Anti-static MPP power cable tube and preparation method thereof

A cable tube and anti-static technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as poor conductors, achieve improved efficiency, improved dispersion, excellent insulation and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An antistatic MPP power cable tube, prepared from the following raw materials in parts by weight: 60 parts of polypropylene resin, 5 parts of compatibilizer, 5 parts of heat-resistant insulating masterbatch, 10 parts of ultra-high molecular weight polyethylene resin, and flame retardant 3 parts, 1 part of antioxidant, 1 part of coupling agent;

[0035] Wherein, the antistatic MPP power cable tube is prepared by the following steps:

[0036] Step 1: Put the raw materials into a high-speed mixer for physical blending to obtain a modified resin raw material, and extrude the modified resin raw material through a single-screw extruder to obtain a heat-resistant insulating MPP power cable tube;

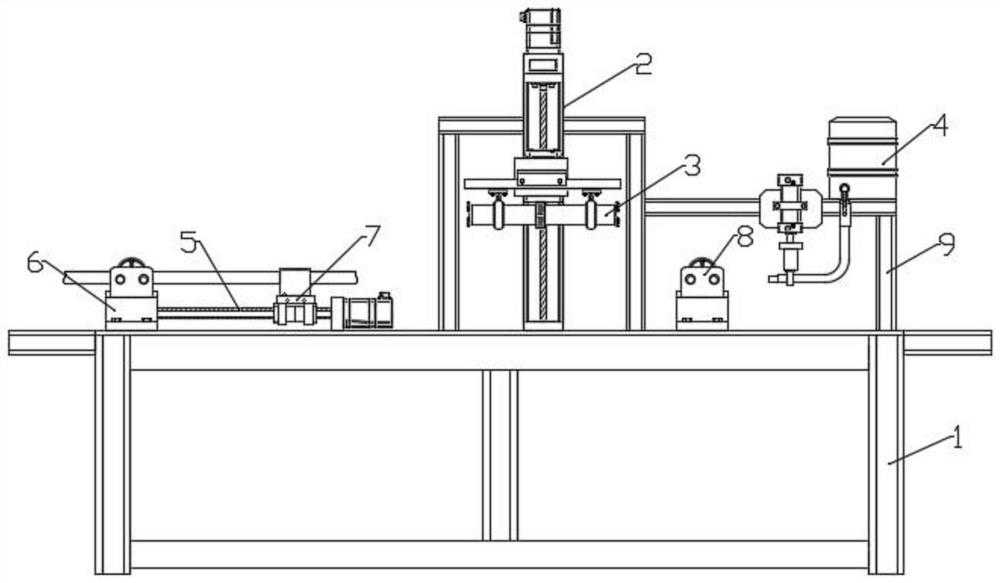

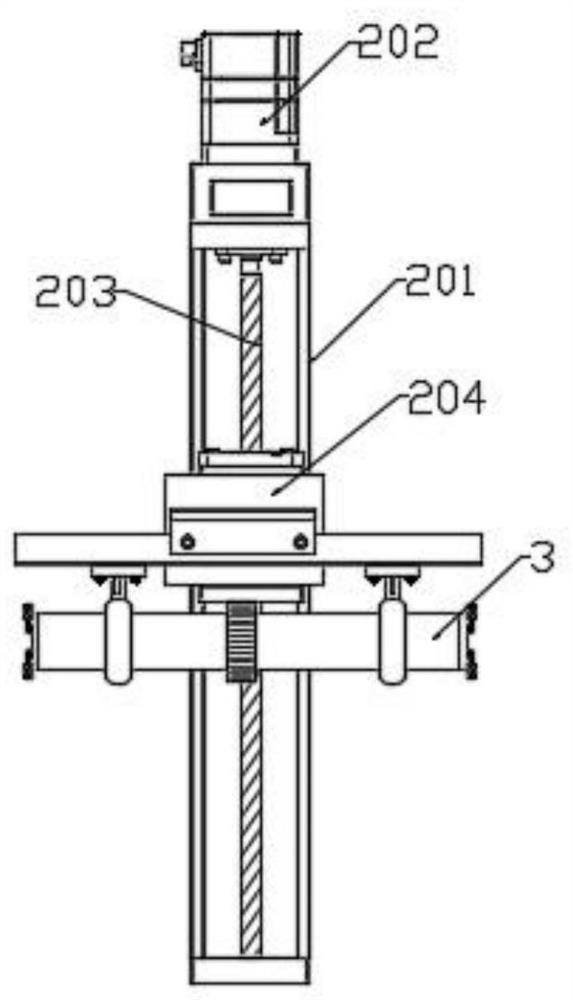

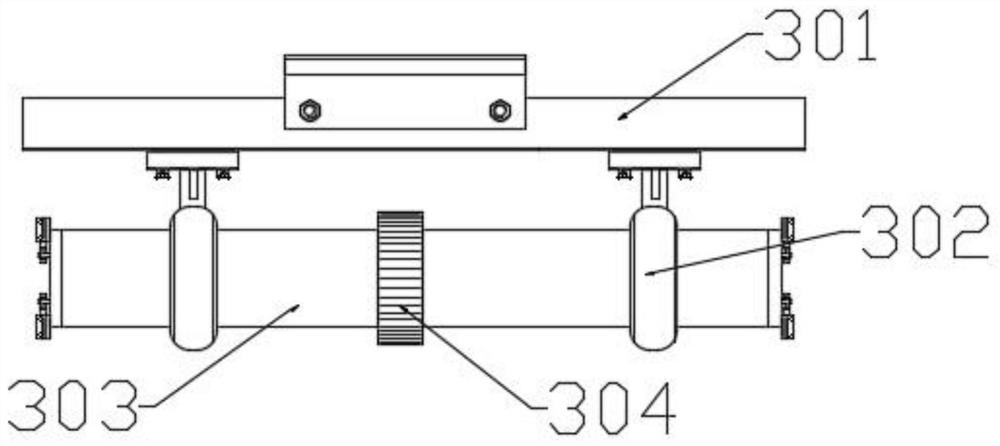

[0037]Step 2: After the heat-resistant insulating MPP power cable tube is cut by the cutting equipment, put it into the first fixing mechanism 6 of the debris cleaning device, and pull the cable tube into the two first clamping blocks 603 on the first fixing mechanism 6, Turn the ha...

Embodiment 2

[0040] An antistatic MPP power cable tube, prepared from the following raw materials in parts by weight: 80 parts of polypropylene resin, 10 parts of compatibilizer, 25 parts of heat-resistant insulating masterbatch, 20 parts of ultra-high molecular weight polyethylene resin, flame retardant 8 parts, 2 parts of antioxidant, 5 parts of coupling agent;

[0041] Wherein, the antistatic MPP power cable tube is prepared by the following steps:

[0042] Step 1: Put the raw materials into a high-speed mixer for physical blending to obtain a modified resin raw material, and extrude the modified resin raw material through a single-screw extruder to obtain a heat-resistant insulating MPP power cable tube;

[0043] Step 2 is the same as in Example 1.

[0044] Specifically, the preparation process of the heat-resistant insulating masterbatch is as follows: Weigh 30 parts of polyamide resin, 25 parts of ethylene-vinyl acetate copolymer, 22 parts of polypropylene resin, 5 parts of antioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com