Electrochemical disinfection method based on singlet oxygen

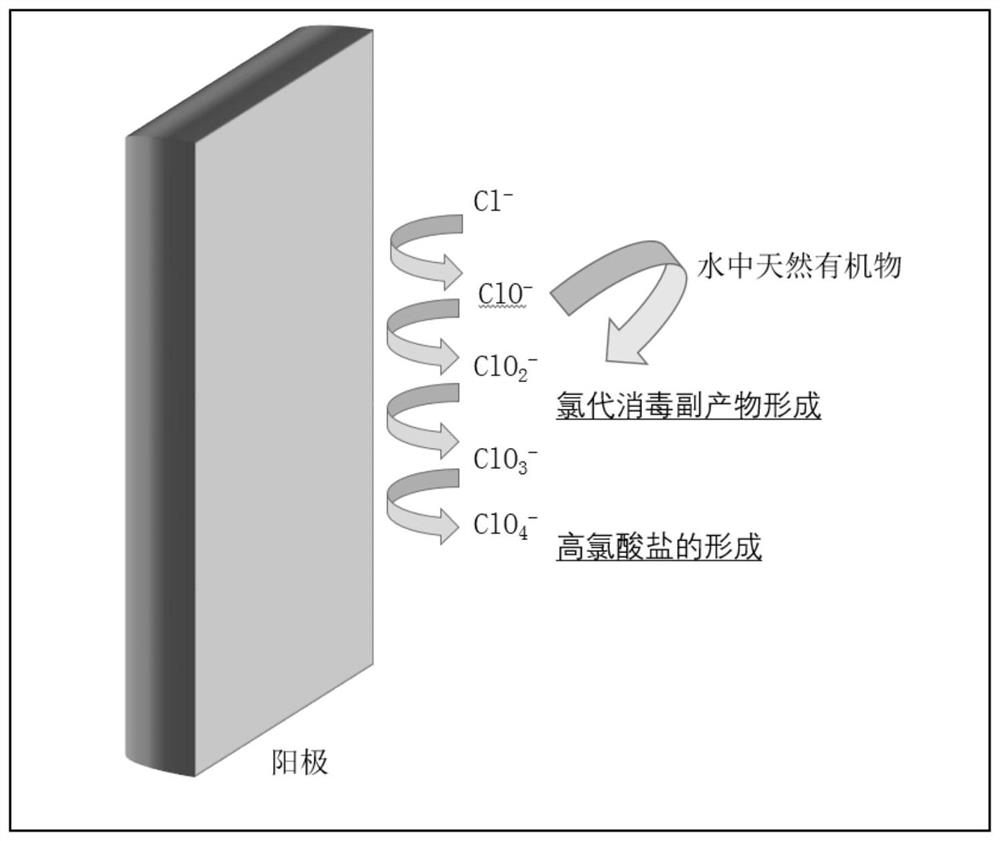

A technology of singlet oxygen and disinfection methods, applied in chemical instruments and methods, sterilization/microkinetic water/sewage treatment, special treatment targets, etc., can solve the problem of easy generation of chlorinated organic disinfection by-products and inorganic disinfection of chlorate radicals by-products etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

