Photoelectric synergistic capacitive deionization electrode material and preparation method and application thereof

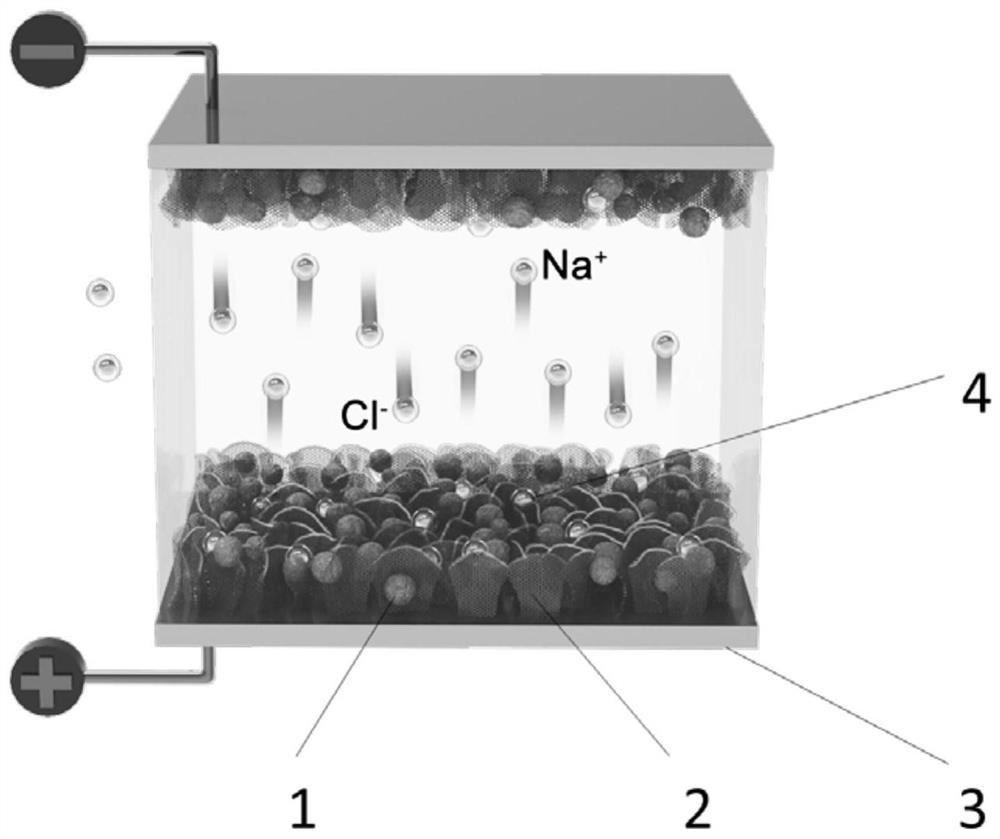

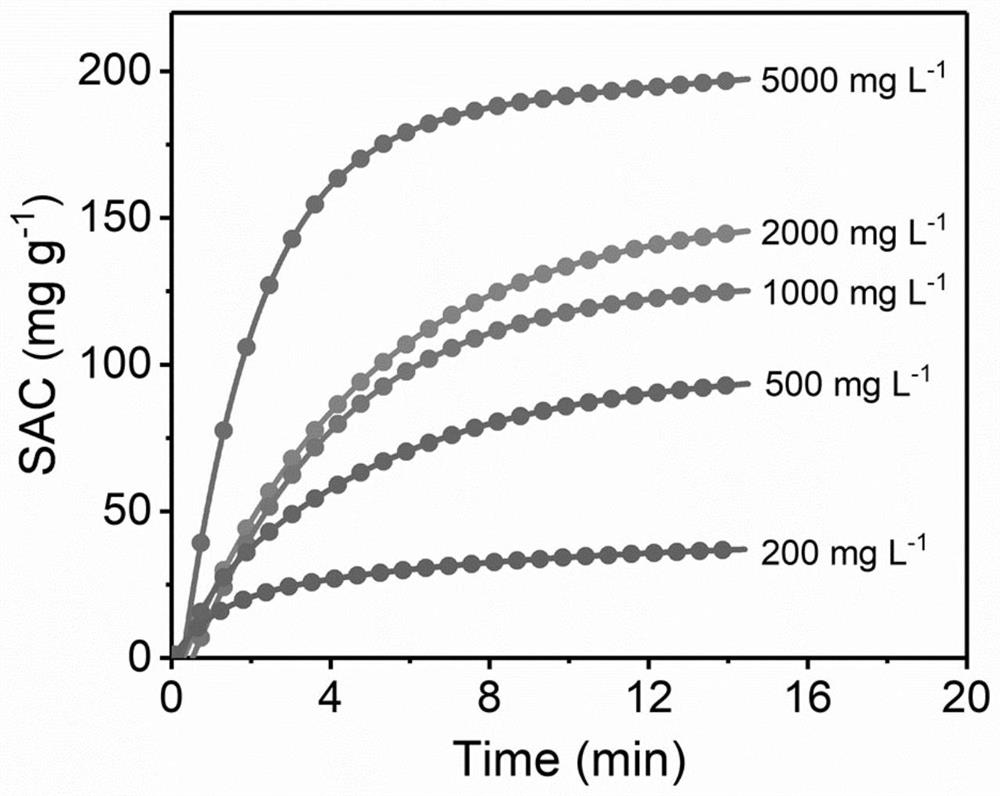

A technology for capacitive deionization and electrode materials, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of semiconductor catalysts lacking surface porous structure, unable to provide adsorption surface for electrolyte ions, and limiting the specific capacitance of electrode materials. , to achieve the effect of promoting electrostatic adsorption of ions, simple and stable preparation method, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

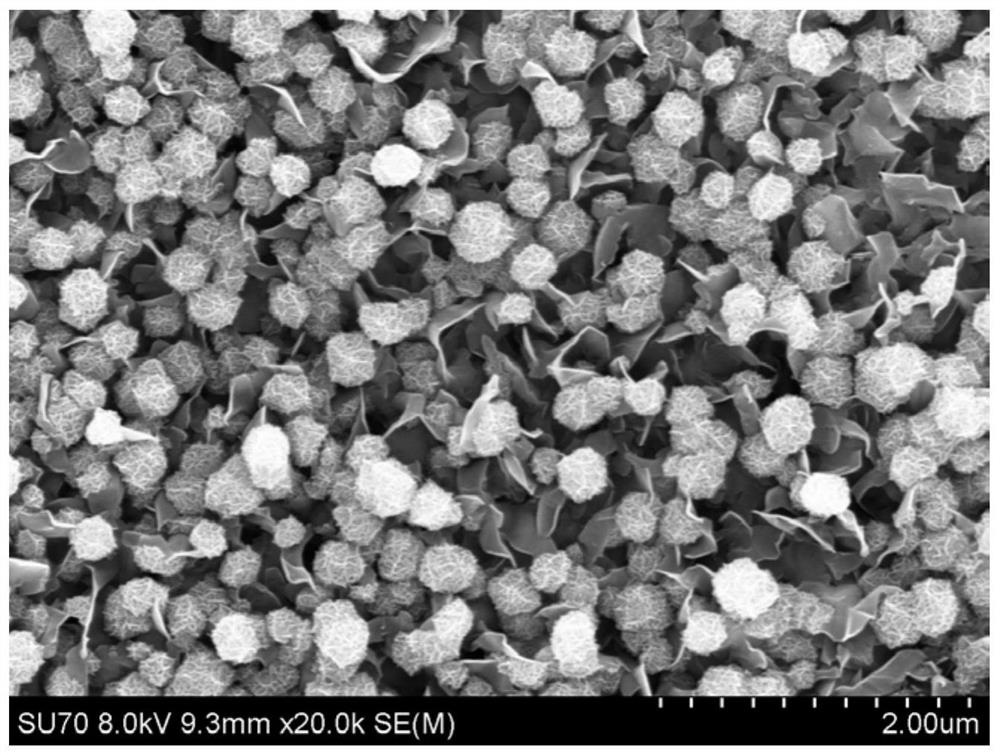

[0042] The preparation method of photoelectric synergistic capacitive deionization electrode material includes the following steps: placing a conductive substrate in a plasma-enhanced chemical vapor deposition tube, feeding a mixed gas of hydrogen and methane, the gas flow ratio is 10:1, the air pressure is 40Pa, and the inductor is turned on. Coupled plasma source, the power is set to 250W. After the chemical vapor deposition reaction was carried out at 700°C for 60 minutes, 10mL / min nitrogen gas was passed into it for cooling. The height of the standing graphene nanosheets on the conductive substrate was about 1 μm, the length of the single sheet was about 400nm, and the thickness of the top edge was 3nm. The load density is about 0.15mg / cm 2 ; The obtained standing graphene nanosheet / conductive substrate is placed in the plasma ozone generator, the ozone concentration is 200ppm, and it is maintained for 3min; using cyclic voltammetry, the sweep rate is set to 20mV / s, and th...

Embodiment 2

[0053] The difference from Example 1 is that the chemical vapor deposition reaction time is 10min, the height of the obtained standing graphene nanosheets on the conductive substrate is about 0.5 μm, the length of the single piece is about 300nm, the thickness of the top edge is 2nm, and the loading density About 0.1mg / cm 2 .

Embodiment 3

[0055] Different from Example 1, the chemical vapor deposition reaction time is 180min, and the height of the obtained standing graphene nanosheet on the conductive substrate is about 2 μm, the length of the single piece is about 800nm, the thickness of the top edge is 5nm, and the loading density is about 2 μm. 0.30mg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com