High-self-cleaning super-smooth anti-pollution flashover coating and preparation method thereof

An anti-fouling flashover coating, self-cleaning technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of loss of superhydrophobicity, coating failure, loss of low surface energy, etc., to achieve good chemical corrosion resistance and corrosion resistance Aging resistance, good anti-icing performance, easy spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

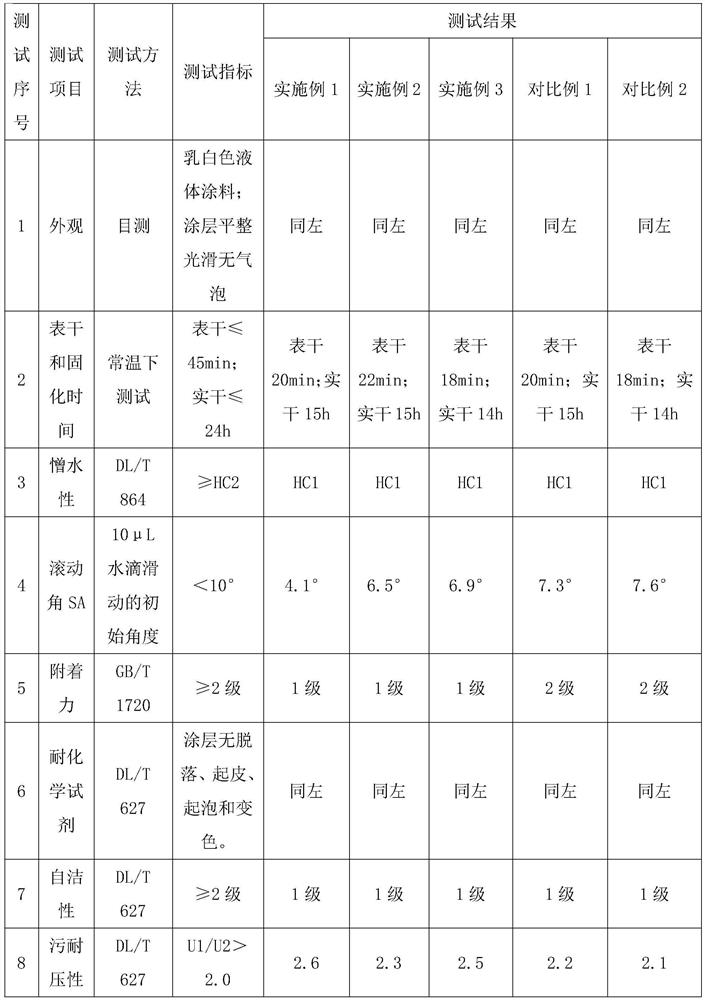

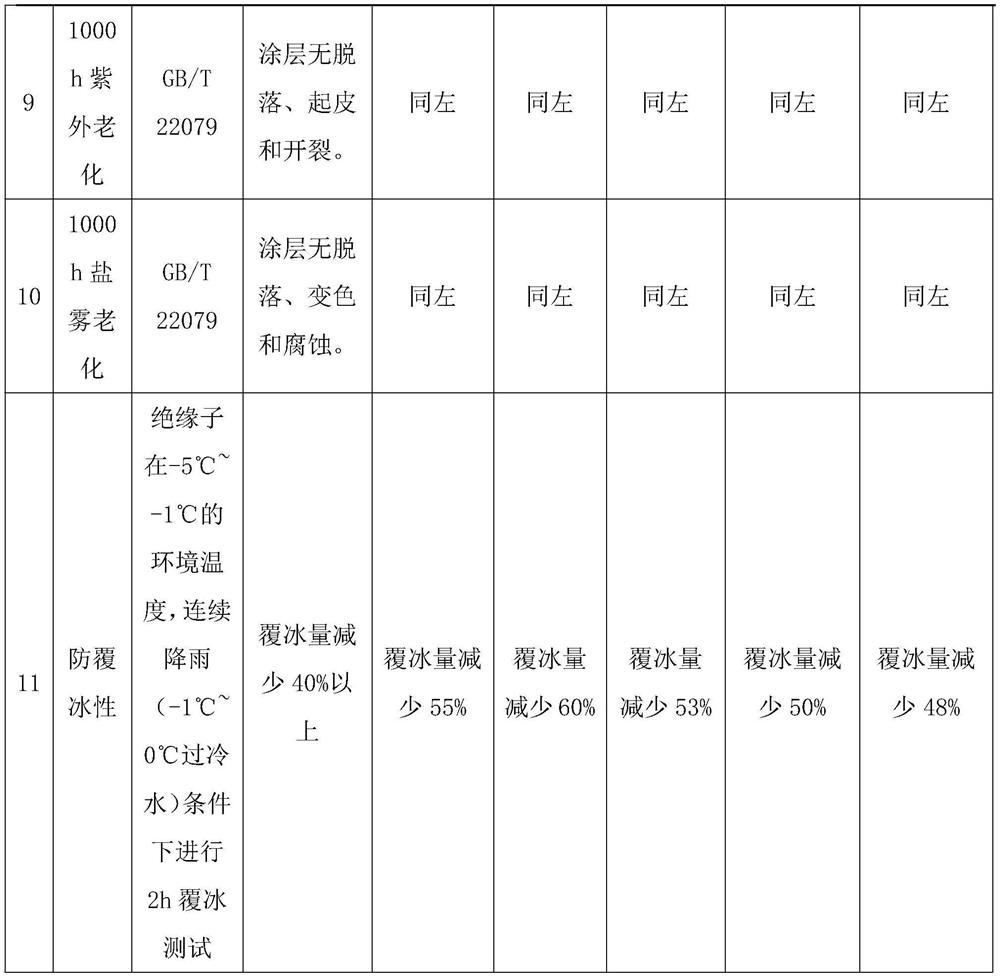

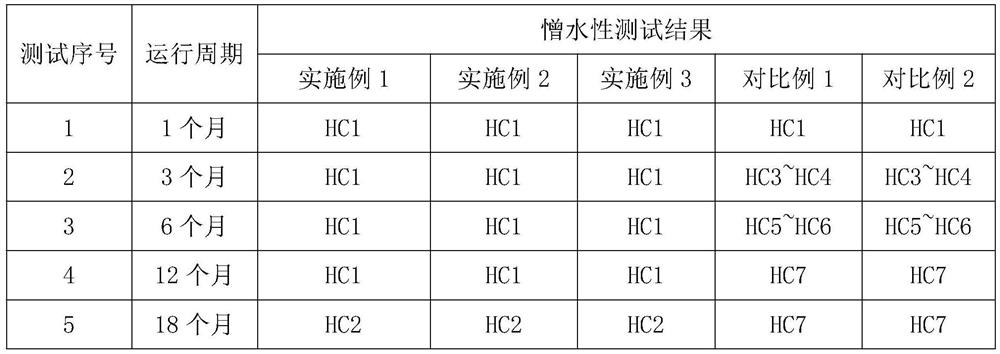

Examples

Embodiment 1

[0029] A kind of high self-cleaning super-slippery antifouling flashover paint, by hydroxyl silicone oil (lubricating oil), methyl silicone oil (lubricating oil), small molecular silicone oil (lubricating oil), fluorocarbon resin, butyl acetate (solvent), hydrophobic SiO 2, polytetrafluoroethylene PTFE, perfluorodecyltrimethoxysilane (silane coupling agent), the mass percentage of each raw material is: hydroxy silicone oil (lubricating oil) 3.6%, methyl silicone oil (lubricating oil) 3.6% %, small molecule silicone oil (lubricating oil) 3.6%, fluorocarbon resin 12.6%, butyl acetate (solvent) 71.9%, hydrophobic SiO 2 1.8%, polytetrafluoroethylene PTFE 1.8%, perfluorodecyltrimethoxysilane (silane coupling agent) 1.1%. The small molecule silicone oil refers to silicone oil with a viscosity lower than 150cst.

[0030] According to the above technical scheme, the hydrophobic SiO 2 The preparation method is: according to SiO 2 , alcohol aqueous solution (the mass ratio of alcohol...

Embodiment 2

