Negative electrode material and preparation method and application thereof

A technology for negative electrode materials and raw materials, applied in the field of negative electrode materials and their preparation, can solve the problems of material expansion and other properties, large particle size of lithium-silicon alloy, slow reaction speed, etc., and achieve good cycle stability and synthesis reaction speed. Fast, low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

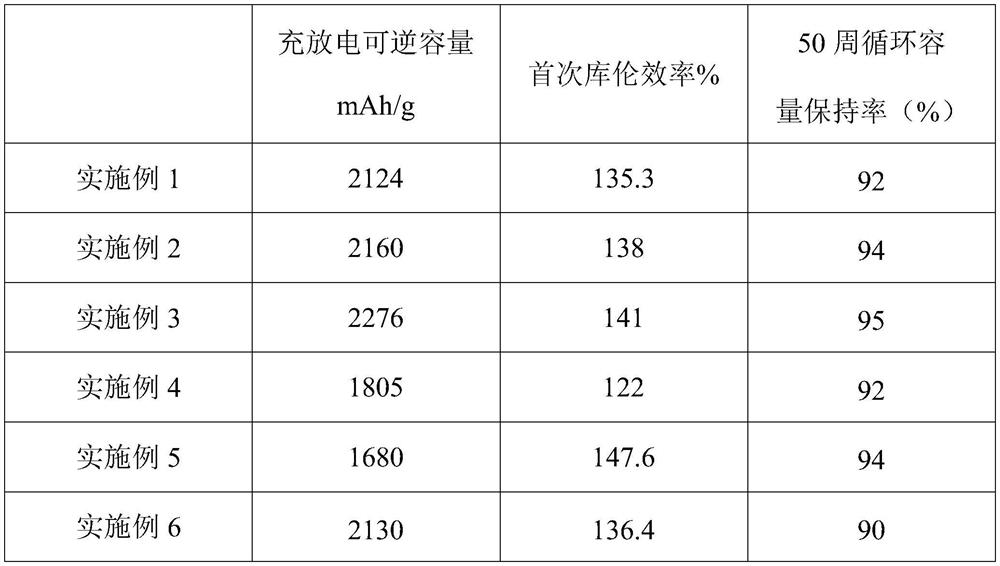

Embodiment 1

[0065] This embodiment provides a negative electrode material, the negative electrode material includes the negative electrode material includes an inner core, a first carbon coating layer coated on the surface of the inner core, and a second carbon coating layer located on the outermost layer;

[0066] Wherein, the inner core is an amorphous lithium-silicon alloy with a grain size of 100 nm, and the chemical formula of the amorphous lithium-silicon alloy is Li 12 Si 7 , the thickness of the first carbon coating layer is 20nm, and the thickness of the second carbon coating layer is 50nm.

[0067] The preparation method of the negative electrode material is as follows:

[0068] (1) Put 5g of nano-silicon with a particle size of 60nm into a CVD furnace, first pass into argon for replacement, then pass into methane for vapor phase deposition, the deposition temperature is 900 ° C, and the time is 1h to obtain the first substrate;

[0069] (2) Add LiH and the first matrix into t...

Embodiment 2

[0073] This embodiment provides a negative electrode material, the negative electrode material includes the negative electrode material includes an inner core, a first carbon coating layer coated on the surface of the inner core, and a second carbon coating layer located on the outermost layer;

[0074] Wherein, the inner core is an amorphous lithium-silicon alloy with a particle size of 120 nm, and the chemical formula of the amorphous lithium-silicon alloy is Li 3.25 Si 1 , the thickness of the first carbon coating layer is 40nm, and the thickness of the second carbon coating layer is 60nm.

[0075] The preparation method of the negative electrode material is as follows:

[0076] (1) Put 5g of nano-silicon with a particle size of 100nm into a CVD furnace, first pass into argon for replacement, and then pass into acetylene for vapor phase deposition, the deposition temperature is 1100 ° C, and the time is 4h to obtain the first substrate;

[0077] (2) Add LiH and the first ...

Embodiment 3

[0080] This embodiment provides a negative electrode material, the negative electrode material includes the negative electrode material includes an inner core, a first carbon coating layer coated on the surface of the inner core, and a second carbon coating layer located on the outermost layer;

[0081] Wherein, the inner core is a lithium-silicon alloy with a particle size of 100 nm, and the chemical formula of the lithium-silicon alloy is Li 3.75 Si, the thickness of the first carbon coating layer is 30nm, and the thickness of the second carbon coating layer is 80nm.

[0082] The preparation method of the negative electrode material is as follows:

[0083] (1) Put 5g of nano-silicon with a particle size of 70nm into a CVD furnace, first pass into argon for replacement, and then pass into ethylene for vapor phase deposition, the deposition temperature is 950 ° C, and the time is 2h to obtain the first substrate;

[0084] (2) Add LiH and the first matrix into the mixer at a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com