Preparation method of modified silicon wafer loading material and application of modified silicon wafer loading material in cell culture

A technology for loading materials and silicon wafers, applied in cell culture supports/coatings, general culture methods, biochemical equipment and methods, etc. Adhesion and other problems, to achieve the effect of favorable adhesion growth, industrialized large-scale production, and multi-loading area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

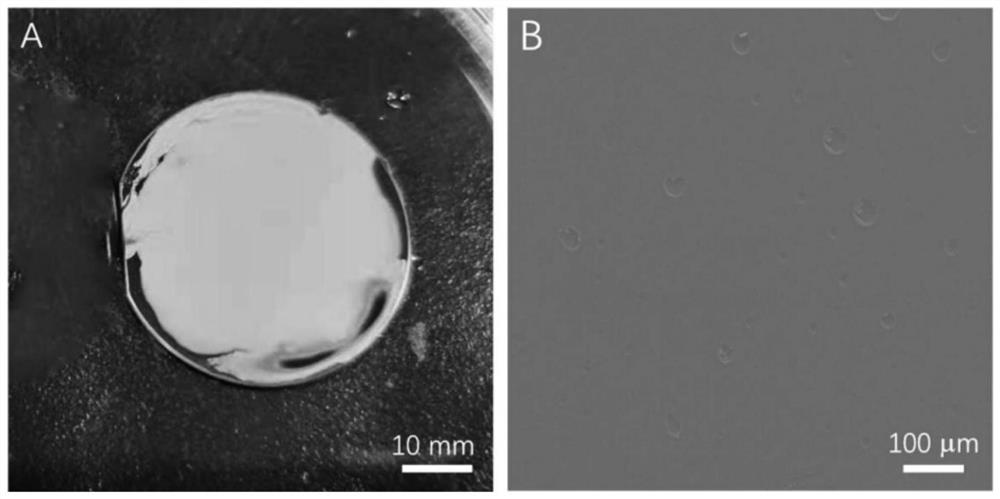

[0032] The preparation of embodiment 1 modified silicon chip support material

[0033] (1) Weigh 5g of NaOH solid, dissolve it in 100mL of 75% ethanol solution to prepare alkali washing solution, place silicon chip (circular silicon chip with a diameter of 32mm) in the above alkali washing solution for 3h, dry and place Sterilize under high temperature and high pressure at 120°C for 30 minutes, and put it in an ultra-clean bench for use after sterilization.

[0034](2) Measure 9mL of 30% hydrogen peroxide and 21mL of concentrated sulfuric acid with a clean graduated cylinder, drain with a glass rod, slowly add hydrogen peroxide into the concentrated sulfuric acid solution, and stir while adding, to obtain concentrated sulfuric acid and hydrogen peroxide Soak the silicon chip treated in step (1) in the above mixed solution of concentrated sulfuric acid and hydrogen peroxide, treat for 3h, then rinse the silicon chip with deionized water, 10mL each time, rinse 3 times, 1 minute...

Embodiment 2

[0040] The preparation of embodiment 2 modified silicon chip support materials

[0041] Steps (1)-(5) are the same as in Example 1;

