Cleaning solution suitable for plate heat exchanger and preparation method thereof

A technology of plate heat exchanger and cleaning liquid, which is applied in the field of cleaning liquid, and can solve problems such as high water pressure, difficulty in achieving cleaning effect, and veneer cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

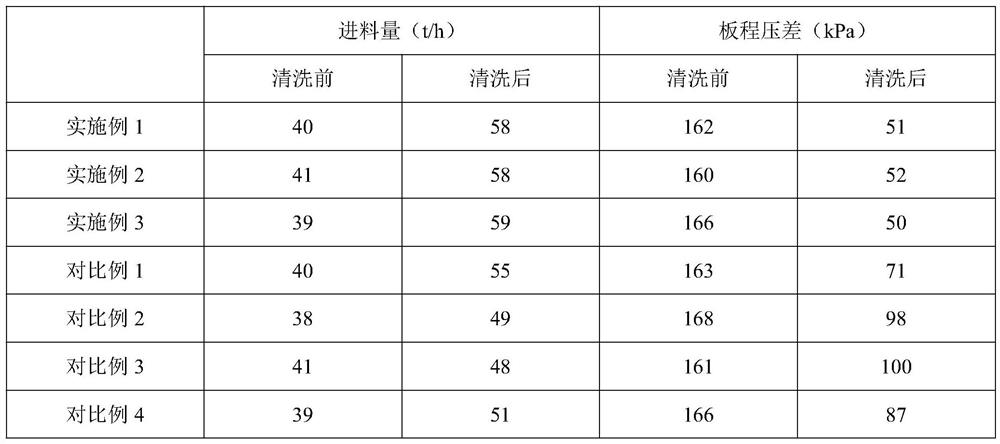

Examples

Embodiment 1

[0032] The preparation method of the cleaning liquid suitable for plate heat exchangers, the specific steps are as follows:

[0033] (1) First crush the glass into glass powder, then make the glass powder into glass microspheres, corrode to obtain porous glass microspheres, and then use N-(β-aminoethyl)-γ-aminopropylmethyl di Methoxysilane is modified to obtain modified porous glass beads;

[0034] (2) Then the isocyanate-terminated prepolymer is added to the dispersion liquid, dispersed, and modified porous glass beads are added during the dispersion process to obtain polyurethane-porous glass composite beads;

[0035] (3) Dissolve ethylenediaminetetraacetic acid in boiling water, cool naturally to room temperature, add sulfamic acid, citric acid, copper sulfate, stir until dissolved, then add 1-aminoethyl-3-methylimidazole bis( Trifluoromethanesulfonyl) imide salt, ultrasonically dispersed evenly to obtain a premixed solution;

[0036] (4) Finally, add ferric ferrocyanide ...

Embodiment 2

[0048] The preparation method of the cleaning liquid suitable for plate heat exchangers, the specific steps are as follows:

[0049] (1) First crush the glass into glass powder, then make the glass powder into glass microspheres, corrode to obtain porous glass microspheres, and then use N-(β-aminoethyl)-γ-aminopropylmethyl di Methoxysilane is modified to obtain modified porous glass beads;

[0050] (2) Then the isocyanate-terminated prepolymer is added to the dispersion liquid, dispersed, and modified porous glass beads are added during the dispersion process to obtain polyurethane-porous glass composite beads;

[0051] (3) Dissolve ethylenediaminetetraacetic acid in boiling water, cool naturally to room temperature, add sulfamic acid, citric acid, copper sulfate, stir until dissolved, then add 1-aminoethyl-3-methylimidazole bis( Trifluoromethanesulfonyl) imide salt, ultrasonically dispersed evenly to obtain a premixed solution;

[0052] (4) Finally, add ferric ferrocyanide ...

Embodiment 3

[0064] The preparation method of the cleaning liquid suitable for plate heat exchangers, the specific steps are as follows:

[0065] (1) First crush the glass into glass powder, then make the glass powder into glass microspheres, corrode to obtain porous glass microspheres, and then use N-(β-aminoethyl)-γ-aminopropylmethyl di Methoxysilane is modified to obtain modified porous glass beads;

[0066] (2) Then the isocyanate-terminated prepolymer is added to the dispersion liquid, dispersed, and modified porous glass beads are added during the dispersion process to obtain polyurethane-porous glass composite beads;

[0067] (3) Dissolve ethylenediaminetetraacetic acid in boiling water, cool naturally to room temperature, add sulfamic acid, citric acid, copper sulfate, stir until dissolved, then add 1-aminoethyl-3-methylimidazole bis( Trifluoromethanesulfonyl) imide salt, ultrasonically dispersed evenly to obtain a premixed solution;

[0068] (4) Finally, add ferric ferrocyanide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com