Full-automatic vertical hot mixing and air cooling blanking system and method for feed

A fully automatic, hot-mixing technology, applied in feed, hearth furnace, dry solid materials, etc., can solve the problems of nutrient damage of raw materials, reduction of finished feed completion, adverse health reactions of animals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

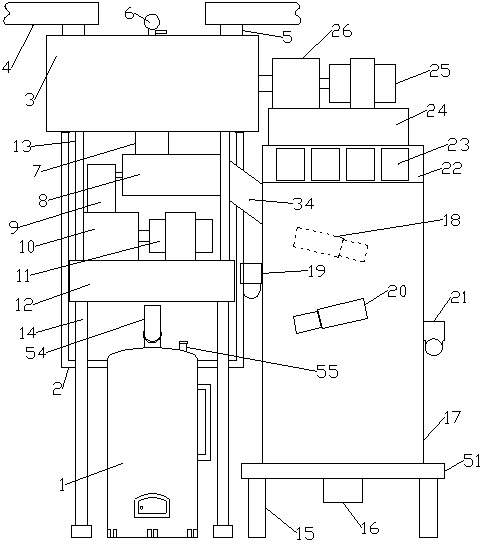

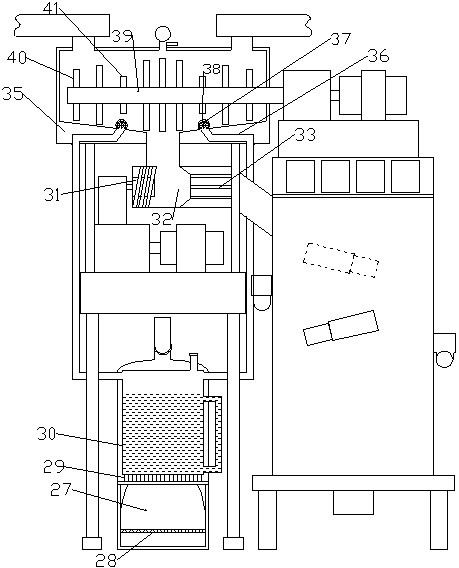

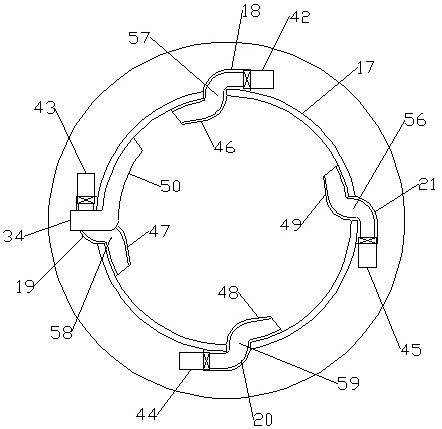

[0021] Such as figure 1 , 2 , As shown in 3 and 4, a fully automatic vertical hot-mixing air-cooled blanking system for feed includes a steam manufacturing device, the steam manufacturing device is connected with the thermal mixing device, and the thermal mixing device is connected with the granulation device , the granulation device is connected with the wind speed cold blanking device, the top of the hot mixing device is connected with the feeding mixing cylinder 4, and the bottom of the wind speed cold blanking device is connected with a discharge packaging material inlet 16. Described steam production device comprises steam production furnace 1, and thermal mixing device comprises mixing bin 3, and granulation device comprises granulator 8, and wind speed cold blanking device comprises wind speed cold drop material barrel 17, and the top of steam production furnace 1 passes steam The conveying pipe 2 communicates with the bottom of the mixing bin 3, and a blanking limit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com