Blast furnace gas desulfurization process

A technology for blast furnace gas and desulfurization process, which is applied in the petroleum industry, combustible gas purification, removal of gas pollutants, etc., and can solve problems such as reducing the calorific value of gas and corrosion of pipeline equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

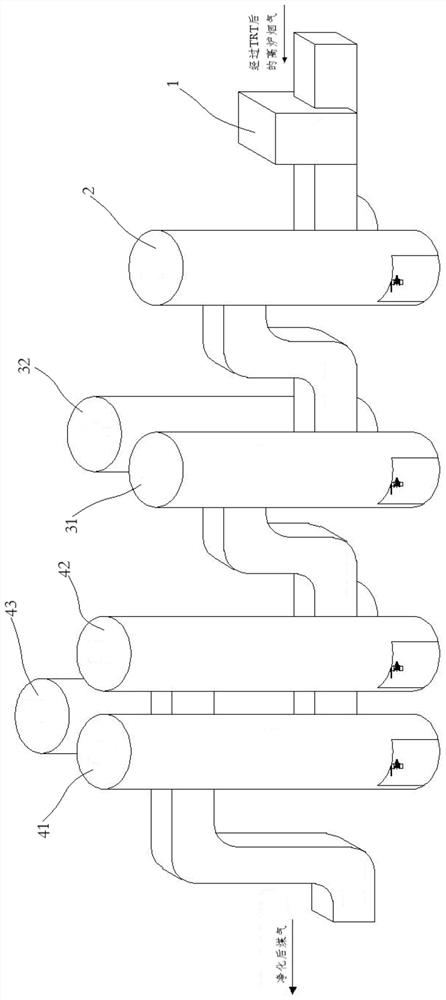

[0059] figure 1 It is a structural schematic diagram of the equipment used in Examples 1-2.

[0060] (1) The blast furnace gas after TRT (the parameters of the blast furnace gas after TRT are shown in Table 1) is heated to 80° C. through the heating device 1 to form blast furnace gas to be treated after TRT. The heating device 1 is an air-to-air heat exchanger.

[0061] (2) The blast furnace gas to be treated enters the pretreatment reactor 2 from the bottom of the pretreatment reactor 2 . The pretreatment reactor 2 is a fixed bed reaction tower. The pretreatment reactor 2 is provided with a plurality of pretreatment agent chambers, and the pretreatment chambers are filled with pretreatment agents. The blast furnace gas to be treated entering from the bottom of the pretreatment reactor 2 contacts and reacts with the pretreatment agent from bottom to top, so that the hydrogen chloride and part of H in the blast furnace gas to be treated 2 S and other acid corrosion products...

Embodiment 3

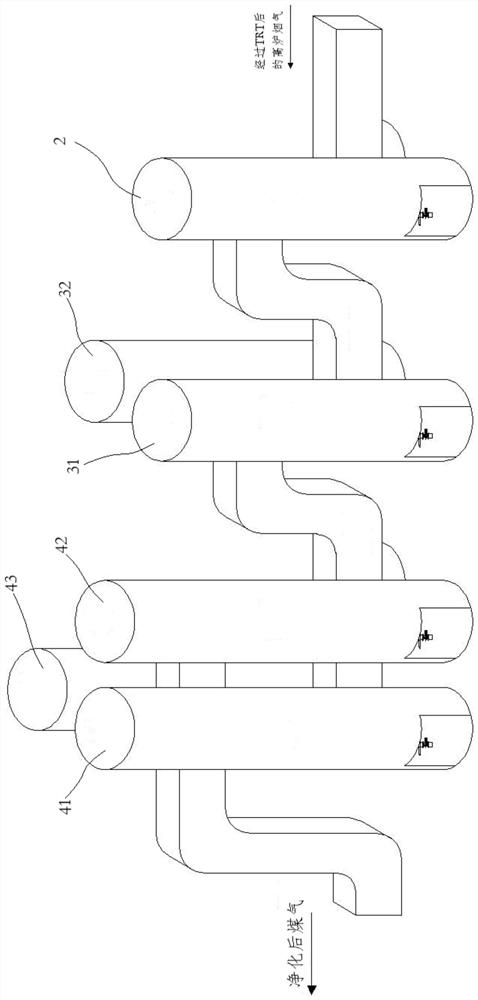

[0067] figure 2 It is a schematic structural diagram of the equipment used in this embodiment. Except step (1) as described below, all the other are the same as embodiment 1.

[0068] (1) The temperature of the blast furnace gas after TRT is 70-100°C to meet the service conditions without going through the heating device 1 to raise the temperature. The blast furnace gas after TRT is the blast furnace gas to be treated after TRT. The detailed parameters of blast furnace flue gas after TRT are shown in Table 1.

[0069] The above equipment has been in continuous operation for more than 3 months, and the outlet is continuously monitored by gas chromatography. The total sulfur concentration at the outlet is stable, and there is no obvious corrosion in the pipeline of subsequent equipment.

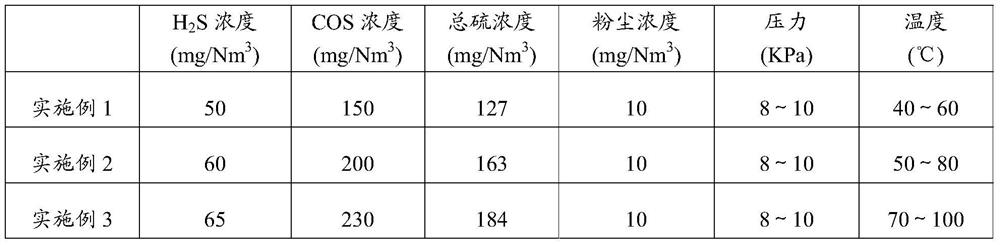

[0070] Table 1

[0071]

[0072] Table 2

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com