UNS N10003 alloy surface carburizing method

A surface carburizing and alloying technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of not providing carburizing process parameters HastelloyN alloy structure and mechanical properties data and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

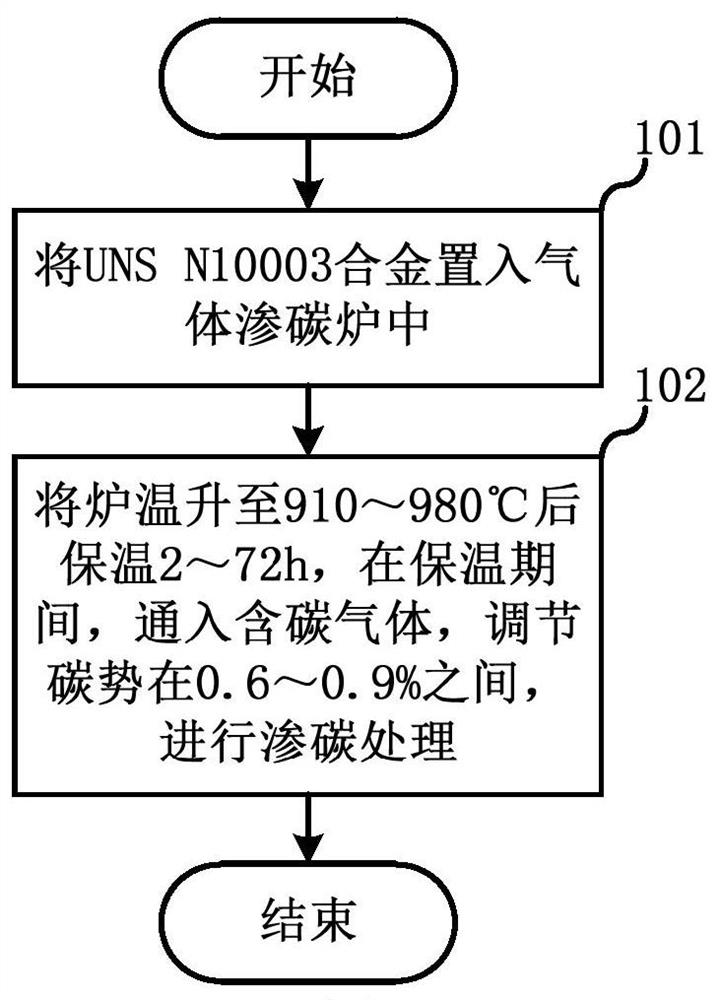

Method used

Image

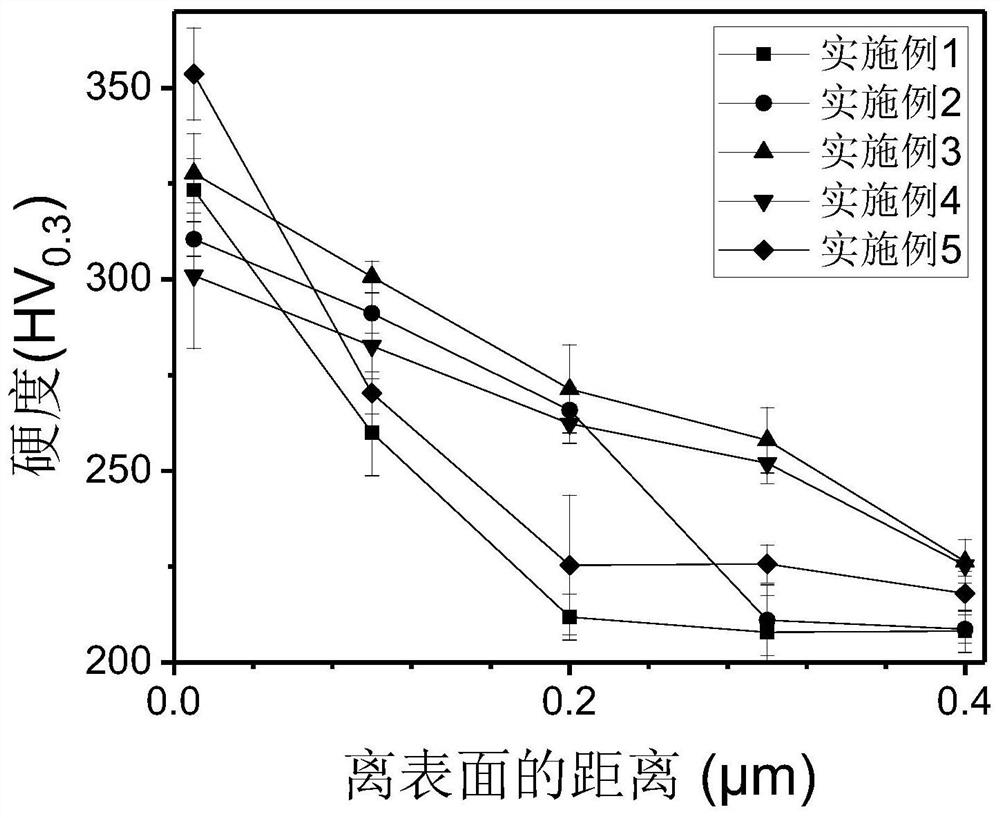

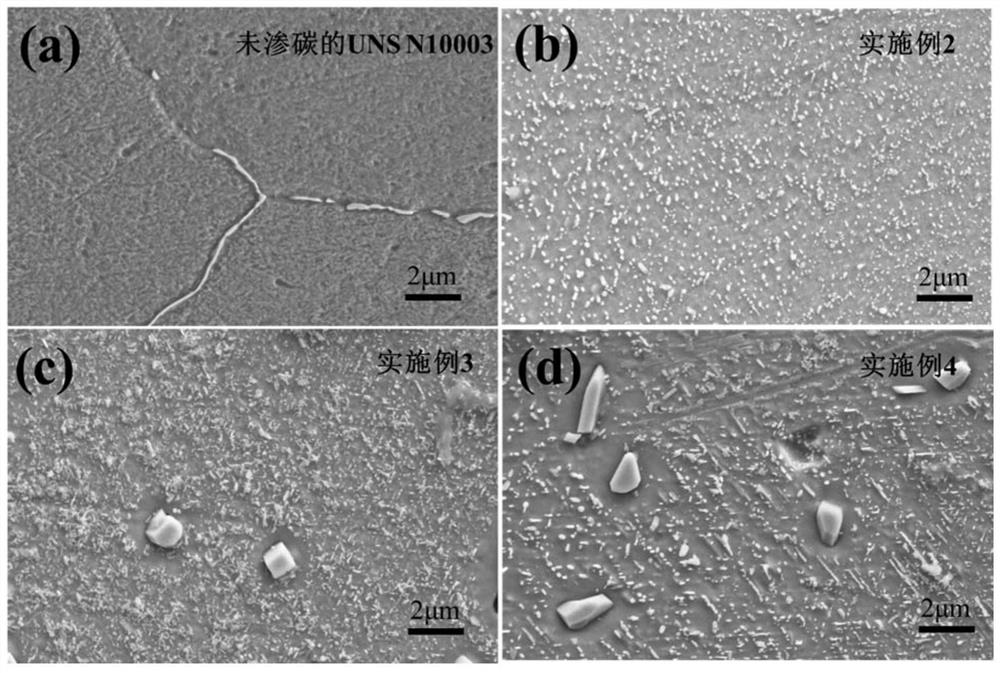

Examples

Embodiment Construction

[0031] In the following description, many technical details are proposed in order to enable readers to better understand the application. However, those skilled in the art can understand that the technical solutions claimed in this application can be realized even without these technical details and various changes and modifications based on the following implementation modes.

[0032] Explanation of some concepts:

[0033] Carbon potential: carbon potential, carbon potential is the same as water potential and electric potential, the potential difference determines the trend of material flow, and the carbon potential difference determines the direction of carbon diffusion. When freely diffusing, carbon always moves from a place with a high carbon potential to a carbon potential Diffusion in low places.

[0034] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manner of the present application will be furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com