Injectable silk fibroin/nano-hydroxyapatite composite hydrogel and preparation method thereof

A nano-hydroxyapatite and hydroxyapatite technology, applied in pharmaceutical formulations, medical science, prostheses, etc., can solve the limitations of popularization, application and performance, difficulty in storage and transportation of hydrogel raw materials, interface bonding strength, mixing It is difficult to guarantee the scale and uniformity, so as to achieve the effect of easy industrialization and popularization and application, efficient and fast preparation method, and meet the needs of clinical application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Select 0.05% Na 2 CO 3 20g silkworm cocoons were degummed with 1L of the solution, washed and dried to obtain silk fibroin fibers.

[0048] (2) Dissolve 5 g of silk fibroin fibers with 50 ml of calcium chloride / ethanol / water (molar ratio 1:2:8) ternary system solution at 70°C to obtain 10% (w / v) silk fibroin fibers. protein mixture solution.

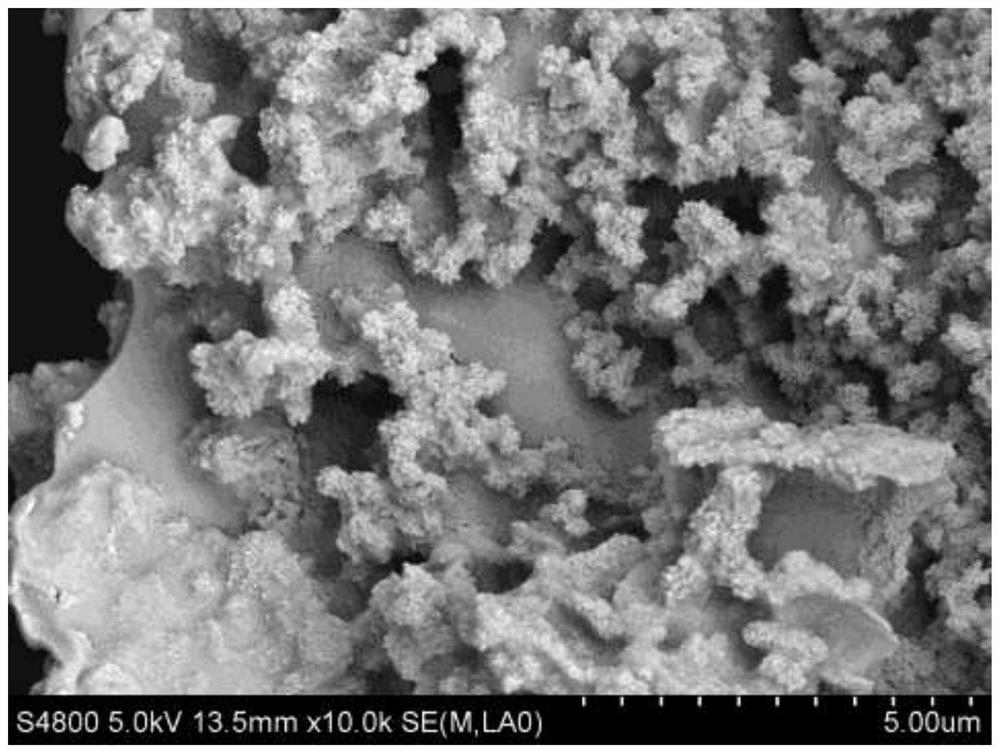

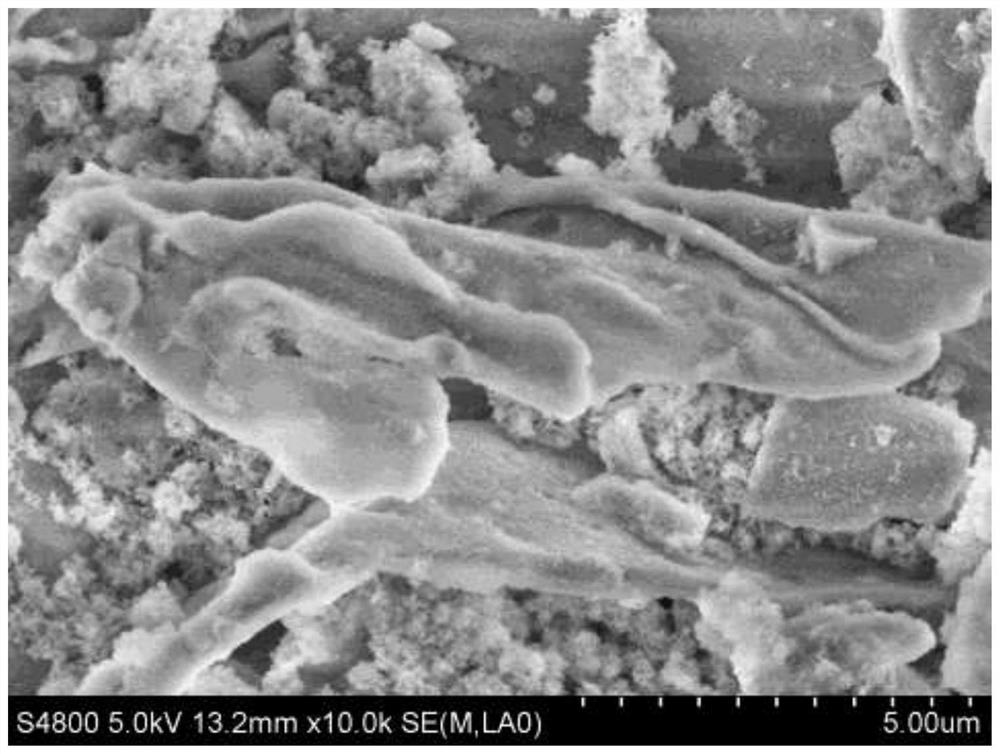

[0049] (3) At 37°C, gradually add 10.0 g of ammonium dihydrogen phosphate to the silk fibroin mixed solution obtained in step (2) according to the molar ratio of calcium: phosphorus of 10:6, and use 2M ammonia water to adjust the pH value to 10.0, stirring and reacting for 6 hours; after the reaction, the silk fibroin / nano-hydroxyapatite composite solution was obtained by dialysis.

[0050] (4) The silk fibroin / nano-hydroxyapatite composite solution obtained in step (3) is induced with ultrasonic power of 250 watts and the ultrasonic power ratio is 90% for 1 min to obtain injectable silk fibroin / nano-hydroxyapatite Apatite...

Embodiment 2

[0052] (1) Select 0.05% Na 2 CO 3 20g silkworm cocoons were degummed with 1L of the solution, washed and dried to obtain silk fibroin fibers.

