Production process for extracting pea protein isolate with high gel property through glycosylation method

A technology of pea protein isolate and production process, which is applied in the direction of plant protein processing, protein composition of vegetable seeds, protein food ingredients, etc. problems, to achieve the effect of improving stability and certainty, improving gel characteristics, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

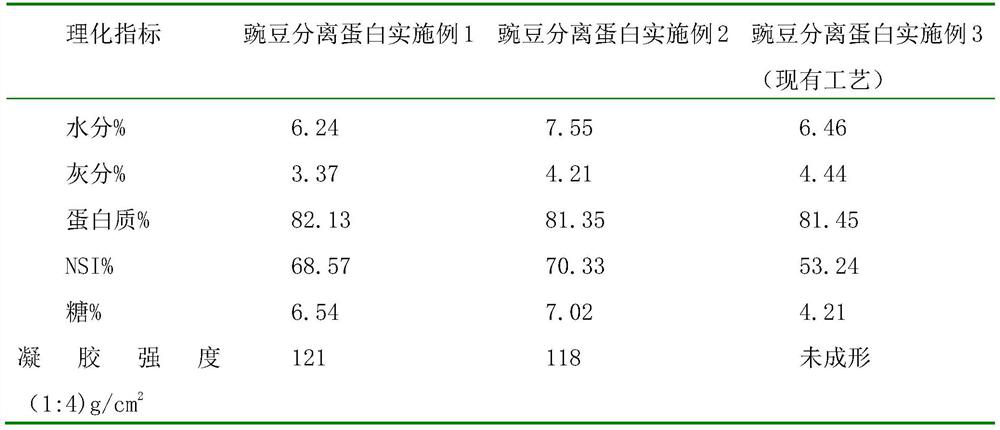

Embodiment 1

[0042] Grind the cleaned and peeled peas with a pulverizer to ensure that more than 90% of the pea flour has a particle size of 74-38μm; mix the pea flour with food processing water at 25±5°C in a ratio of 1:4, and use alkali Adjust the pH of the liquid to 9.0, pump the evenly mixed slurry to the material tank, and keep stirring to ensure that the extraction time is 20 minutes; after the extraction time is up, use a centrifuge to separate the solid from the liquid. The volume fraction of suspended solids in the phase is between 1% and 2%, and the liquid phase is pumped into the reactor; then 0.2% amylase and 0.2% cellulase are added to the liquid phase reactor, and the temperature is controlled at 50±2°C, PH 7.0±0.5, reaction time 10min; after enzymolysis time is up, quickly raise the temperature of the liquid phase to between 80-90°C, and quickly use food-grade hydrochloric acid to adjust the pH of the liquid phase to 4.5±0.3, The liquid phase after pH adjustment is quickly p...

Embodiment 2

[0046]Grind the washed and peeled peas with a pulverizer to ensure that more than 90% of the pea flour particle size is between 74-38μm; mix the pea flour with food processing water at 25±5°C in a ratio of 1:5, and use alkali Adjust the pH of the liquid to 9.5, use a pump to transport the evenly mixed slurry to the material tank, and keep stirring to ensure that the extraction time is within 30 minutes; after the extraction time is up, use a centrifuge to separate the solid from the liquid, pay attention to the separation process Ensure that the volume fraction of suspended solids in the liquid phase is between 1% and 2%, pump the liquid phase into the reactor; then add 0.1% amylase and 0.1% cellulase to the liquid phase reactor, the temperature Control at 50±2°C, pH at 7.0±0.5, and reaction time 15 minutes; after the enzymolysis time is up, quickly raise the temperature of the liquid phase to between 80-90°C, and quickly use food-grade hydrochloric acid to adjust the pH of the...

Embodiment 3

[0049] Embodiment 3: This embodiment is non-glycosylated protein extraction process

[0050] Grind the cleaned and peeled peas with a pulverizer to ensure that more than 90% of the pea flour has a particle size of 74-38μm; mix the pea flour with food processing water at 25±5°C in a ratio of 1:5, and use alkali Adjust the pH of the liquid to 10, and use a pump to transport the evenly mixed slurry to the material tank, and keep stirring to ensure that the extraction time is within 30 minutes; after the extraction time is up, use a centrifuge to separate the solid from the liquid. Exclude the suspended solids to the greatest extent, and then pump the liquid phase into the material tank; quickly raise the temperature of the liquid phase to between 50-65°C, and at the same time quickly use food-grade hydrochloric acid to adjust the pH of the liquid phase to 4.5±0.3, after adjusting the pH The liquid phase of the acid precipitation is quickly pumped into the acid precipitation mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com