A kind of decolorizing resin for lactase and preparation method thereof

A decolorizing resin and lactase technology, applied in biochemical equipment and methods, glycosylases, enzymes, etc., can solve the problems of low efficiency of lactase decolorization treatment, large loss of enzyme activity, poor decolorization effect, etc., to protect lactose Enzyme activity, reduced dosage, enhanced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

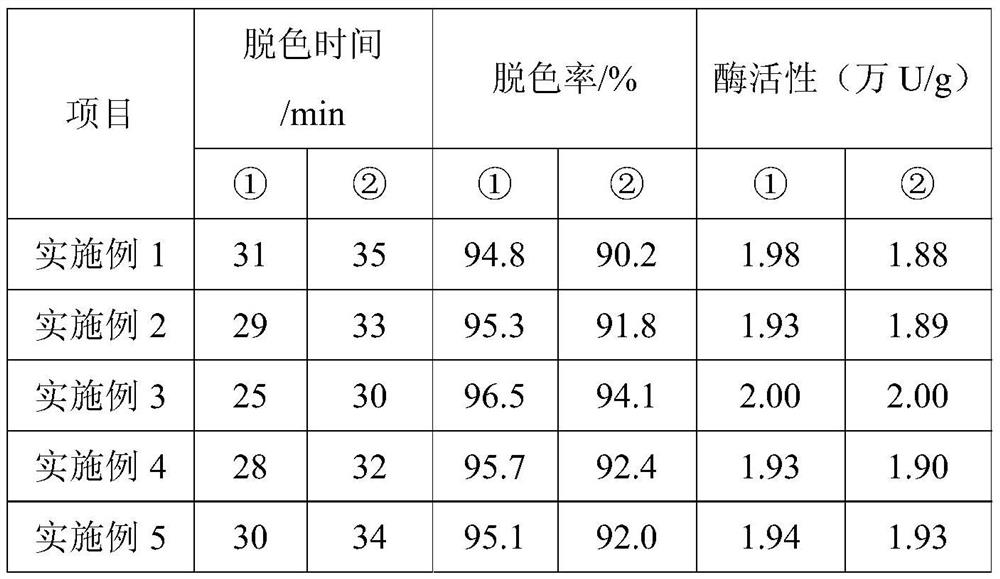

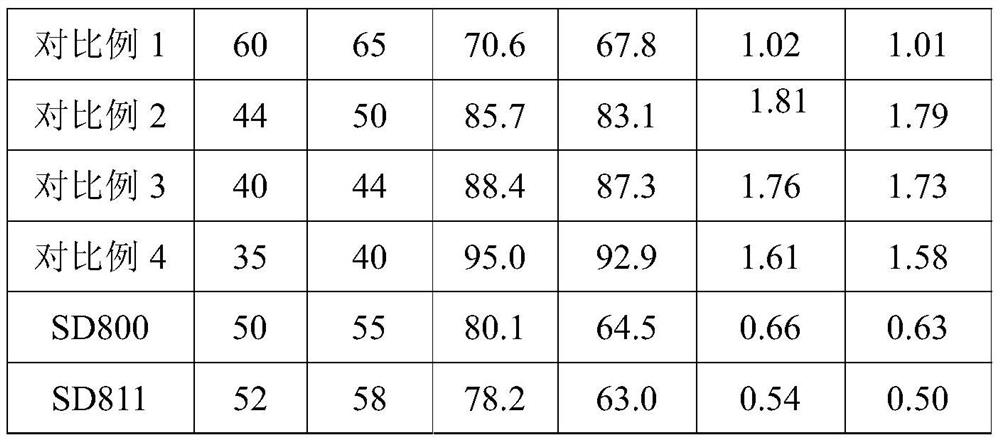

Examples

Embodiment 1

[0028] A decolorizing resin for lactase prepared from raw materials comprising the following weights:

[0029] 5 parts of styrene, 80 parts of divinylbenzene, 20 parts of gelatin, 1 part of rush, 10 parts of methyl isobutyl methanol, 20 parts of hydroxyethyl methacrylate, 1 part of triallyl cyanurate, N -1 part of phenylmaleimide, 3 parts of chitosan, 1 part of magnesium vitamin C phosphate, 1.8 parts of benzoyl peroxide, 1 part of polyvinyl alcohol, 0.03 part of tributyl phosphate, 0.03 part of salicylic acid parts, 2 parts of hydroxyethyl methyl cellulose, and 5 parts of toluene.

[0030] The preparation method of the decolorizing resin for lactase, comprising the following steps:

[0031] A: Dissolve gelatin and hydroxyethyl methyl cellulose in water according to a material-to-liquid ratio of 1:2, heat to 50°C, then add chitosan, polyvinyl alcohol, and salicylic acid, and heat for 5 minutes to prepare a liquid phase ;

[0032] B: Styrene, divinylbenzene, methyl isobutyl ...

Embodiment 2

[0036] A decolorizing resin for lactase, prepared from raw materials comprising the following weights: 3 parts of styrene, 60 parts of divinylbenzene, 50 parts of gelatin, 2 parts of rushes, 12 parts of methyl isobutyl methanol, 30 parts hydroxyethyl acrylate, 2 parts triallyl cyanurate, 2 parts N-phenylmaleimide, 5 parts chitosan, 2 parts magnesium vitamin C phosphate, benzoyl peroxide 1.2 parts, 1.2 parts of polyvinyl alcohol, 0.02 parts of tributyl phosphate, 0.02 parts of salicylic acid, 1 part of hydroxyethyl methyl cellulose, and 10 parts of xylene.

[0037] The preparation method of the decolorizing resin for lactase, comprising the following steps:

[0038] A: Dissolve gelatin and hydroxyethyl methyl cellulose in water according to a material-to-liquid ratio of 1:3, heat to 58°C, then add chitosan, polyvinyl alcohol, and salicylic acid, and heat for 15 minutes to prepare a liquid phase ;

[0039] B: Styrene, divinylbenzene, methyl isobutyl methanol, hydroxyethyl meth...

Embodiment 3

[0043] A decolorizing resin for lactase, prepared from raw materials comprising the following weights: 7 parts of styrene, 65 parts of divinylbenzene, 35 parts of gelatin, 10 parts of rushes, 20 parts of methyl isobutyl methanol, 35 parts of hydroxyethyl acrylate, 3 parts of triallyl cyanurate, 3 parts of N-phenylmaleimide, 7 parts of chitosan, 4 parts of vitamin C magnesium phosphate, benzoyl peroxide 1.5 parts, polyvinyl alcohol 1.5 parts, tributyl phosphate 0.01 parts, salicylic acid 0.05 parts, hydroxyethyl methyl cellulose 1.2 parts, toluene 10 parts, xylene 10 parts.

[0044] The preparation method of the decolorizing resin for lactase, comprising the following steps:

[0045] A: Dissolve gelatin and hydroxyethyl methyl cellulose in water according to the ratio of material to liquid of 1:4, heat to 60°C, then add chitosan, polyvinyl alcohol, and salicylic acid, and keep reacting for 12 minutes to prepare a liquid phase ;

[0046] B: Styrene, divinylbenzene, methyl isob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com