[0053] (2) Dissolve 15g of silk fibroin fiber with 50ml of calcium chloride / ethanol / water (molar ratio: 1:2:8) ternary system solution at 70°C to obtain 15% (w / v) silk protein mixture solution.

[0054] (3) At 60°C, gradually add 15.0 g of diammonium hydrogen phosphate to the silk fibroin mixed solution obtained in step (2) at a molar ratio of calcium: phosphorus of 10:6, and use 2M sodium hydroxide to adjust the pH value to 9.0, stirred for 4 hours; after the reaction, the silk fibroin / nano-hydroxyapatite composite solution was obtained by dialysis.

[0055] (4) The silk fibroin / nano-hydroxyapatite composite solution obtained in step (3) is induced with ultrasonic power of 250 watts and the ultrasonic power ratio is 30% for 2 minutes to obtain injectable silk fibroin / nano-hydroxyapatite Apatite composite hydrogel; the silk fibroin...

Embodiment 3

[0057] (1) Select 0.05% Na 2 CO 3 The solution degummed 20 g silkworm cocoons, washed and dried to obtain silk fibroin fibers.

[0058] (2) Dissolve 5g of silk fibroin fiber with 100ml of calcium chloride / ethanol / water (molar ratio is 1:2:8) ternary system solution at 75°C to obtain 5% (w / v) silk fibroin protein mixture solution.

[0059] (3) At 60°C, gradually add 30 g of diammonium hydrogen phosphate to the silk fibroin mixed solution obtained in step (2) according to the molar ratio of calcium: phosphorus of 10:6, and adjust the pH value to 10 with ammonia water, The reaction was stirred for 2 hours; after the reaction, the silk fibroin / nano hydroxyapatite composite solution was obtained by dialysis.

[0060] (4) The silk fibroin / nanometer hydroxyapatite composite solution obtained in step (3) is induced with ultrasonic power of 250 watts and an ultrasonic power ratio of 70% for 0.5 min to obtain injectable silk fibroin / nano Hydroxyapatite composite hydrogel; the silk f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com