A kind of preparation method and application of silver-doped copper nanosheet catalyst

A catalyst and copper nanotechnology, which is applied in the field of preparation of silver-doped copper nanosheet catalysts, can solve the problems of low catalytic yield, low catalyst selectivity, low Faraday efficiency, etc., and achieve clean and pollution-free products, low cost, The effect of reducing the reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

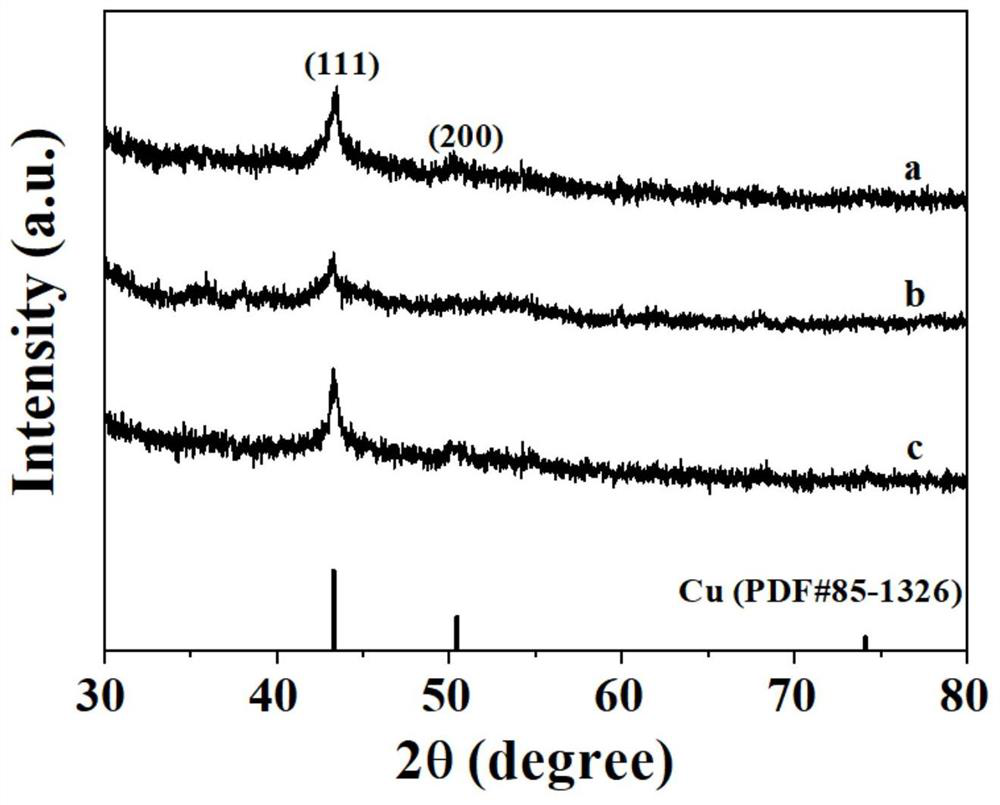

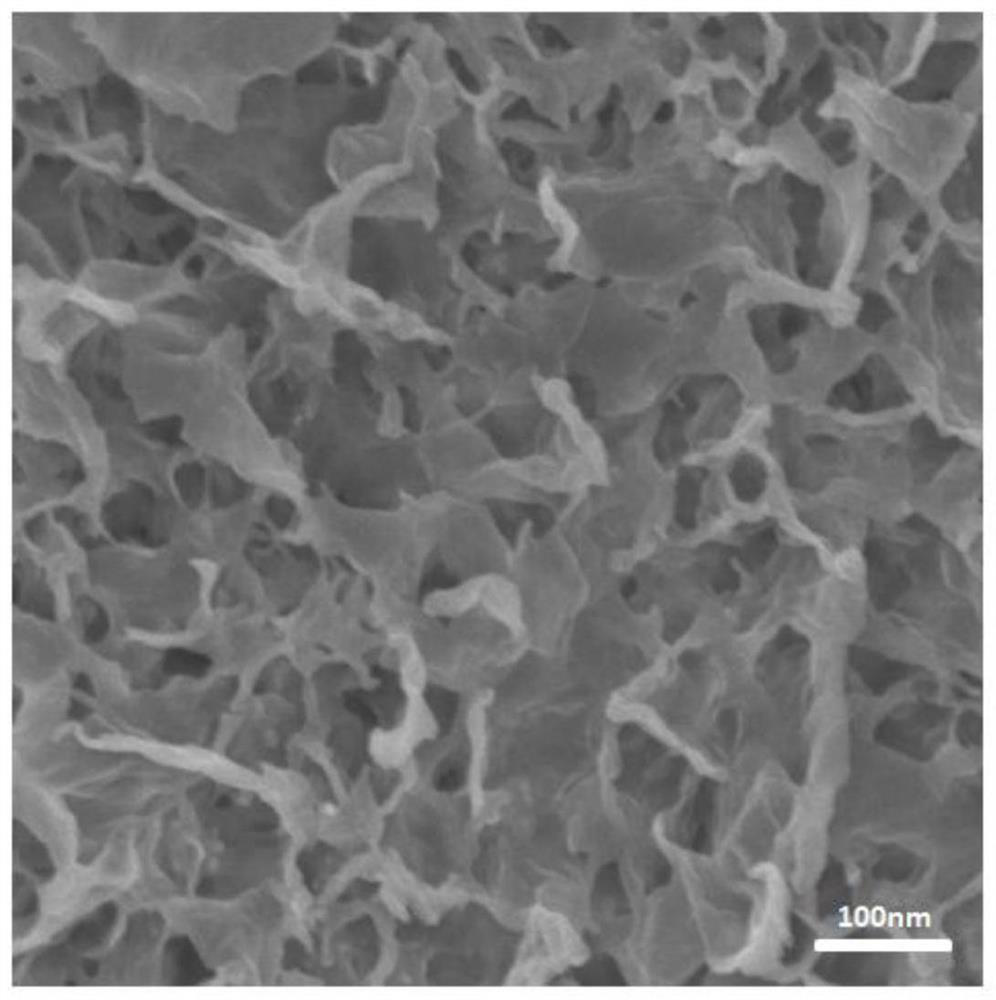

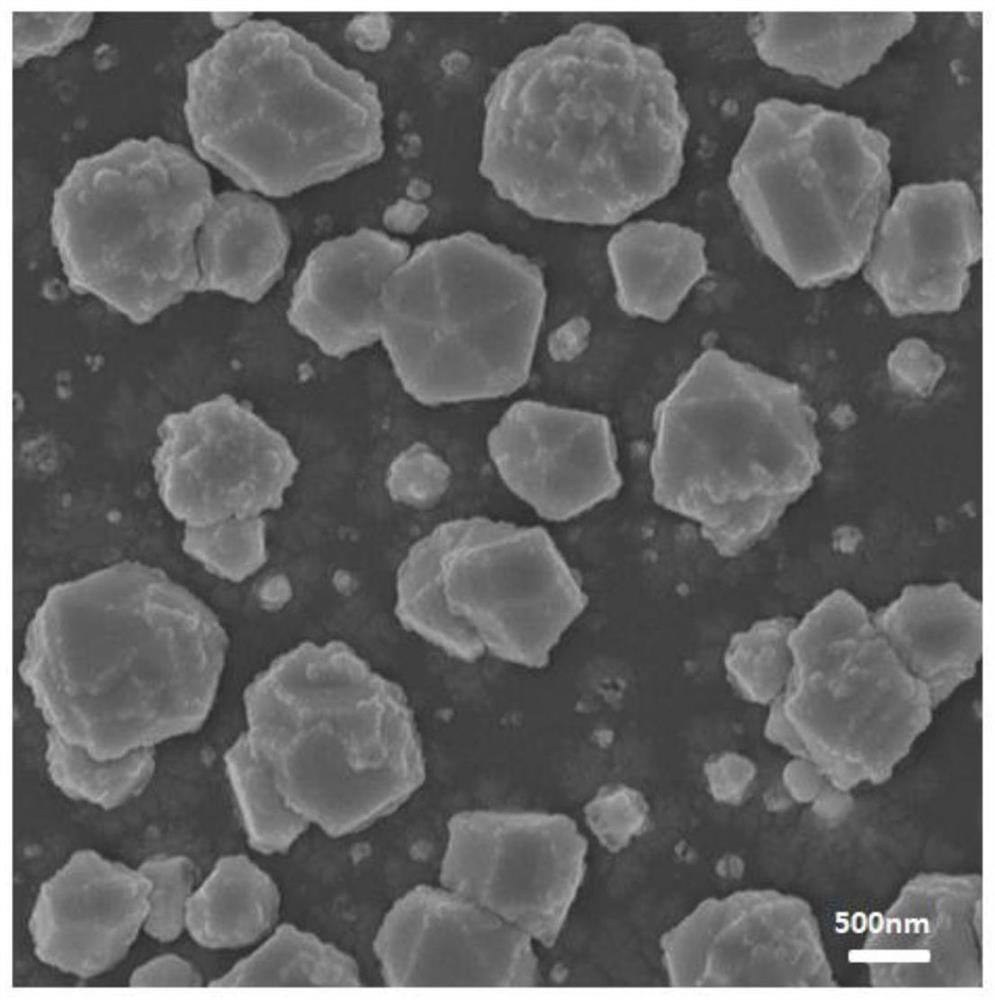

[0034] Weigh 0.8~1.6g of CuSO respectively 4 ·5H 2 O and 20-50 mg of 3,5-diamino-1,2,4-triazole (DAT), respectively, were dissolved in 15-20 ml of deionized water; then the two reactant solutions were mixed and stirred uniformly, and then added to Add 0.5mM AgNO to the mixed solution 3 solution, after fully stirring, use 1M H 2 SO 4 The pH of the solution was adjusted to 2 to 3; then the mixed