Restoration method for ion type rare earth ore non-ammonium system ore leaching site

A technology of ion-type rare earth ore and rare earth tailings, which is applied in the field of resources and environment, and can solve problems such as nutrient imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The available calcium of the ionic rare earth ore is 274.53 mg / kg, the available magnesium is 25.96 mg / kg, and the ratio of calcium to magnesium is 10.57.

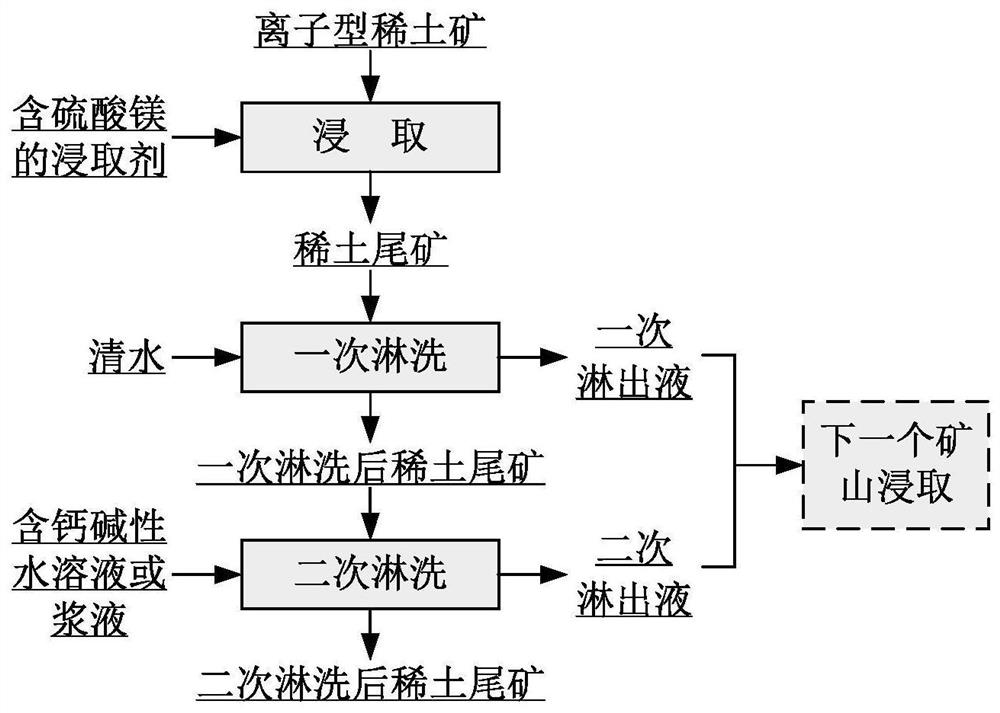

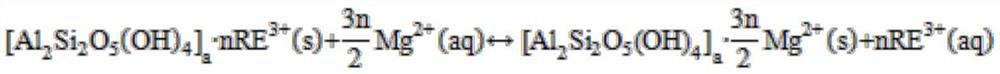

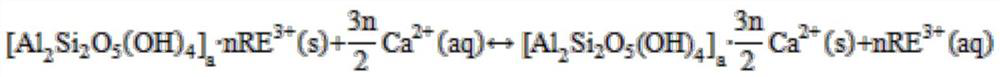

[0056] The ion-type rare earth ore is leached with a leaching agent containing magnesium sulfate. The leaching agent may also contain one or more of calcium chloride, magnesium chloride, and ferrous sulfate. The cation concentration is 0.20mol / L. Solid ratio is 1m 3 / t; wash with clean water once, and the liquid-solid ratio is 0.2m 3 / t, the pH value of the eluent is 7.51; calcium hydroxide solution is used for secondary eluting, and the liquid-solid ratio of the rare earth tailings after the first eluting is 0.4m 3 / t, the molar concentration of calcium hydroxide is 0.02mol / L, and the pH value is 12.53. The leachate obtained from the two washings is returned to be used for leaching in the next ion-type rare earth mine. See Table 1 for the specific effect. It can be seen that the pH value of the rare earth tailin...

Embodiment 2

[0060] The available calcium of the ionic rare earth ore is 274.53 mg / kg, the available magnesium is 25.96 mg / kg, and the ratio of calcium to magnesium is 10.57.

[0061] The ionic rare earth ore is leached with a leaching agent containing magnesium sulfate, the cation concentration is 0.20mol / L, and the liquid-solid ratio is 1m 3 / t, the pH value of the rare earth tailings obtained after leaching is 3.41; wash with clean water once, and the liquid-solid ratio is 0.2m 3 / t, the pH value of the eluent is 7.51; calcium hydroxide solution is used for secondary eluting, and the liquid-solid ratio of the rare earth tailings after the first eluting is 0.4m 3 / t, the molar concentration of calcium hydroxide is 0.02mol / L, and the pH value is 12.53. The leachate obtained from the two washings is returned to be used for leaching in the next ion-type rare earth mine. See Table 2 for the specific effect. It can be seen that increasing the amount of water for one leaching helps to improv...

Embodiment 3

[0065] The available calcium of the ionic rare earth ore is 274.53 mg / kg, the available magnesium is 25.96 mg / kg, and the ratio of calcium to magnesium is 10.57.

[0066] Magnesium sulfate leaching agent is used to leach ionic rare earth ore, the cation concentration is 0.20mol / L, and the liquid-solid ratio is 1m 3 / t, the pH value of the rare earth tailings obtained after leaching is 3.41; wash with clean water once, and the liquid-solid ratio is 0.2m 3 / t, the pH value of the leaching agent is 4.33, and the pH value of the rare earth tailings after the first leaching is 7.51; the calcium hydroxide solution is used for secondary leaching, and the liquid-solid ratio of the rare earth tailings after the first leaching is changed, Referring to Table 3, the molar concentration of calcium hydroxide in the calcium hydroxide solution is 0.02mol / L, and the pH value is 12.53. The leachate obtained from the two washings is returned to be used for leaching in the next ion-type rare ear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com