Additive for airfield pavement machine-made sand dry hard concrete

A concrete water reducing agent and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of natural sand fineness modulus, difficulty loss of consistency, strong edges and corners, etc., to achieve Good anti-mud and plastic-retaining effect, guarantee the depth of roughening groove, and improve the strength of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

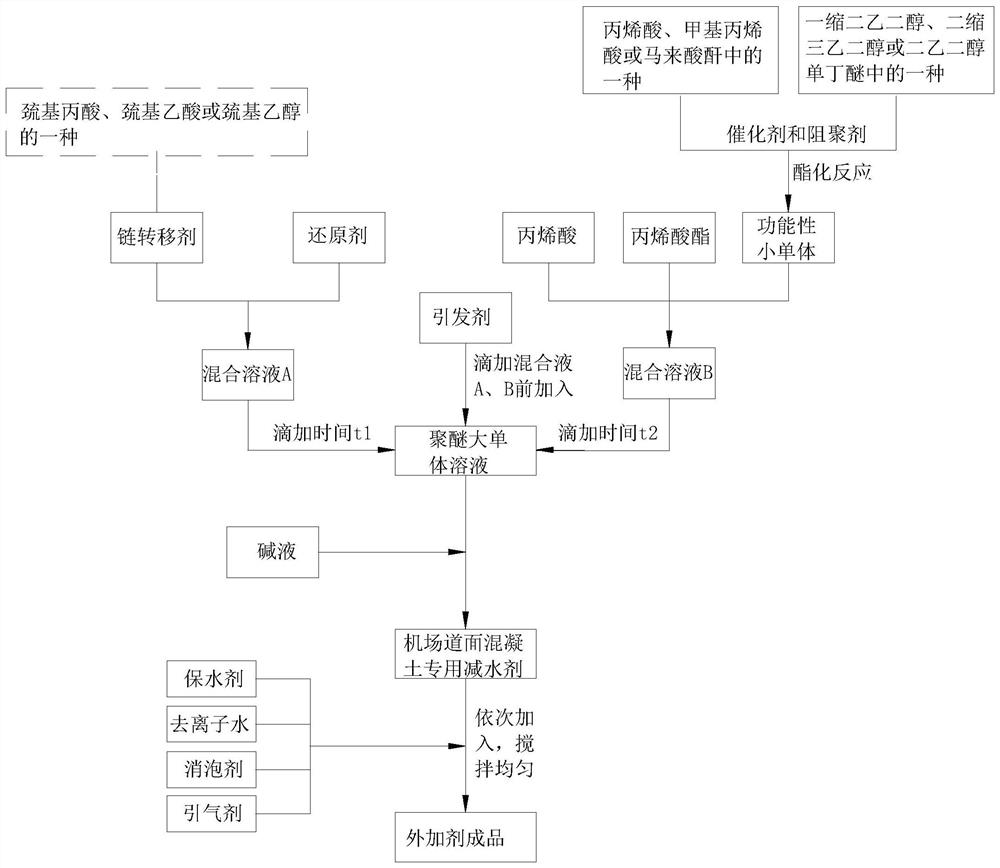

[0038] combine figure 1 , an admixture for machine-made sand dry hard concrete on airport pavement, is characterized in that it includes machine-made sand airport pavement concrete water reducer, water retaining agent, defoamer, air-entraining agent and water, and the weight of each component The serving content is:

[0039]

[0040] Machine-made sand airport pavement concrete superplasticizer is polycarboxylate high-performance superplasticizer with a solid content of 40%-45% and a water-reducing rate of 20%-25%;

[0041] The water retaining agent is composed of the following raw materials in parts by weight: 48-52 parts of hydroxypropyl methylcellulose ether, 18-22 parts of bentonite, 9-11 parts of diatomite, 9-11 parts of polyvinyl alcohol and 9-10 parts of polyacrylamide 11 parts, all raw materials are stirred and mixed evenly.

[0042] The defoaming agent is a polyether defoaming agent or a silicone defoaming agent. The defoaming agent is used to eliminate large air ...

Embodiment 2

[0058] An airport pavement machine-made sand dry hard concrete, including the above-mentioned admixture for the airport pavement machine-made sand dry hard concrete.

Embodiment 3

[0060] An admixture suitable for machine-made sand dry hard concrete on airport pavement, comprising machine-made sand airfield pavement concrete water reducer, water retaining agent, defoamer, air-entraining agent and water, the content of each component by weight is: machine-made 30 parts of concrete water reducer for sandy airport pavement; 0.02 part of water retaining agent; 0.01 part of defoamer; 0.1 part of air-entraining agent;

[0061] Machine-made sand airport pavement concrete superplasticizer is polycarboxylate high-performance superplasticizer with a solid content of 40-45% and a water-reducing rate of 20-25%. The machine-made sand airport pavement concrete water reducer has introduced functional small monomers through molecular structure design and process optimization. The machine-made sand airport pavement concrete water reducer not only has a suitable water reducing rate, but also has good mud resistance and plastic protection effect, and can play a role in red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com