Method for preparing phase-change-adjustable emulsion gel type fat substitute and application

A technology for fat substitutes and emulsion gels, which is applied in the field of preparation of phase change-adjustable emulsion gel fat substitutes, which can solve product taste and health problems, reduce the amount of oil-soluble small-molecule gels used, limit oil Gel application range and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for preparing an emulsion gel type fat substitute with adjustable phase transition, comprising the steps of:

[0060] (1) Weighing 10 parts of ethyl cellulose and 2 parts of glyceryl monostearate were dissolved in 88 parts of soybean oil at 150°C, stirred for 10 minutes and then placed in a water bath at 70°C to obtain an oil solution;

[0061] (2) Dissolve 10 parts of gelatin in 90 parts of hot water at 70°C and stir for 10 minutes to obtain an aqueous solution;

[0062] (3) Mix the oil solution of step (1) and the aqueous solution of step (2) according to the mass ratio of 4:6, and use a high-speed homogenizer to emulsify the mixed solution for 2 minutes at a rate of 10000rpm to obtain an emulsion; The emulsion is placed at room temperature and stirred at a low speed of 400 rpm until the system gels for emulsification to obtain an oil-in-water emulsion gel type fat substitute.

Embodiment 2

[0064] Adjust the mass ratio of the oil solution to the aqueous solution in step (3) of Example 1 to 6:4, and keep the other same as Example 1 to obtain a water-in-oil emulsion gel fat substitute.

Embodiment 3

[0066] Adjust the mass ratio of oil solution and aqueous solution in embodiment 1 step (3) to be 44:56, other and embodiment 1 keep consistent, obtain semi-double continuous type emulsion gel type (contain oil-in-water type emulsion and water-in-oil type emulsion simultaneously ) fat substitute.

[0067] The emulsion gel type fat substitute that embodiment 1~3 obtains is carried out performance test, and test result is as follows:

