Continuous crystallization micro-nano chemical chip and application thereof

A chemical and micro-nano technology, applied in the field of continuous crystallization of micro-nano chemical chips, can solve problems such as inability to realize continuous production of products, product quality differences between batches, and damage to crystallization devices, so as to facilitate crystallization, improve crystal quality, and prevent Effects of deposition and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

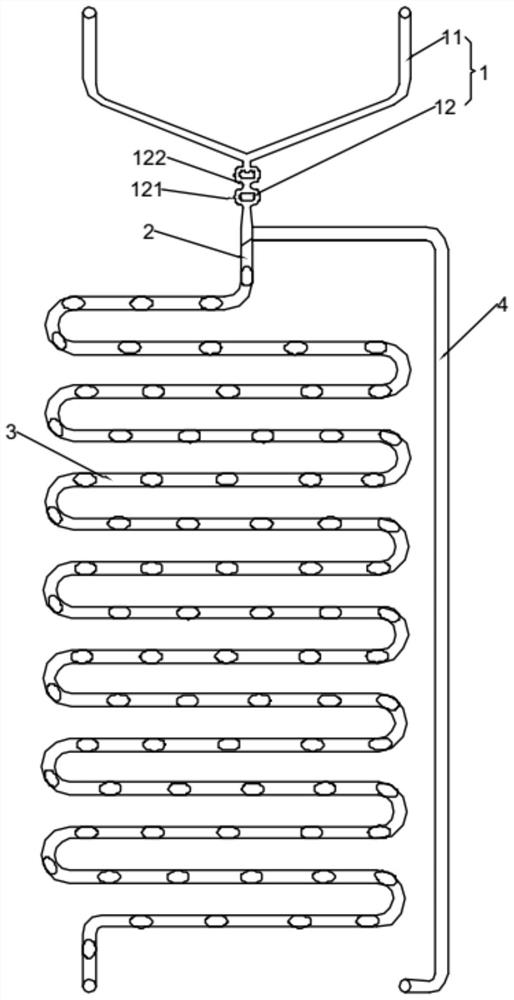

[0046] The micro-nano chemical chip is provided with two injection channels 11, such as figure 1 As shown, the liquid injection channel 11 on the left is 300 μm deep, 520 μm wide, and 10 mm long; the liquid injection channel 11 on the right is 300 μm deep, 520 μm wide, and 10 mm long; the liquid inlet channel 4 is 300 μm deep, 700 μm wide, and 25 mm long; continuous crystallization Section 3 is 300 μm deep, 800 μm wide, and 200 mm long. The mixing channel 12 is 2 mm long and includes 2 splitting units 121 and 2 recombining units 122 . The base plate and cover plate are made of 2 mm thick glass plates.

[0047] Step 1. First place the micro-nano chemical chip under the reaction condition of an ambient temperature of 20°C, and then inject a sodium hydroxide solution with a concentration of 4.5mol / L into the liquid injection channel 11 on the left at a flow rate of 0.01ml / min. The hydrochloric acid solution with a concentration of 4.5mol / L is injected into the injection channel 1...

