MEMS silicon-based cavity circulator/isolator circuit film structure and preparation method

A circulator and isolator technology, applied in the field of MEMS silicon-based cavity circulator/isolator circuit film layer structure and preparation, can solve the problems of reducing the resistivity of high-resistance silicon, increasing device insertion loss, and large conductor loss, etc. , to achieve the effect of reducing insertion loss, reducing conductor loss and low loss requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

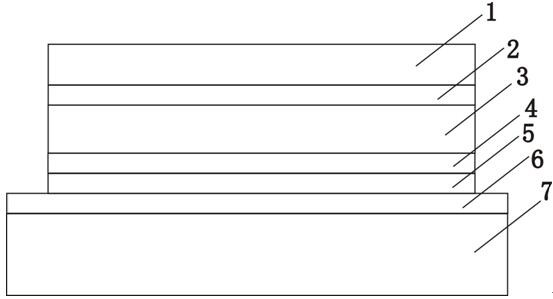

[0034] see figure 1 , a MEMS silicon-based cavity circulator / isolator circuit film structure, which includes a gold film layer 1, a barrier film layer 2 (titanium film), a copper film layer 3, and a tantalum nitride support film layer 4 from top to bottom , base film layer 5 (chromium film), isolation film layer 6 (silicon dioxide film) and high resistance silicon layer 7;

[0035] The preparation method is as follows:

[0036] (1) Marking and cleaning two high-resistance silicon layers 7;

[0037] (2) Uniformly oxidize a layer of 300nm thick silicon dioxide film on the front and back of the high resistance silicon layer 7 as the isolation film layer 6;

[0038] (3) Magnetron sputtering is used to sputter a layer of metal chromium thin film as the base layer 5, room temperature sputtering, sputtering power 180W, chromium film thickness 30nm;

[0039] (4) Put the silicon wafer into a box furnace for vacuum annealing, the annealing temperature is 250°C, and the annealing time...

Embodiment 2

[0049] A MEMS silicon-based cavity circulator / isolator circuit film structure, which includes gold film layer 1, barrier film layer 2 (titanium film), copper film layer 3, tantalum nitride support film layer 4, Primer film layer 5 (titanium film), isolation film layer 6 (silicon dioxide film) and high resistance silicon layer 7;

[0050] The preparation method is as follows:

[0051] (1) Marking and cleaning two high-resistance silicon layers 7;

[0052] (2) Uniformly oxidize a layer of 180nm thick silicon dioxide film on the front and back of the high-resistance silicon layer 7;

[0053] (3) Magnetron sputtering is used to sputter a layer of metal titanium thin film as the base layer 5, room temperature sputtering, sputtering power 180W, titanium film thickness 50nm;

[0054] (4) Sputter a layer of copper film on the titanium film, the sputtering temperature is 400°C, the sputtering power is 900W, and the thickness of the copper film is 4000nm;

[0055] (5) sputtering a la...