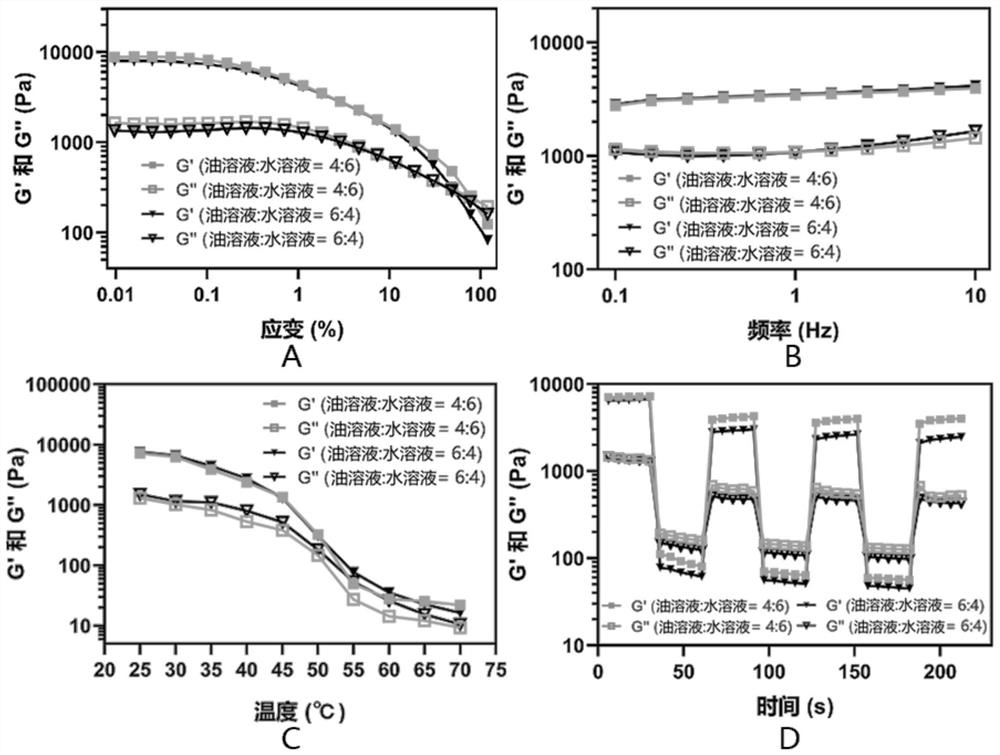

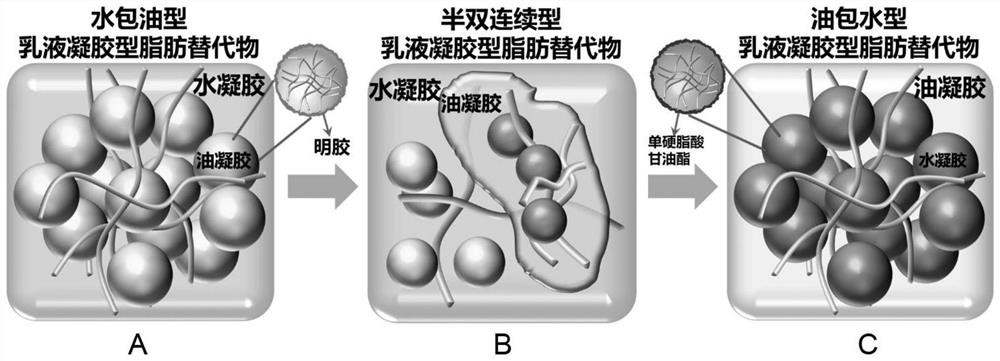

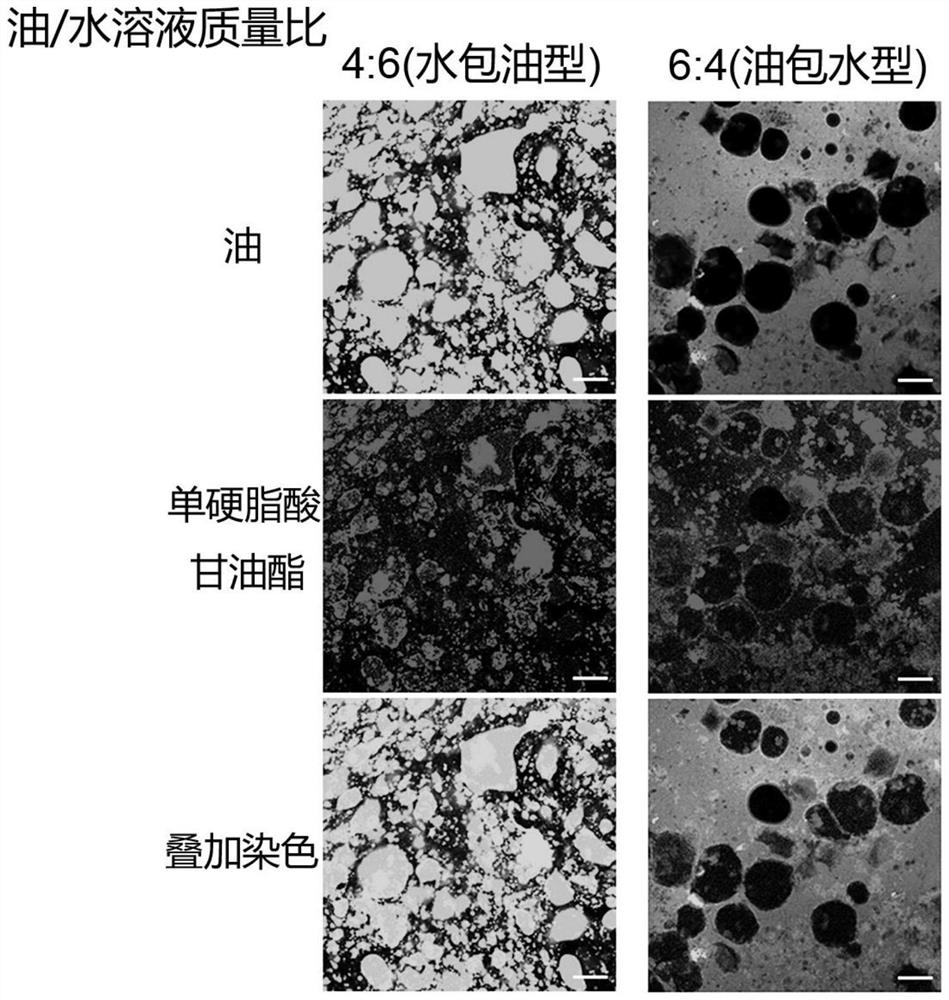

[0068] figure 1 It is the rheological data of two kinds of emulsion gel type fat substitutes of embodiment 1 and 2. From figure 1 It can be seen that: in the strain scanning, the elastic modulus of the two emulsion gel fat substitutes is basically the same, but the oil solution / water solution is 6:4 emulsion gel fat substitute (water-in-oil type) The viscous modulus is slightly lower, indicating that the fluidity of the water-in-oil emulsion-gel fat substitute is slightly better. The elastic modulus and viscous modulus of the two emulsion-gel fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Viscosity modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com