Method for producing malic acid

A technology of malic acid and seeds, which is applied in the biological field, can solve the problems of less fermentation liquid, slow processing speed, and high cost, and achieve the effects of high yield and purity, simple operation process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

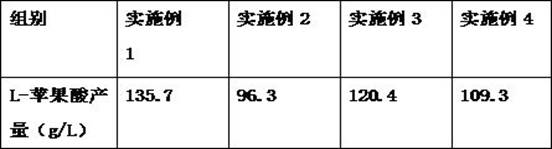

Examples

Embodiment 1

[0022] A method for producing malic acid, comprising the steps of:

[0023] Aspergillus oryzae ACCC30584 bacteria solution (concentration of 1 × 10 8 CFU / mL) according to the inoculum amount of 10% (volume ratio) into the seed tank for cultivation, at a temperature of 33 ° C, a shaker speed of 200 r / min, and culturing for 12 hours to obtain a seed liquid, wherein the medium group of the seed tank Divided into (1L): 3g sucrose, 0.2g sodium nitrate, 0.5g ammonium sulfate, 0.1g potassium dihydrogen phosphate, 0.1g dipotassium hydrogen phosphate, 0.1g manganese sulfate monohydrate, 0.01g ferrous sulfate heptahydrate, magnesium sulfate 0.01g, sodium chloride 0.01g, pH 6.0;

[0024] According to the volume ratio of seed liquid: fermenter culture medium is 1: 10, transfer in the fermenter to cultivate, temperature 33 ℃, cultivate 48h, then add calcium carbonate and natamycin, the addition of calcium carbonate is 80g / L, Natamycin The added amount of tamycin is 5 mg / L, and the fermen...

Embodiment 2

[0028] A method for producing malic acid, comprising the steps of:

[0029] Aspergillus oryzae ACCC30584 bacteria solution (concentration of 1 × 10 8 CFU / mL) according to the inoculum amount of 10% (volume ratio) into the seed tank for cultivation, at a temperature of 33 ° C, a shaker speed of 200 r / min, and culturing for 12 hours to obtain a seed liquid, wherein the medium group of the seed tank Divided into (1L): 3g sucrose, 0.2g sodium nitrate, 0.5g ammonium sulfate, 0.1g potassium dihydrogen phosphate, 0.1g dipotassium hydrogen phosphate, 0.1g manganese sulfate monohydrate, 0.01g ferrous sulfate heptahydrate, magnesium sulfate 0.01g, sodium chloride 0.01g, pH 6.0;

[0030] According to the volume ratio of seed liquid: the fermenter medium is 1: 10, transfer it to the fermenter for cultivation, temperature is 33 ℃, cultivate 48h, then add calcium carbonate, the addition of calcium carbonate is 80g / L, continue to ferment for 36h, then control The temperature is 39°C, the p...

Embodiment 3

[0034] A method for producing malic acid, comprising the steps of:

[0035] Aspergillus oryzae ACCC30584 bacteria solution (concentration of 1 × 10 8CFU / mL) according to the inoculum amount of 10% (volume ratio) into the seed tank for cultivation, at a temperature of 33 ° C, a shaker speed of 200 r / min, and culturing for 12 hours to obtain a seed liquid, wherein the medium group of the seed tank Divided into (1L): 3g sucrose, 0.2g sodium nitrate, 0.5g ammonium sulfate, 0.1g potassium dihydrogen phosphate, 0.1g dipotassium hydrogen phosphate, 0.1g manganese sulfate monohydrate, 0.01g ferrous sulfate heptahydrate, magnesium sulfate 0.01g, sodium chloride 0.01g, pH 6.0;

[0036] According to the volume ratio of seed liquid: fermenter culture medium is 1: 10, transfer in the fermenter to cultivate, temperature 33 ℃, cultivate 48h, then add calcium carbonate and natamycin, the addition of calcium carbonate is 80g / L, Natamycin The added amount of tamycin is 5 mg / L, and the ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com