Embodiment 2

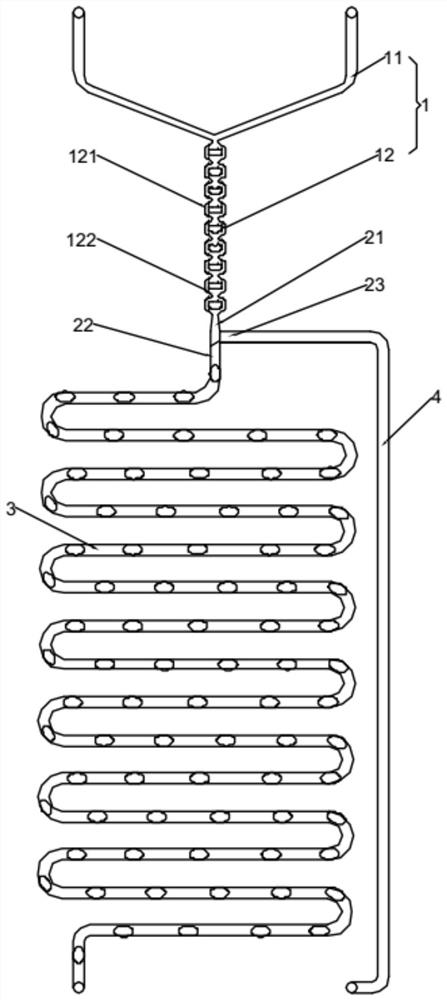

[0052] The micro-nano chemical chip is provided with two liquid injection channels 11, and the schematic diagram of the structure is as follows: figure 2 As shown, the liquid injection channel 11 on the left is 200 μm deep, 800 μm wide, and 14 mm long; the liquid injection channel 11 on the right is 200 μm deep, 800 μm wide, and 14 mm long; the liquid inlet channel 4 is 200 μm deep, 800 μm wide, and 68 mm long; continuous crystallization Section 3 is 200 μm deep, 800 μm wide, and 1000 mm long. The mixing channel 12 is 5.6 mm long and includes 9 split units 121 and 9 recombination units 122 . The base plate and cover plate are 2 mm thick glass plates.

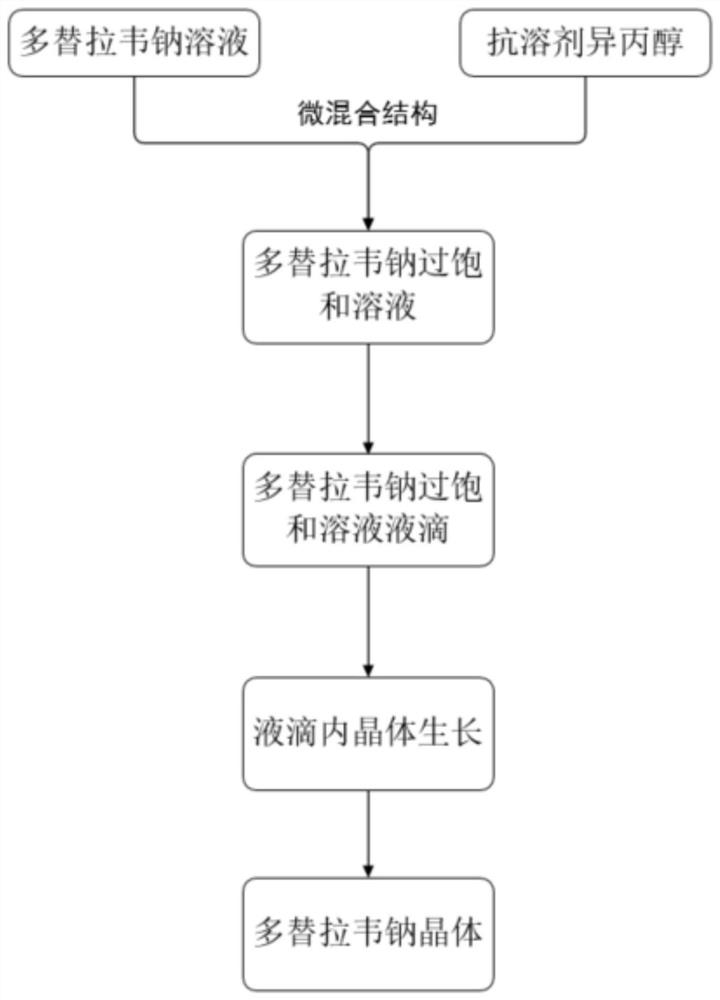

[0053] Step 1. First place the micro-nano chemical chip under the reaction conditions of an ambient temperature of 25°C, and then inject the dolutegravir sodium solution with a concentration of 0.01g / ml into the injection solution on the left at a flow rate of 0.05ml / min Channel 11, isopropanol is injected into the injection ch...

Embodiment 3

[0058] The micro-nano chemical chip is provided with two liquid injection channels 11, and the schematic diagram of the structure is as follows: figure 2 As shown, the liquid injection channel 11 on the left is 200 μm deep, 800 μm wide, and 14 mm long; the liquid injection channel 11 on the right is 200 μm deep, 800 μm wide, and 14 mm long; the liquid inlet channel 4 is 200 μm deep, 800 μm wide, and 68 mm long; continuous crystallization Section 3 is 200 μm deep, 800 μm wide, and 444 mm long. The mixing channel 12 is 5.6 mm long and includes 9 splitting units 121 and 9 recombining units 122 . The base plate and cover plate are 2 mm thick glass plates.

[0059] Step 1. First place the micro-nano chemical chip under the reaction conditions of an ambient temperature of 70°C, and then inject the dolutegravir solution with a concentration of 0.00865g / ml into the injection channel on the left at a flow rate of 0.05ml / min 11. Inject sodium hydroxide with a concentration of 0.019878g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com