Preparation method and application of microporous carbon fiber grafted polyaniline/CoNi2S4 composite material

A fiber grafting and composite material technology, applied in the field of electrochemical materials and composite materials, can solve the problems of high energy density and power density, and cannot provide specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

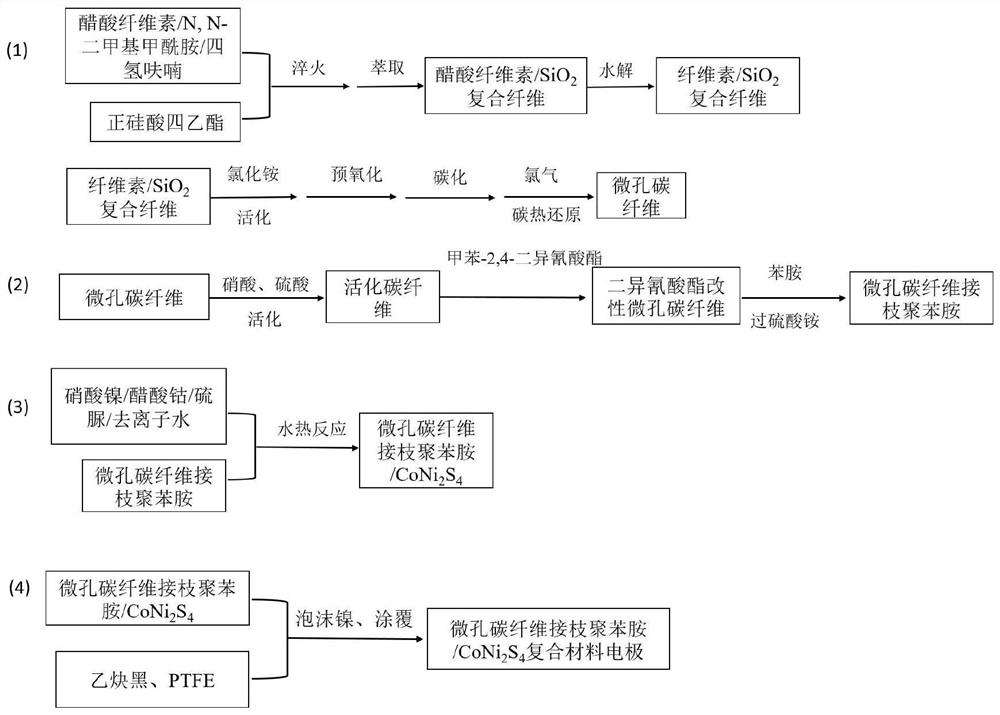

[0030] 1) Preparation of microporous carbon fiber

[0031] 2.8 g of cellulose (CA) was dissolved in a mixed solvent of 30 gn, N'-dimethylformamide and 15 g of tetrahydrofuran, and magnetically stirred at 50 ° C for 5 h, forming a solution. 0.9 g of tetraethyl ester is added dropwise to a solution, and stirring is continued for 2 h to obtain a precursor quenching solution. After the precursor quenching solution was quenched at -20 ° C for 100 min, the soaking of the soaking was removed in distilled water, and the distilled water was changed once every 8 h, and the distillation water was changed 3 times. After washing, dry and get Ca / Sio 2 Composite fiber. CA / SIO 2 The composite fiber soaked in a solution of 0.1 mol / lnaOh ethanol solution for 24 h, converting Ca into cellulose, distilled water washing, dried to give cellulose / SiO 2 Composite fiber. Cellulose / SiO 2 The fiber soaking in the mass concentration is 1% NH 4 In the CL solution, the 80 ° C water bath oscillator wa...

Embodiment 2

[0040] 1) Preparation of microporous carbon fiber

[0041] 3.1 g of cellulose (CA) was dissolved in a mixed solvent of 40 gn, N'-dimethylformamide and 10 g of tetrahydrofuran, 50 ° C magnetic force for 5 h, dissolved, forming a solution. 0.7 g of tetraethyl ester was added dropwise to the solution, and stirring was continued for 2 h to give the precursor quenched solution. After 120 minutes of the precursor quenched solution at -10 ° C, the soaking of the soaking in distilled water was removed, and the distilled water was changed once every 8h, and the distillation water was changed 3 times. After washing, dry and get Ca / Sio 2 Composite fiber. CA / SIO 2 The composite fiber soaked in a solution of 0.1 mol / lnaOh ethanol solution for 24 h, converting Ca into cellulose, distilled water washing, dried to give cellulose / SiO 2 Composite fiber. Cellulose / SiO 2 The fiber soaking in the mass concentration is 0.6% NH 4 In the CL solution, the 80 ° C water bath oscillator was oscilla...

Embodiment 3

[0050] 1) Preparation of microporous carbon fiber

[0051] 3.4 g of cellulose (CA) was dissolved in a mixed solvent of 35 g, N'-dimethylformamide and 15 g of tetrahydrofuran, and magnetically stirred at 50 ° C for 5 h, forming a solution. 0.8 g of tetraethylene titrates were added to the solution and stirred for 2 h, resulting in a precursor quenched solution. After the precursor quenching solution was quenched at -20 ° C for 100 min, the soaking of the soaking was removed in distilled water, and the distilled water was changed once every 8 h, and the distillation water was changed 3 times. After washing, dry and get Ca / Sio 2 Composite fiber. CA / SIO 2 The composite fiber soaked in a solution of 0.1 mol / lnaOh ethanol solution for 24 h, converting Ca into cellulose, distilled water washing, dried to give cellulose / SiO 2 Composite fiber. Cellulose / SiO 2 The fiber soaking in the mass concentration is 0.8% NH 4 In the CL solution, the 80 ° C water bath oscillator was oscillat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com