Embodiment 3

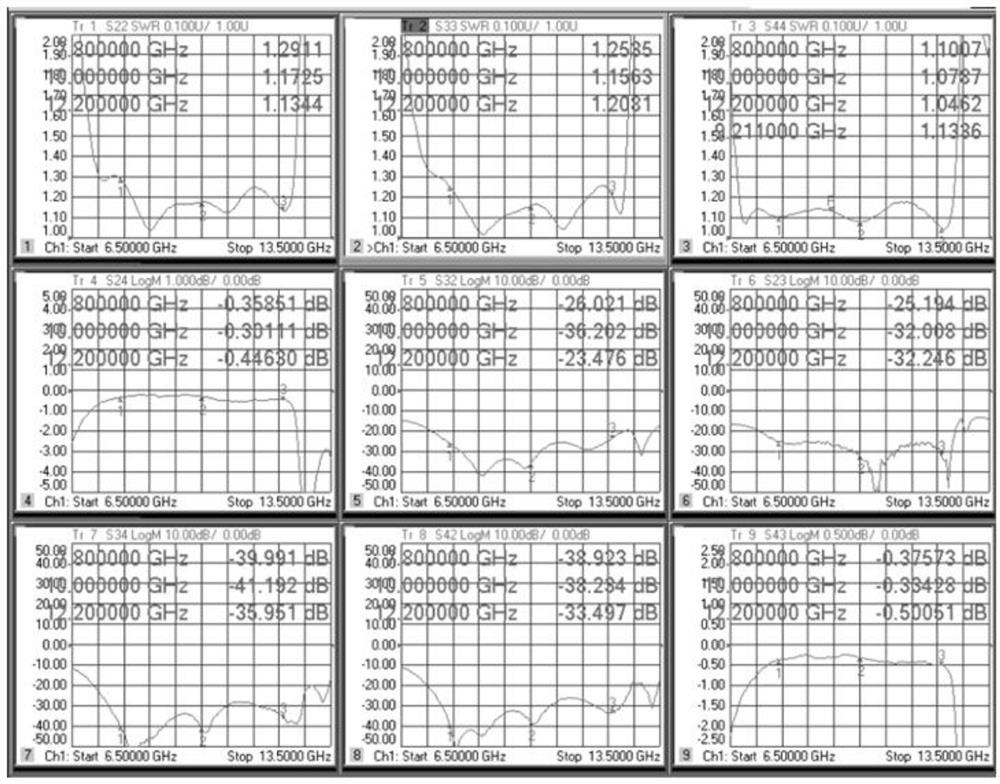

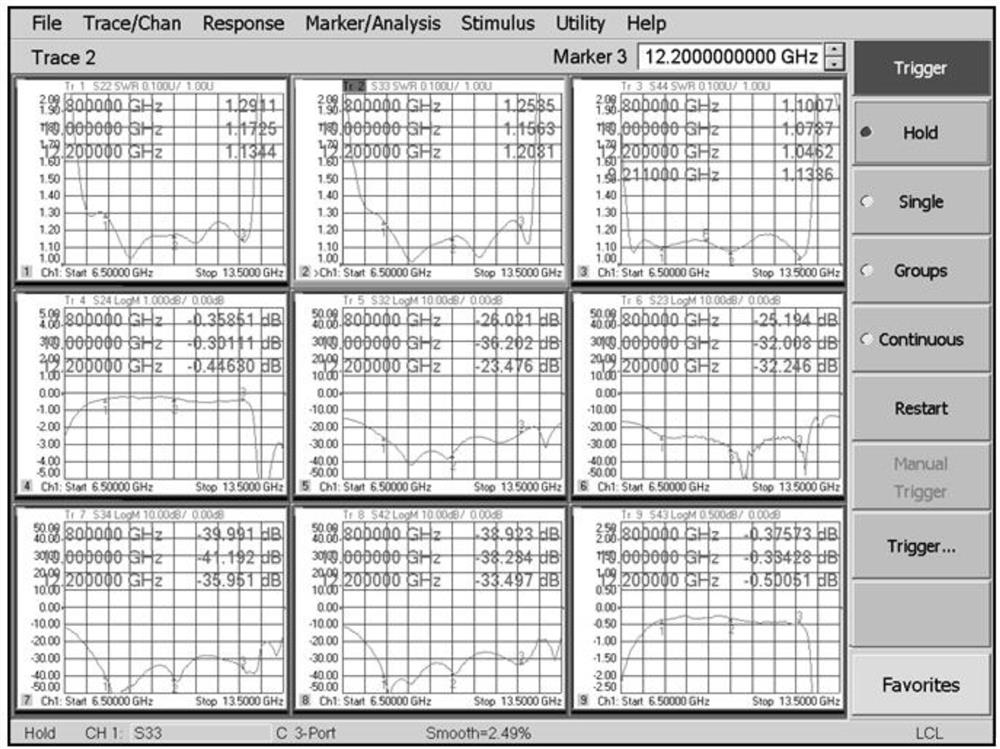

[0062] Compared with Example 2 in this example, only in step (2) is "a metal titanium layer after uniformly evaporating a layer of 50nm metal titanium layer on the front and back of the high-resistance silicon layer 7, and the rest are the same as in Example 1, using the obtained film layer structure, the electrical performance test was carried out on the assembled 8-12GHz MEMS silicon-based isolator device, and the result was that the insertion loss ILMAX=0.58dB of the single-section device was 0.17dB lower than that of the MEMS isolator with the chromium / gold structure in the same frequency band.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com