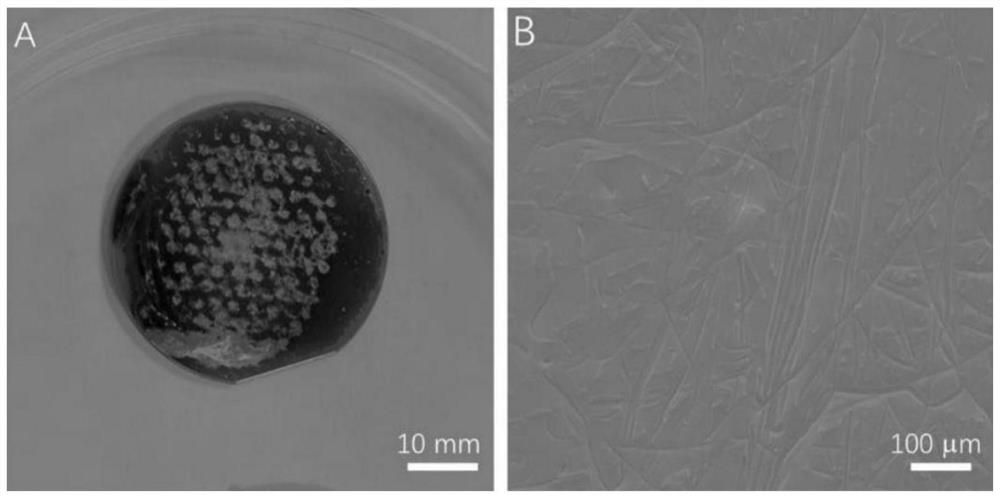

[0042] (6) Soak the dried silicon wafer in 90% ethanol solution at 80°C for 60 minutes, then place a clean PP non-woven fabric in a glass dish, and press the gelatin side of the silicon wafer on the PP non-woven fabric. Spin cloth, and use 500g weight to gently press down on the silicon wafer. After 24 hours, gently uncover the PP film, wash the silicon wafer with 5mL of absolute ethanol, wash 3 times in total, 1 minute each time, and then soak the silicon wafer in an absolute ethanol solution containing 0.25% glutaraldehyde for 30 minutes After treatment, wash with normal temperature absolute ethanol or dioxane (first wash 3 times with 5mL normal temperature absolute ethanol, 1 minute each time, then wash 3 times with 5mL normal temperature dioxane, 1 minute each time) , and finally placed in an oven at 37°C for drying treatment, and stored i...

Embodiment 3

[0044] The preparation of embodiment 3 modified silicon chip support materials

[0045] The preparation method is the same as in Example 2, the difference is that the PP film is replaced by PET commercial carrier, PET non-woven fabric, sampling screen, cell screen, and a gelatin coating with a special topological structure is prepared on the surface of the silicon chip , to prepare modified silicon wafer loading materials with various special topological structures.

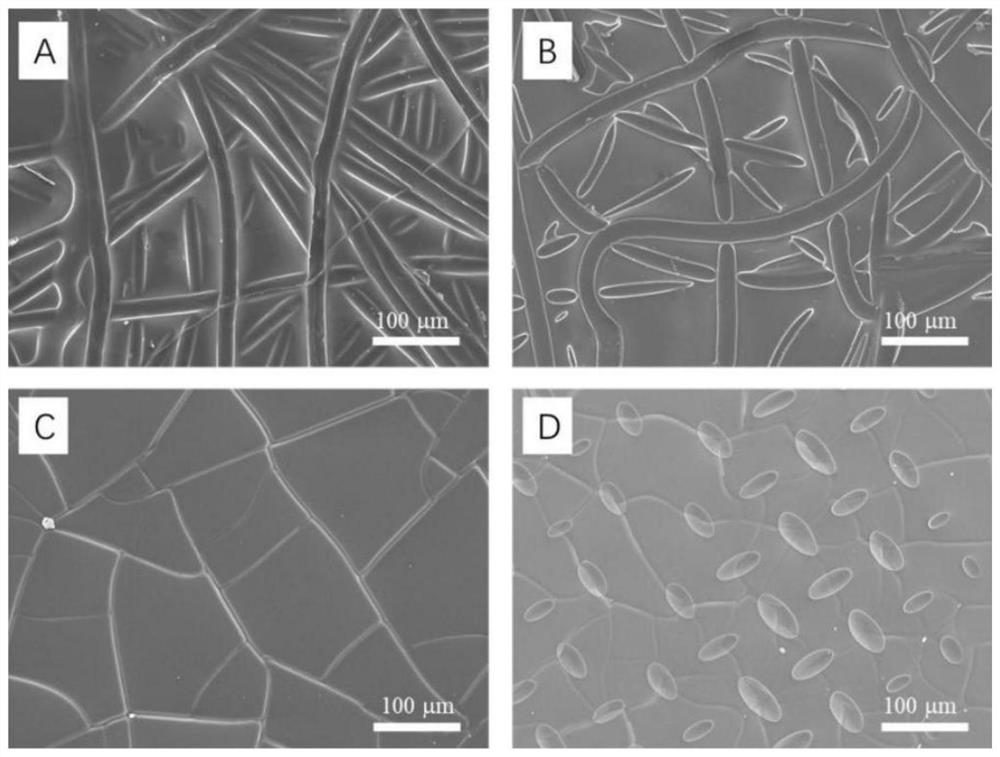

[0046] The microscopic morphology of the prepared modified silicon wafer-loaded materials with various special topological structures (PET non-woven fabric, PP non-woven fabric, sampling screen, cell screen) was observed. The SEM images are as follows: Figure 5 Shown: It can be seen that each group of embossed patterns is a topological structure with a special shape, in which groups A and B form a fiber structure with a sense of hierarchy, while C and D are patterns prepared through a screen, similar to those fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com