Preparation of concentration gradient magnesium-doped lithium-rich manganese-based oxide positive electrode material and lithium battery application of concentration gradient magnesium-doped lithium-rich manganese-based oxide positive electrode material

A lithium-rich manganese-based, concentration gradient technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems affecting cycle stability, good sphericity, less gradients, etc., and achieve low raw material costs , Maintain stability and high matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

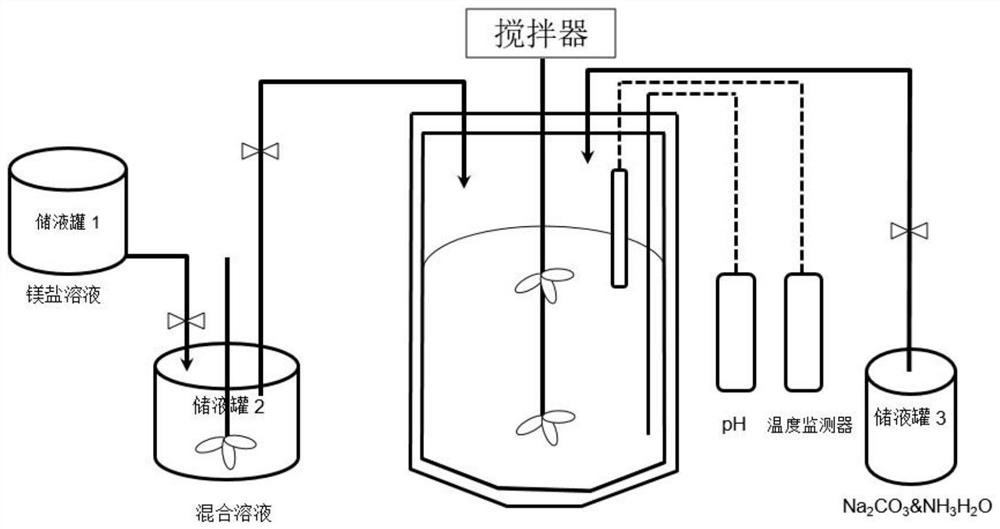

[0034] Preparation of a lithium-rich manganese-based oxide concentration gradient magnesium-doped modified positive electrode material, setting x = 0.05, that is, the chemical formula is Li 1.1 mn 0.54 Ni 0.13 co 0.13 Mg 0.05 o 2 .

[0035] Step (1): Prepare 1L transition metal mixed salt solution A with a concentration of 2mol L -1 , where manganese nickel cobalt salts are MnSO 4 、NiSO 4 、CoSO 4 The mixture of Mn:Ni:Co molar ratio is 0.54:0.13:0.13. Add another 1L of ammonia water with a concentration of 0.2mol L -1 、Na2 CO 3 The concentration is 2mol L -1 Mix solution B and 0.5LMgSO 4 The concentration is 0.25mol L -1 solution C.

[0036] Step (2): Use circulating water to control the temperature of the reactor at 55° C., set the stirring speed of the stirring paddle in the reactor to 800 rpm, and then use solution B to adjust the pH value to 7.8. After the pH of the system is stable, use a peristaltic pump to add solution C to the constantly stirring solution...

Embodiment 2

[0041] Preparation of a lithium-rich manganese-based oxide concentration gradient magnesium-doped modified cathode material, setting x = 0.07, that is, the chemical formula is Li 1.06 mn 0.54 Ni 0.13 co 0.13 Mg 0.07 o 2 .

[0042] Step (1): Prepare 1L transition metal mixed salt solution A with a concentration of 1mol L -1 , where manganese-nickel-cobalt salt is MnSO 4 、NiSO 4 、CoSO 4 The mixture, the molar ratio is 0.54:0.13:0.13. Add another 1L of ammonia water with a concentration of 0.4mol·L -1 、Na 2 CO 3 The concentration is 1mol L -1 Mix solution B and 175mL MgSO 4 The concentration is 0.5mol L -1 solution C.

[0043] Step (2): Use circulating water to control the temperature in the reactor at 55° C., set the stirring speed of the stirring paddle in the reactor to 900 rpm, and then use solution B to adjust the pH to 8.0. After the pH of the system is stable, use a peristaltic pump to add solution C to the constantly stirring solution A, and then add solut...

Embodiment 3

[0048] Preparation of a lithium-rich manganese-based oxide concentration gradient magnesium-doped modified positive electrode material, setting x = 0.05, that is, the chemical formula is Li 1.1 mn 0.54 Ni 0.13 co 0.13 Mg 0.05 o 2 .

[0049] Step (1): Prepare 1L transition metal mixed salt solution A with a concentration of 1mol L -1 , where manganese nickel cobalt salt is Mn(NO 3 ) 2 , Ni(NO 3 ) 2 , Co(NO 3 ) 2 The mixture, the molar ratio is 0.54:0.13:0.13. Add another 1L of ammonia water with a concentration of 1mol·L -1 、Na 2 CO 3 The concentration is 1mol L -1 Mix solution B and 31mL MgSO 4 The concentration is 2mol L -1 solution C.

[0050] Step (2): Use circulating water to control the temperature in the reactor at 60° C., set the stirring speed of the stirring paddle in the reactor to 1000 rpm, and then use solution B to adjust the pH to 8.0. After the pH of the system is stabilized, use a peristaltic pump to add solution C to the constantly stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com