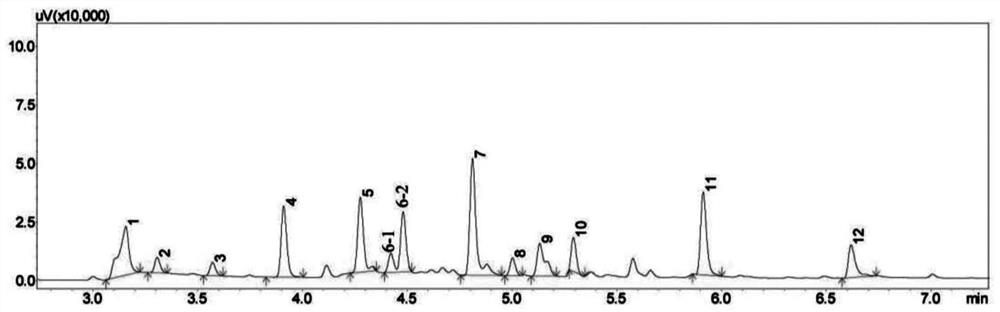

Examples

preparation example Construction

[0055] Another aspect of the present invention provides a method for preparing a double-branched organosilicon quaternary ammonium salt. In an exemplary embodiment of the preparation method of the double-branched organosilicon quaternary ammonium salt of the present invention, the following steps may be included:

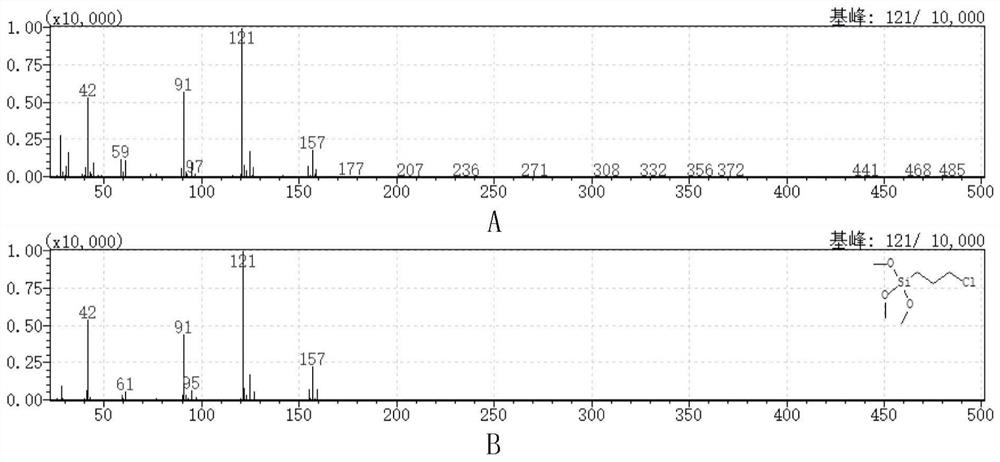

[0056] Step 01, mix N-methyldiethanolamine with the structure of formula I and 3-chloropropyltriethoxysilane with the structure of formula II and place it in a reactor, add the first solvent and catalyst, and heat under an inert atmosphere To the end of the reaction, remove the first solvent, remove the lower layer of liquid after layering, and obtain a colorless transparent liquid-quaternary ammonium salt intermediate with the structure of formula III after washing. The reaction process is as follows:

[0057]

[0058] Step 02, mix the quaternary ammonium salt intermediate with the structure of formula III with the acid chloride, add the second solvent, heat unt...

example 1

[0080] Step 1, N-methyldiethanolamine and 3-chloropropyltriethoxysilane are mixed in a molar ratio of 1:1.2 and then added to the reaction vessel, 30%wt of isopropanol is added as a solvent, and KI is used as a catalyst ( KI and N-methyldiethanolamine molar ratio 0.01:1), in N 2 Under protection, heat to 110°C and reflux for 16 hours. After completion, vaporize to remove the isopropanol solvent. After layering, take the lower layer liquid and wash with a small amount of ethyl acetate to obtain a colorless transparent liquid, which is the quaternary ammonium salt intermediate;

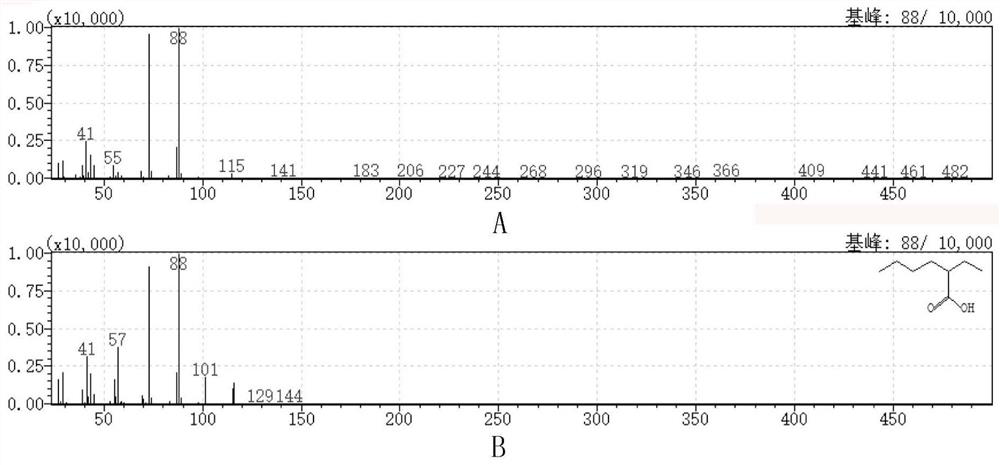

[0081] Step 2, mix the quaternary ammonium salt intermediate obtained in step 1 with 2-ethylhexanoyl chloride at a molar ratio of 1:3, add it to the reaction vessel, add acetonitrile solvent, heat to 100°C for reflux reaction for 12 hours, and then vaporize and remove the acetonitrile Solvent, let it stand to be separated, wash with a small amount of ethyl acetate, and remove the lower layer of transpar...

example 2

[0088] Step 1, N-methyldiethanolamine and 3-chloropropyltriethoxysilane are mixed in a molar ratio of 1:1.5 and added to the reaction vessel, 30wt% isopropanol is added as a solvent, and KI is used as a catalyst (KI and N -Methyldiethanolamine mol ratio 0.01:1) and add reaction system gross mass 0.02%wt BHT antioxidant, in N 2 Under protection, heat to 100°C and reflux for 20 hours. After completion, vaporize to remove the solvent. After layering, take the lower layer liquid and wash with a small amount of ethyl acetate to obtain a colorless transparent liquid, which is the quaternary ammonium salt intermediate;

[0089] Mix the above-mentioned quaternary ammonium salt intermediate with 2,2-dimethylbutyryl chloride in a molar ratio of 1:3 and add it into the reaction vessel, add acetonitrile solvent, heat up to 100°C for reflux reaction for 12 hours, evaporate the solvent after completion, and let it stand for The layers were separated, washed with a small amount of ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com