Photochromic polyester material and preparation method thereof

A polyester material, photochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of high addition amount of photochromic microcapsules, low spiropyran content, and indistinct color changes, etc. Better photochromic effect and higher fiber washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

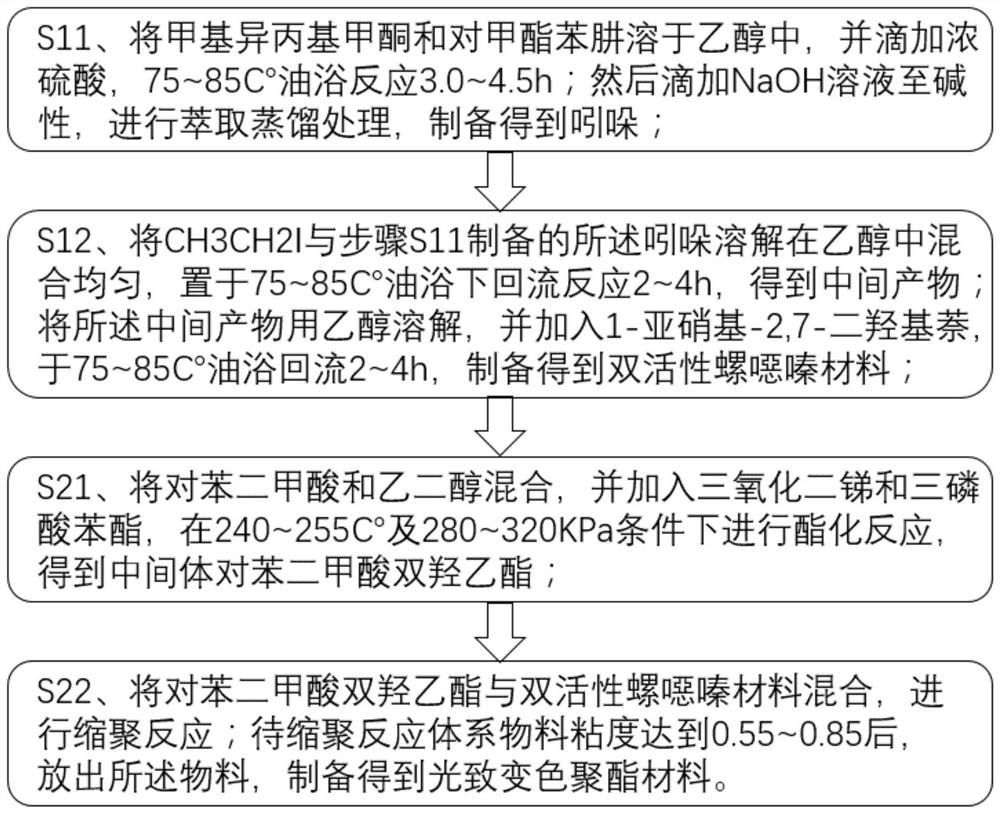

[0033] see figure 1 As shown, the invention provides a kind of preparation method of photochromic polyester material, comprises the steps:

[0034] S1. Preparation of dual-active spirooxazine materials:

[0035] S11. Dissolve methyl isopropyl ketone and p-methylphenylhydrazine in ethanol according to a predetermined molar ratio to obtain a first mixed solution, and add concentrated sulfuric acid dropwise to the first mixed solution, at 75-85°C Reacting in an oil bath for 3.0 to 4.5 hours; then adding NaOH solution dropwise to the first mixed solution to make it alkaline, and performing extraction and distillation treatment to prepare indole;

[0036] S12. Change CH 3 CH 2 I and the indole prepared in step S11 were dissolved in ethanol and mixed uniformly, placed in an oil bath at 75-85°C for reflux reaction for 2-4 hours, and purified to obtain an intermediate product; the intermediate product was dissolved in ethanol, and added A predetermined amount of 1-nitroso-2,7-dihydr...

Embodiment 1

[0049] S1. Preparation of dual-active spirooxazine materials:

[0050] Slowly add 1 mol of methyl isopropyl ketone distilled under atmospheric pressure into 1 mol of p-methyl phenylhydrazine, use ethanol as a solvent, add the catalyst concentrated sulfuric acid dropwise within 30 minutes, and react in an oil bath at 80°C for 4 hours, After the reaction is complete, NaOH solution is added dropwise until alkaline, then extracted with anhydrous ether, filtered with suction, and distilled under reduced pressure to obtain indole;

[0051] CH 3 CH 2 I was added to the prepared indole in a molar mass ratio of 1: 0.8, dissolved in absolute ethanol and mixed uniformly, refluxed in an oil bath at 80°C for 3 hours, cooled for crystallization, filtered, and purified by recrystallization to obtain an intermediate product; The intermediate product was dissolved in ethanol, 1-nitroso-2,7-dihydroxynaphthalene with the same molar mass as the intermediate product was added, refluxed in an oil...

Embodiment 2-4

[0062] The difference from Example 1 is that the molar ratio of bishydroxyethyl terephthalate to the bisactive spirooxazine material is different, and the other steps are the same as in Example 1, and will not be repeated here.

