Glass mixture ingredient moisture control process and glass raw material stirrer

A glass raw material and mixer technology, which is applied to mixers, mixer accessories, mixers with a rotary stirring device, etc., can solve the problems that the glass raw material mixer cannot achieve moisture control, and the moisture control of the mixture is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

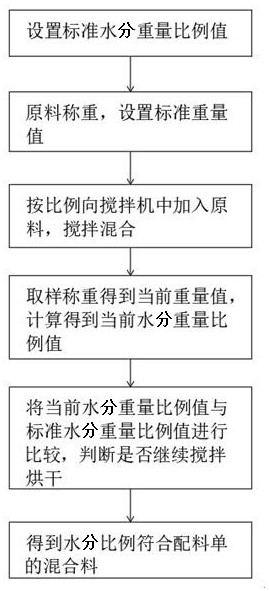

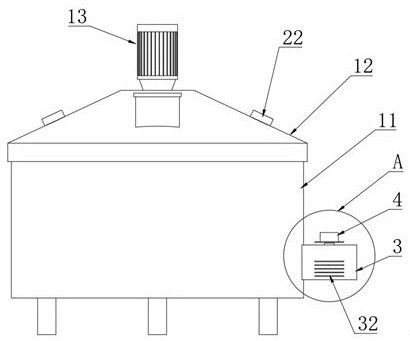

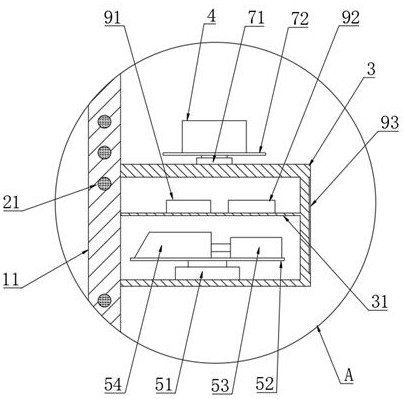

[0087] see Figure 1-8 , Embodiment 2: a kind of glass mixture batching moisture control technology, uses a kind of glass raw material mixer that can control moisture described in embodiment 1, technological process is as follows:

[0088] S1: Obtain the water weight proportion data according to the glass ingredient list, and input the water weight proportion data to the processor 91 through the touch screen 93 as a standard water weight proportion value.

[0089] During specific implementation, in order to make the moisture ratio of the mixture finally obtained approach the optimal ratio given by the ingredient list, an upper limit and a lower limit are set for the standard moisture weight ratio value in the S1 step.

[0090] S2: Remove the weighing box 4 from the bottom of the casing 3, and fill the weighing box 4 with various raw materials according to the fixed weight ratio according to the glass ingredient list.

[0091] S3: Place the weighing box 4 on the second loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com