Method for synthesizing o-phenylenediamine through continuous ammoniation

A technology for o-phenylenediamine and chemical synthesis, which is applied in the field of continuous ammoniated synthesis of o-phenylenediamine, can solve the problems of poor product quality and low yield of o-phenylenediamine, and achieves increased energy consumption, improved catalytic activity, excellent The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for continuous ammoniation synthesis of o-phenylenediamine, comprising the steps of:

[0023] Add o-dichlorobenzene into the continuous reaction kettle disclosed in the invention patent CN201710645689.7, add liquid ammonia while stirring, raise the temperature to 85°C, control the reaction pressure to 5MPa, add the catalyst, react for 6h, after the reaction is completed, at 100°C Separate the oil phase, vacuum distill to obtain o-phenylenediamine, control the mol ratio of o-dichlorobenzene and liquefied ammonia to be 1:5, the consumption of catalyst is 1% of o-dichlorobenzene weight, the yield of o-phenylenediamine is 92.5%, with a purity of 99.1%;

[0024] The catalyst is formed by mixing cuprous chloride and a synergistic body according to a weight ratio of 3:1, and the synergistic body comprises the following steps to make:

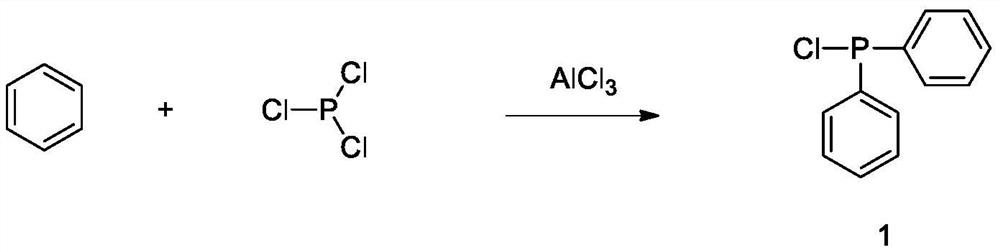

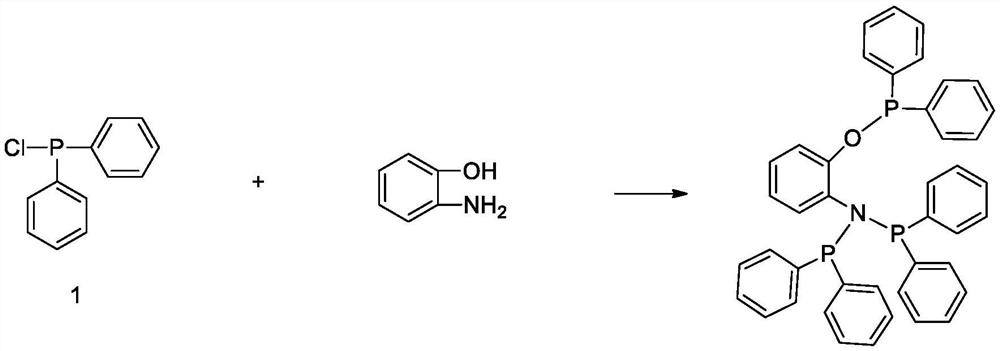

[0025] Step S1, add benzene into a three-necked flask, add phosphorus trichloride and aluminum trichloride in turn, feed nitrogen gas...

Embodiment 2

[0029] A method for continuous ammoniation synthesis of o-phenylenediamine, comprising the steps of:

[0030] Add o-dichlorobenzene into the continuous reaction kettle disclosed in the invention patent CN201710645689.7, add liquid ammonia while stirring, raise the temperature to 85°C, control the reaction pressure to 5MPa, add the catalyst, react for 6h, after the reaction is completed, at 100°C Separate the oil phase, vacuum distill to obtain o-phenylenediamine, control the mol ratio of o-dichlorobenzene and liquefied ammonia to be 1: 6, the consumption of catalyst is 1.2% of o-dichlorobenzene weight, the yield of o-phenylenediamine is 92.8%, with a purity of 99.1%;

[0031] Described catalyst is that cuprous chloride and synergistic body are mixed according to the weight ratio of 3.5: 1, and described synergistic body comprises the following steps to make:

[0032] Step S1, add benzene into a three-necked flask, add phosphorus trichloride and aluminum trichloride in turn, f...

Embodiment 3

[0036] A method for continuous ammoniation synthesis of o-phenylenediamine, comprising the steps of:

[0037] Add o-dichlorobenzene into the continuous reaction kettle disclosed in the invention patent CN201710645689.7, add liquid ammonia while stirring, raise the temperature to 90°C, control the reaction pressure to 5.5MPa, add the catalyst, react for 6h, and after the reaction is completed, the reaction temperature is 100°C The oily phase is separated under vacuum distillation to obtain o-phenylenediamine, the mol ratio of controlling o-dichlorobenzene and liquefied ammonia is 1: 8, the consumption of catalyst is 1.4% of the weight of o-dichlorobenzene, and the yield of o-phenylenediamine 92.3% and a purity of 99.5%;

[0038] Described catalyst is that cuprous chloride and synergistic body are mixed according to the weight ratio of 4.5: 1, and described synergistic body comprises the following steps to make:

[0039] Step S1, add benzene into a three-necked flask, add phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com