Preparation method of solid electrolyte, solid electrolyte and all-solid-state battery

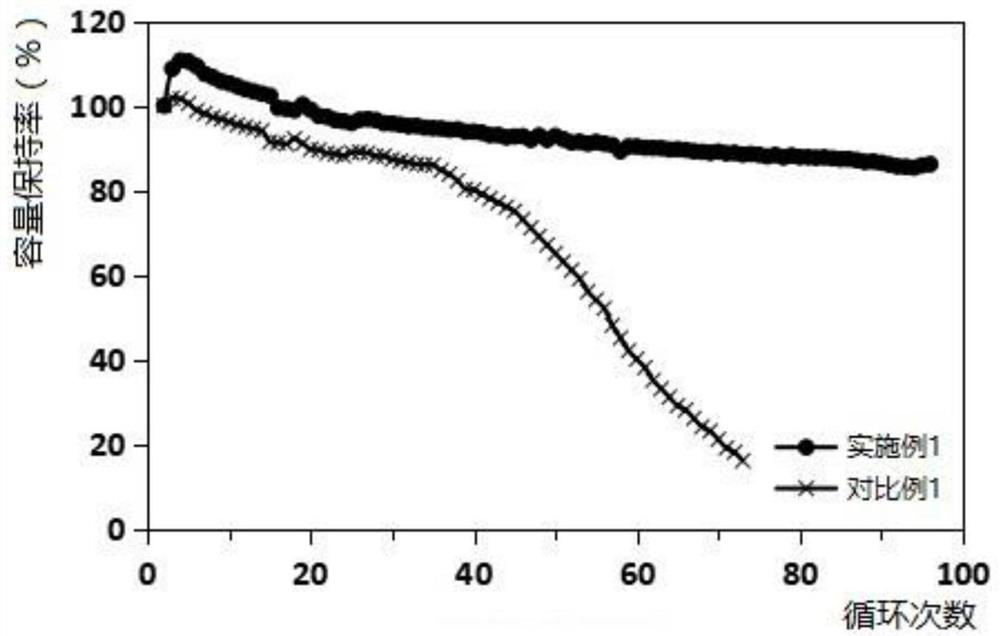

A solid-state electrolyte and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of liquid leakage, large interface impedance of positive and negative electrodes, and poor battery cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The first aspect of the present invention provides a method for preparing a solid electrolyte, comprising the following steps:

[0032] 1) adding the inorganic filler after dissolving the lithium salt, adding the first polymer after the inorganic filler is dispersed, and obtaining the first electrolyte slurry after stirring;

[0033] The first electrolyte slurry includes 10-50% of lithium salt, 10-30% of inorganic filler and 30-80% of the first polymer according to the mass percentage; the solid content of the first electrolyte slurry is 10-40%. ;

[0034] 2) After dissolving the lithium salt, adding a flexible monomer and an initiator, and stirring to obtain a second electrolyte slurry;

[0035] The second electrolyte slurry includes 10-50% lithium salt, 30-80% flexible monomer and 1-3% initiator according to mass percentage; the solid content of the second electrolyte slurry is 10-40%;

[0036] 3) Pour the first electrolyte slurry into the base of the multifunctiona...

Embodiment 1

[0062] The preparation method of the solid-state electrolyte and all-solid-state battery in this embodiment is as follows:

[0063] 1. Preparation of solid electrolyte

[0064] 1) Add 30wt% LiTFSI to DMF, fully dissolve it, add 10wt% LATP, and use an ultrasonic cell pulverizer to fully disperse, add 60wt% polyacrylonitrile (PAN), and stir to obtain the first electrolyte slurry , The solid content of the slurry is 15%.

[0065] 2) Add 30wt% LiTFSI to the solvent, fully dissolve it, add 68.5wt% PEG and 1.5wt% azobisisobutyronitrile (AIBN), stir to obtain the second electrolyte slurry, the slurry solid content is 20%.

[0066] 3) Pour the first electrolyte slurry onto the base of the multifunctional casting machine, and spread a layer of non-woven fabric with a pore size of 6 μm, a porosity of 50%, and a thickness of 8 μm on the surface of the first electrolyte slurry away from the base. Pour the second electrolyte slurry on the non-woven fabric, dry the first electrolyte slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com