Resin composition

A technology of resin composition and resin, applied in the field of resin composition, can solve problems such as insufficient compatibility and insufficient transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0261] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited to these examples.

Synthetic example 1

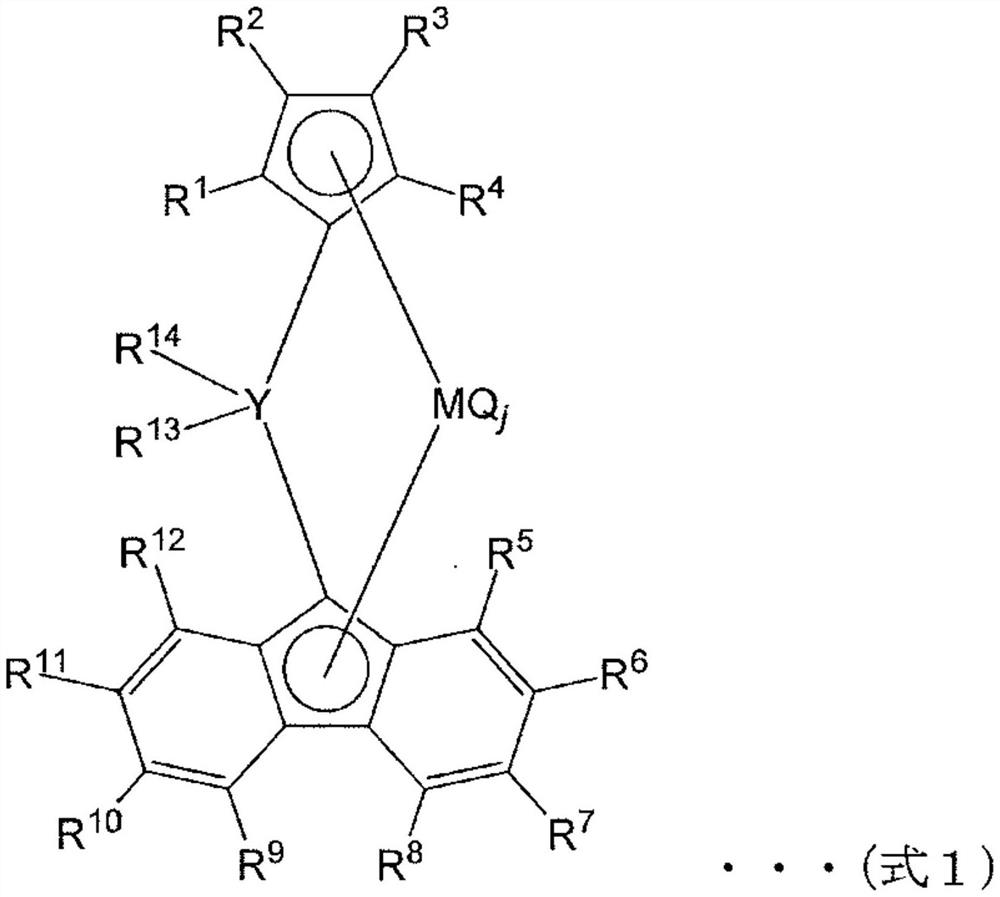

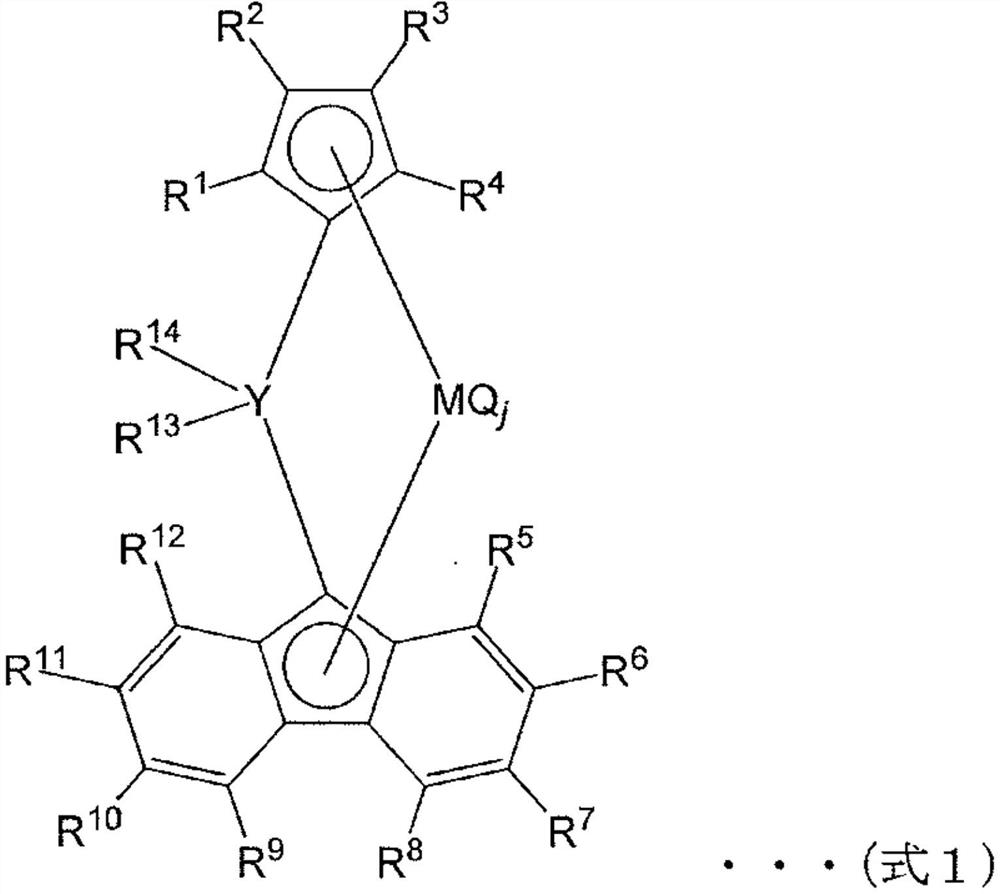

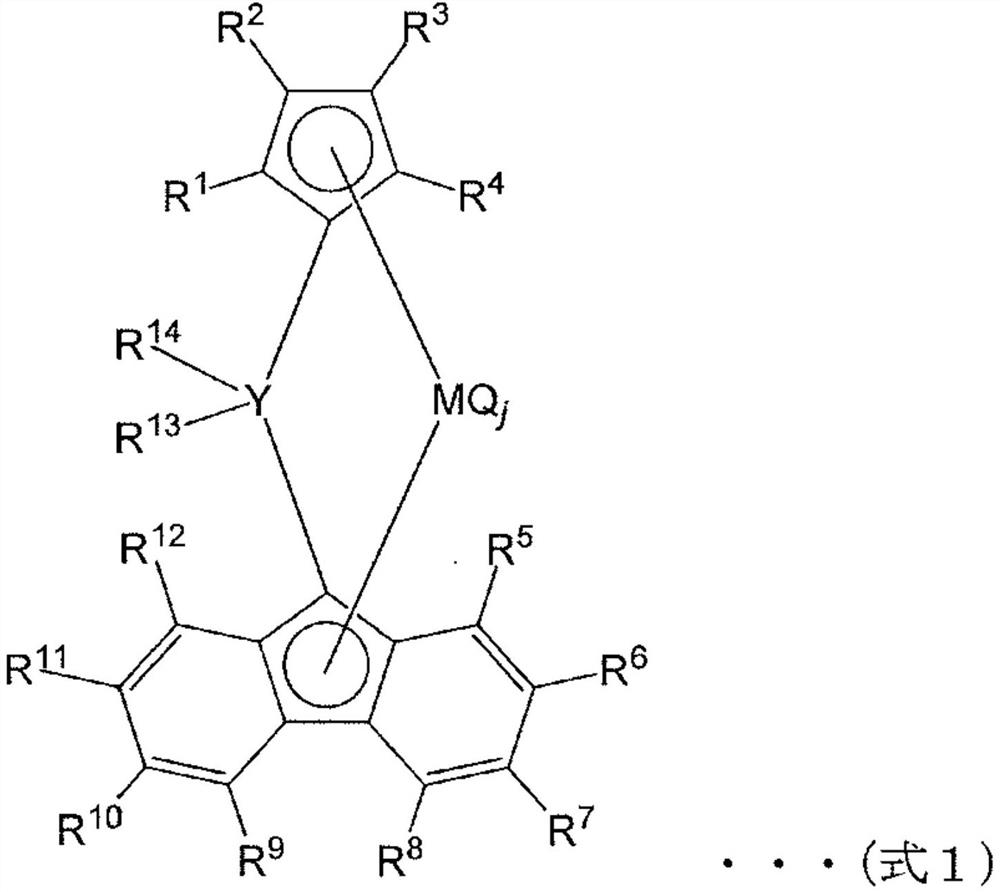

[0262] [Synthetic Example 1] ([methylphenylmethylene (η 5 - cyclopentadienyl) (η 5 Synthesis of -2,7-di-tert-butylfluorenyl)]zirconium dichloride)

[0263] (i) Synthesis of 6-methyl-6-phenylfulvene (6-methyl-6-phenylfulvene)

[0264] Under a nitrogen atmosphere, 7.3 g (101.6 mmol) of lithium cyclopentadiene and 100 mL of dehydrated tetrahydrofuran were added to a 200 mL three-necked flask and stirred. The obtained solution was cooled with an ice bath, and 15.0 g (111.8 mmol) of acetophenone was added dropwise thereto. Afterwards, stirring at room temperature for 20 hours, the resulting solution was quenched with dilute aqueous hydrochloric acid. 100 mL of hexane was added to extract the soluble components, and the obtained organic layer was washed with water and saturated brine, respectively, and dried over anhydrous magnesium sulfate. Then, the solvent was distilled off, and the obtained viscous liquid was separated by column chromatography (hexane), whereby the target pr...

manufacture example 1

[0269] [Production Example 1] (Synthesis of Liquid Ethylene-Propylene Copolymer Using Vanadium Catalyst)

[0270] Add 1 liter of dehydrated and purified hexane to a 2 liter continuous polymerization reactor with stirring blades that has been fully replaced with nitrogen, and feed it continuously at 500 mL / h for 1 hour to adjust to 96 mmol / L Sesquiethyl aluminum chloride (Al(C 2 h 5 ) 1.5 · Cl 1.5 ) hexane solution, and further, as a catalyst, continuously supply VO(OC 2 h 5 ) Cl 2 The hexane solution was continuously supplied with 500 mL / h of hexane. On the other hand, the polymerization liquid was continuously discharged from the upper part of the reactor so that the polymerization liquid in the reactor was constant at 1 liter.

[0271] Next, ethylene gas was supplied in an amount of 35 L / h, propylene gas was supplied in an amount of 35 L / h, and hydrogen gas was supplied in an amount of 80 L / h using a bubbling tube. The copolymerization reaction was performed at 35° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com