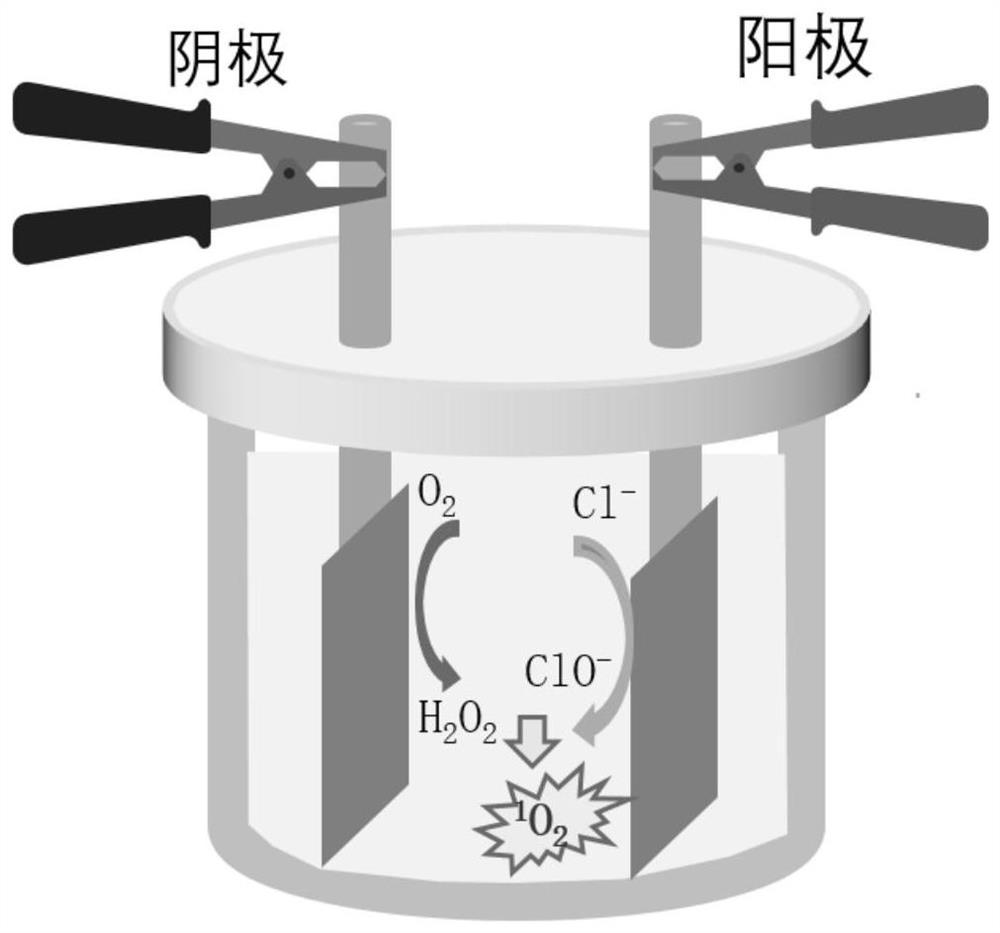

[0033] Embodiment 1: This embodiment is based on the electrochemical disinfection method of singlet oxygen, which is carried out according to the following steps:

[0034] Using the electrode that generates hypochlorous acid in situ as the anode, the hypochlorous acid and hydrogen peroxide generated by the sequencing batch electrochemical reaction are used to generate singlet oxygen, which is used to kill microorganisms in the water;

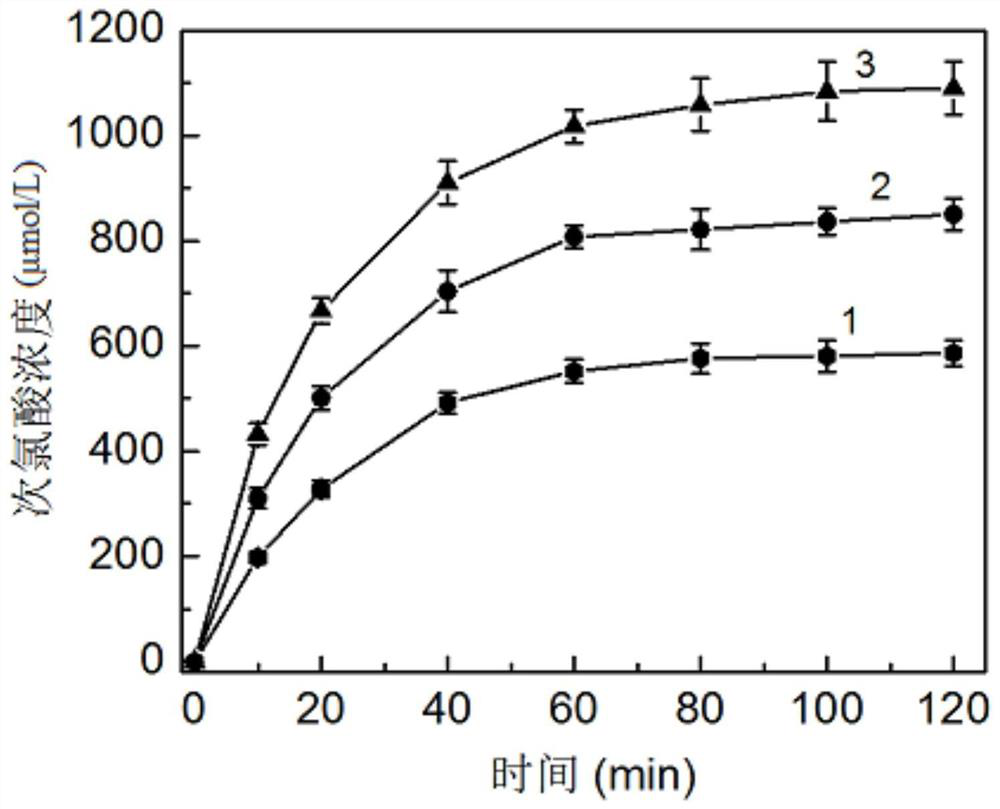

[0035] When the cathode is graphite felt electrode, stainless steel or titanium; set the anode and cathode in the electrochemical reactor, and the distance between the two electrodes is 1cm~20cm, and the volume ratio of the area of the electrode to the water to be treated is 1cm 2 : (10~200)mL, add the water to be treated into the electrochemical reactor, aerate air or oxygen into the electrochemical reactor, the reaction temperature is 3℃~30℃, and the aeration rate is 60mL / min~200mL / min, the voltage is 2V~30V and the current density is 2.5mA...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment is different from Embodiment 1 in that the anode is a platinum-titanium electrode, a boron-doped diamond film electrode or an iridium-ruthenium-titanium oxide electrode; the gas diffusion electrode is made of carbon nanotubes. , One or several modified graphite electrodes of polytetrafluoroethylene and carbon black. Others are the same as the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the described iridium ruthenium titanium oxide electrode is specifically carried out according to the following steps:

[0050] ①. Put the titanium sheet in the mixed liquid containing hydrofluoric acid and nitric acid, and ultrasonically treat it for 30min-180min to obtain the titanium sheet with the oxide film removed; the concentration of hydrofluoric acid in the mixed liquid containing hydrofluoric acid and nitric acid It is 0.1mol / L~1mol / L, and the molar ratio of hydrofluoric acid and nitric acid is (0.5~2): 1; ②, take the titanium sheet that removes the oxide film as the cathode and the anode respectively, and carry out cathode ruthenium plating treatment, with the concentration of Be that the ruthenium trichloride solution of 1mmol / L~20mmol / L is electrolyte, under the condition that temperature is 5 ℃~30 ℃ and voltage is -3V~-1V, electroplating 5min~30min, after electroplating, take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com