Method for preparing magnetic multi-effect adsorbent by using enzymolysis residue dry process

A technology of enzymatic hydrolysis residue and adsorbent, applied in the field of materials, can solve the problems of high cost and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method and application of preparing magnetic multi-effect adsorbent by dry method of enzymolysis residue, the specific steps are as follows:

[0029] Step 1: The corncob enzymolysis residue with a lignin content of 86% is centrifuged and washed with distilled water until neutral, dried, and stored in a dry environment at room temperature for later use.

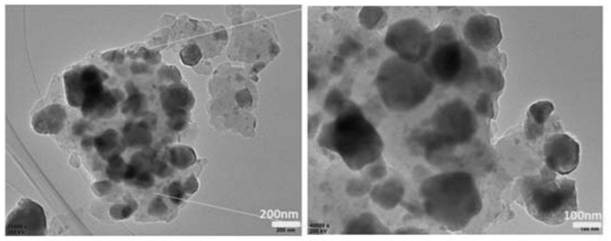

[0030] Step 2: Take the above obtained enzymolysis residue and Co 3 o 4 The nanoparticles were uniformly mixed at a mass ratio of 5:1, and preheated at 100° C. for 3 hours to obtain a pretreated material.

[0031] Step 3: Transfer the treated material to a ball mill jar, and place the ball mill jar in a planetary ball mill, and perform mechanical ball milling at a speed of 80 revolutions / minute and 300 revolutions / minute for 5 hours.

[0032] Step 4: Open the treated ball mill tank, take out the material in the tank and sieve to separate the ball milled zirconium beads, and obtain the magnetic multi-effect adsorbe...

Embodiment 2

[0035] Embodiment 2 (comparative example, do not add magnetic nanoparticles):

[0036] The method and application of preparing multi-effect adsorbent by dry method of enzymolysis residue, the specific steps are as follows:

[0037] Step 1: The corncob enzymolysis residue with a lignin content of 89% is centrifugally washed with distilled water until neutral, dried, and stored in a dry environment at room temperature for later use.

[0038] Step 2: Take the enzymolysis residue obtained above and put it into a ball mill tank, and preheat it at 100° C. for 3 hours to obtain the pretreated material.

[0039] Step 3: Transfer the treated material to a ball mill jar, and place the ball mill jar in a planetary ball mill, and perform mechanical ball milling at a speed of 80 revolutions / minute and 300 revolutions / minute for 5 hours.

[0040] Step 4: Open the treated ball mill tank, take out the material in the tank and sieve to separate the ball milled zirconium beads, and obtain the ...

Embodiment 3

[0044] The method and application of preparing magnetic multi-effect adsorbent by dry method of enzymolysis residue, the specific steps are as follows:

[0045] Step 1: The residue of enzymatic hydrolysis of wheat straw with a lignin content of 81% is centrifuged and washed with distilled water until neutral, dried, and stored in a dry environment at room temperature for later use.

[0046] Step 2: Mix the obtained enzymolysis residue with NiO nanoparticles at a mass ratio of 1:4, and preheat at 80°C for 5 hours to obtain the pretreated material.

[0047] Step 3: Add the pretreated material into the ball milling tank, then place the ball milling tank in a planetary ball mill, and perform mechanical ball milling at a speed of 60 revolutions per minute and 200 revolutions per minute for 4 hours;

[0048] Step 4: Open the treated ball mill tank, take out the material in the tank and sieve to separate the ball milled zirconium beads, and obtain the magnetic multi-effect adsorbent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com