solution was placed in a three-electrode system, with carbon paper as the working electrode, Ag / AgCl electrode as the reference electrode, and graphite electrode as the counter electrode, and the electro-deposition of the catalyst was carried out by chronoamperometry. , set the deposition voltage to -2 to -4 mA, and set the deposition time to 0.5 to 2 min to obtain Ag-Cu / CP. DAT composite material.

Embodiment 2

[0044] Ag-Cu / CP prepared in Example 1 was used respectively DAT Composite material, Ag-Cu / CP prepared in Comparative Example 1 DAT The Ag-Cu / CP composite material prepared in Comparative Example 2 was used as a catalyst for electrochemical ammonia synthesis reaction.

[0045] The electrochemical ammonia synthesis reaction is carried out in an H-type electrolytic cell. The working electrode is the carbon paper loaded with catalyst and the Ag / AgCl electrode as the reference electrode is in the same room, and the platinum sheet electrode is used as the counter electrode in another room. The protons are separated by a proton exchange membrane. An equal amount of 0.1M Na was added to the two chambers 2 SO 4 As an electrolyte, high-purity argon and high-purity nitrogen were respectively introduced into the electrolyte for 30 min each before the electrochemical nitrogen reduction reaction to synthesize ammonia to remove the impurity gas in the electrolyte. Nitrogen reduction synt...

Embodiment 3

[0047] Weigh 0.45-0.9 g of NaOH, dissolve it in 5-10 mL of deionized water, add 10-20 mL of sodium hypochlorite to the solution after fully dissolving, stir well to obtain a color developing solution a; weigh 1-2 g of salicylic acid and 0.8~1.6g of NaOH, dissolve in 20~40mL deionized water, fully dissolve to obtain color developing solution b; Weigh 0.1~0.2g of nitroprusside and dissolve in 10~20mL deionized water, fully dissolve to obtain color development liquid c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com