[0063] Table 1 is the setting of the molar ratio of bishydroxyethyl terephthalate and bisactive spirooxazine materials in Examples 1-4

[0064]

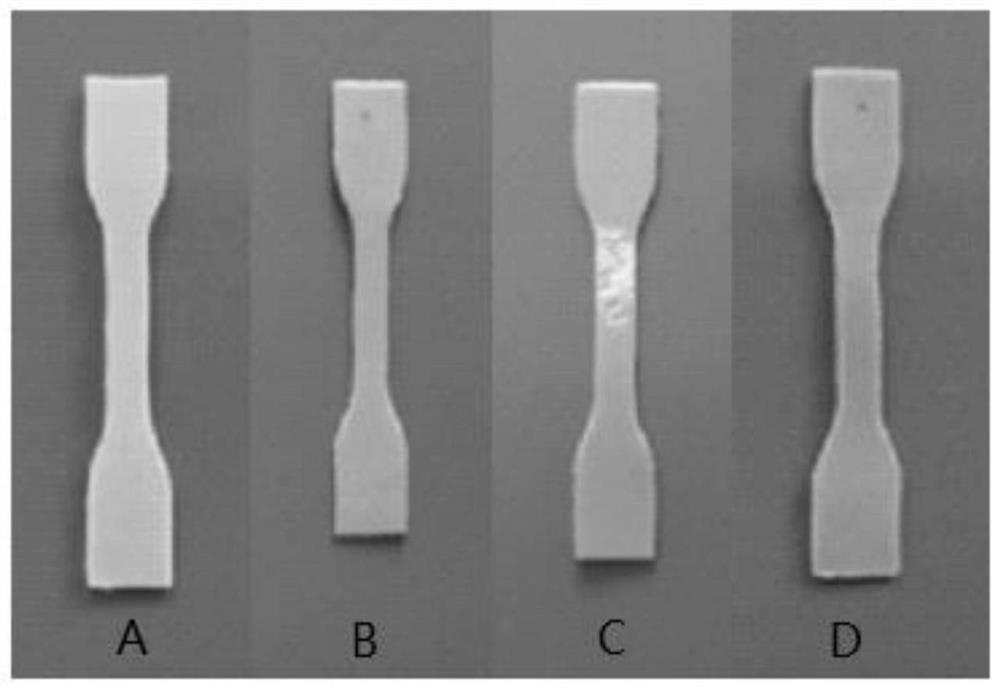

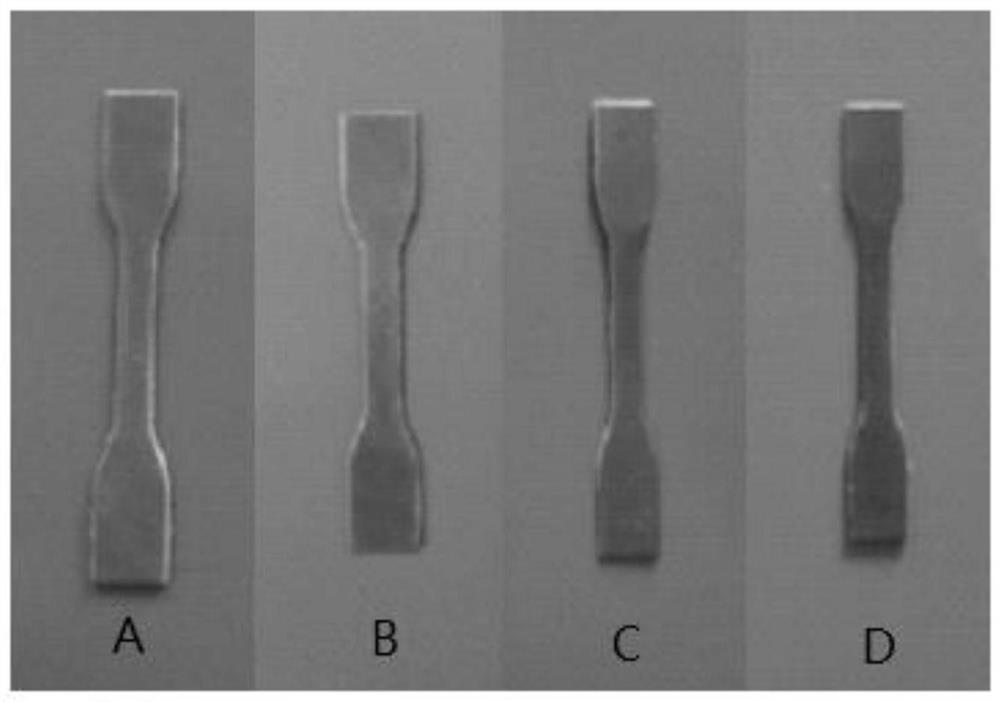

[0065] Embodiment 1-4 is analyzed in conjunction with Table 1: The influence of the molar ratio change of bishydroxyethyl terephthalate and bisactive spirooxazine material on the photochromic polyester material prepared by the present invention is: The molar ratio of hydroxydiethyl ester to the dual-active spirooxazine photochromic material ranges from 1:0.5% to 20%, and different proportions of spirooxazine materials are added to prepare spirooxine with different color depths and color fastnesses. Azinoid photochromic polyester material.

[0066] The higher the ratio of the dual-active spirooxazine mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com