[0038] A kind of high self-cleaning type ultra-slip antifouling flashover paint, by hydroxyl silicone oil (lubricating oil), methyl silicone oil (lubricating oil), fluorocarbon resin, ethyl acetate (solvent), butyl acetate (solvent), hydrophobic SiO 2 , polytetrafluoroethylene PTFE, perfluorodecyltrimethoxysilane (silane coupling agent), and the mass percentages of each raw material are: hydroxyl silicone oil (lubricating oil) 3.1%, methyl silicone oil (lubricating oil) 3.86% %, fluorocarbon resin 11.6%, ethyl acetate (solvent) 38.6%, butyl acetate (solvent) 38.6%, hydrophobic SiO 2 1.54%, polytetrafluoroethylene PTFE 1.93%, perfluorodecyltrimethoxysilane (silane coupling agent) 0.77%.

[0039] According to the above technical scheme, the hydrophobic SiO 2 The preparation method is: according to SiO 2 , alcohol aqueous solution (the mass ratio of alcohol to water is 2:1), and the mass percentages of the raw materials of silane coupling agent are: SiO 2 5%, alcohol aqueous s...

Embodiment 3

[0047] A kind of high self-cleaning super-slippery antifouling flashover paint, by hydroxyl silicone oil (lubricating oil), small molecular silicone oil (lubricating oil), fluorocarbon resin, xylene (solvent), butyl acetate (solvent), hydrophobic SiO 2 , polytetrafluoroethylene PTFE, and silane coupling agent, the mass percentage of each raw material is: hydroxyl silicone oil (lubricating oil) 9.34%, small molecule silicone oil (lubricating oil) 1.9%, fluorocarbon resin 11.24%, xylene (solvent) 22.47%, butyl acetate (solvent) 48.69%, hydrophobic SiO 2 3%, polytetrafluoroethylene 2.25%, silane coupling agent 1.11%.

[0048] The small molecule silicone oil refers to silicone oil with a viscosity lower than 150cst.

[0049] The hydrophobic SiO 2 The preparation method is: according to SiO 2 , alcohol aqueous solution (the mass ratio of alcohol to water is 3:1), and the mass percentages of the raw materials of silane coupling agent are: SiO 2 4%, alcohol aqueous solution 95%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com