Cement-based anti-corrosion spraying material applied to steel chimney and preparation method of cement-based anti-corrosion spraying material

An anti-corrosion spraying, cement-based technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as sudden reduction in service time, cracking, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

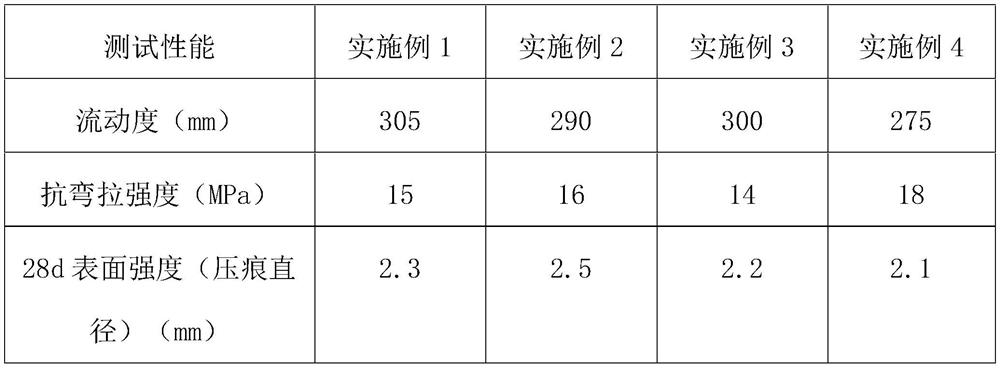

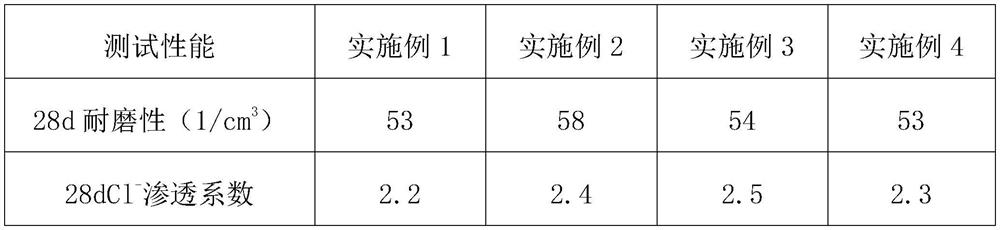

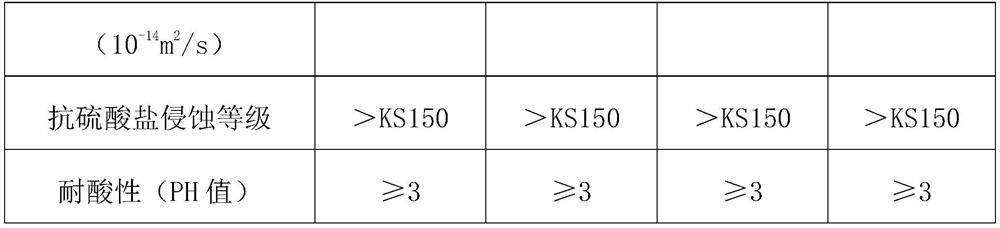

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned cement-based anticorrosion spraying material applied to steel chimneys comprises the following steps:

[0039] The step of preparing the premix: pour the cement, silica fume, powdered coal, quartz powder and quartz sand into the mixer and stir for 1-10 minutes, and mix evenly to prepare the premix;

[0040] Steps for preparing the finished product: add 60%-80% formula quantity of water and water reducer to the premix, stir for 2-20min, then add formula quantity of tackifier, toughener, anti-corrosion agent, remaining water and The admixture is continuously stirred for 2-10 minutes to obtain a cement-based anti-corrosion spraying material applied to a steel chimney.

Embodiment 1

[0042] A cement-based anti-corrosion spraying material applied to steel chimneys, comprising the following components in parts by weight:

[0043] 50 parts of cement, 15 parts of silica fume, 8 parts of fly ash, 5 parts of quartz powder, 180 parts of quartz sand, 0.5 parts of tackifier, 15 parts of toughening agent, 8 parts of corrosion inhibitor, 5 parts of water reducing agent, 35 parts of water share.

[0044] The cement is P.O52.5 ordinary Portland cement. The specific surface area of silica fume is 17000m 2 / kg, SiO in silica fume 2 The mass content of silica fume 28d is 96%, and the activity index of silica fume 28d is 115%. Fly ash is superfine fly ash, and the specific surface area of fly ash is 1710m 2 / kg, the loss on ignition of fly ash is 2.6%, and the 28d activity index of fly ash is 96%. SiO in quartz powder 2 The mass content of the quartz powder is 95%, and the specific surface area of the quartz powder is 600m 2 / kg; the fineness modulus of quartz...

Embodiment 2

[0049] A cement-based anti-corrosion spraying material applied to steel chimneys, comprising the following components in parts by weight:

[0050] 100 parts of cement, 30 parts of silica fume, 22 parts of fly ash, 20 parts of quartz powder, 100 parts of quartz sand, 0.1 part of tackifier, 1 part of toughening agent, 0.5 part of anti-corrosion agent, 0.5 part of water reducer, 10 parts of water share.

[0051] The cement is P.O52.5 ordinary Portland cement. The specific surface area of silica fume is 18000m 2 / kg, SiO in silica fume 2 The mass content of silica fume 28d is 97%, and the activity index of silica fume 28d is 120%. The fly ash is superfine fly ash, and the specific surface area of the fly ash is 1700m 2 / kg, the loss on ignition of fly ash is 2.8%, and the 28d activity index of fly ash is 98%. SiO in quartz powder 2 The mass content of the quartz powder is 97%, and the specific surface area of the quartz powder is 650m 2 / kg; the fineness modulus of qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com