Mn-Co-La composite catalyst for catalytic degradation of VOCs in cooperation with discharge plasma as well as preparation method and application of Mn-Co-La composite catalyst

A technology of discharge plasma and composite catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problems of high cost and difficult industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

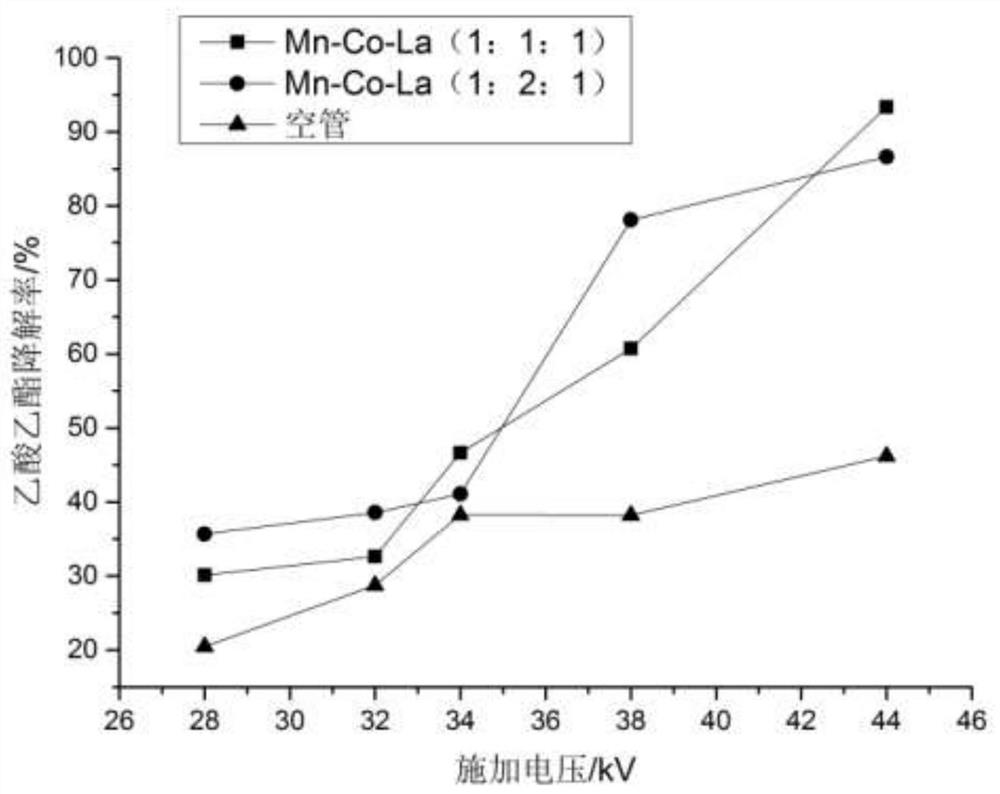

Examples

Embodiment 1

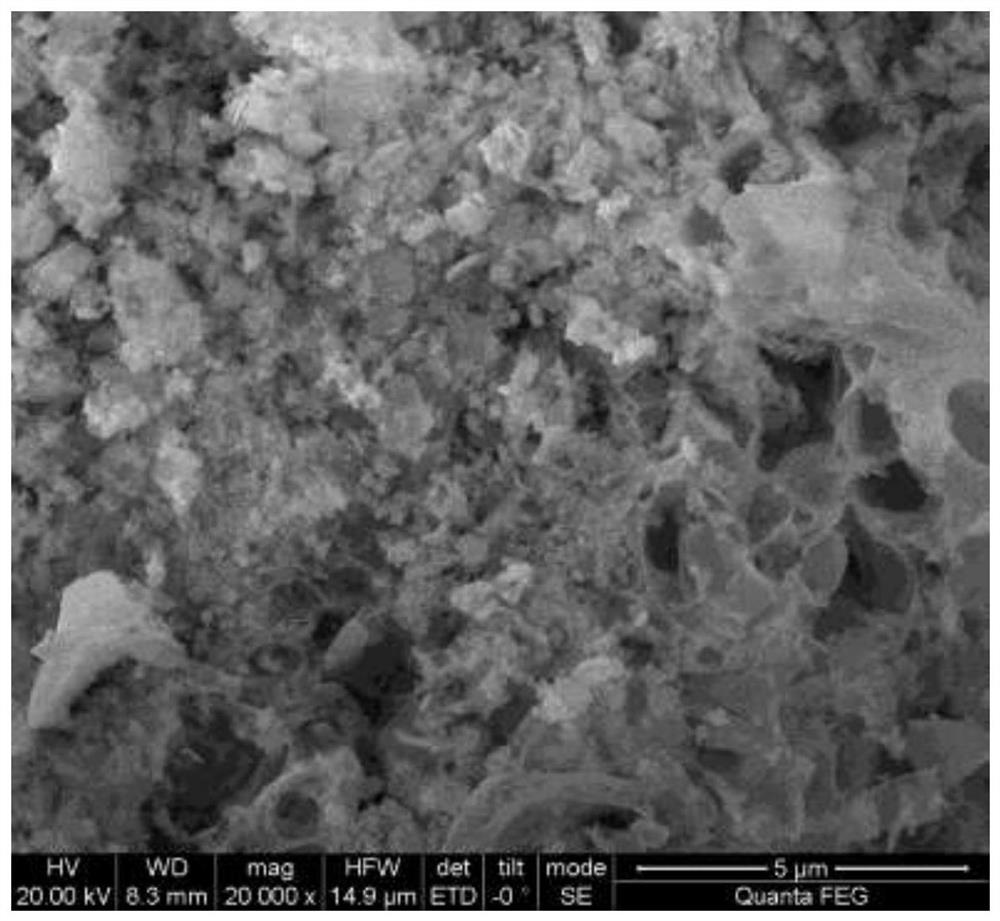

[0044] The preparation method of the Mn-Co-La composite catalyst for degrading VOCs waste gas of the present embodiment comprises the following steps:

[0045] (1) Measure 29.125mL of manganese nitrate, dilute to 250mL with absolute ethanol, prepare 250mL of 0.5mol / L manganese nitrate solution, weigh 36.35g of cobalt nitrate hexahydrate, dilute to 250mL with absolute ethanol, prepare To obtain 250 mL of 0.5 mol / L cobalt nitrate solution, weigh 54.125 g of lanthanum nitrate hexahydrate, and adjust the volume to 250 mL with absolute ethanol to prepare 250 mL of 0.5 mol / L lanthanum nitrate solution. Measure 20 mL each of manganese nitrate, cobalt nitrate, and lanthanum nitrate solutions, pour them into a beaker to mix the three, and stir ultrasonically for 5 minutes;

[0046] (2) Add citric acid monohydrate to the mixed metal alcohol solution obtained in step (1), heat it to 80°C at a heating rate of 3°C / min at 25°C, and add ammonia solution while stirring to adjust the pH to 7 ...

Embodiment 2

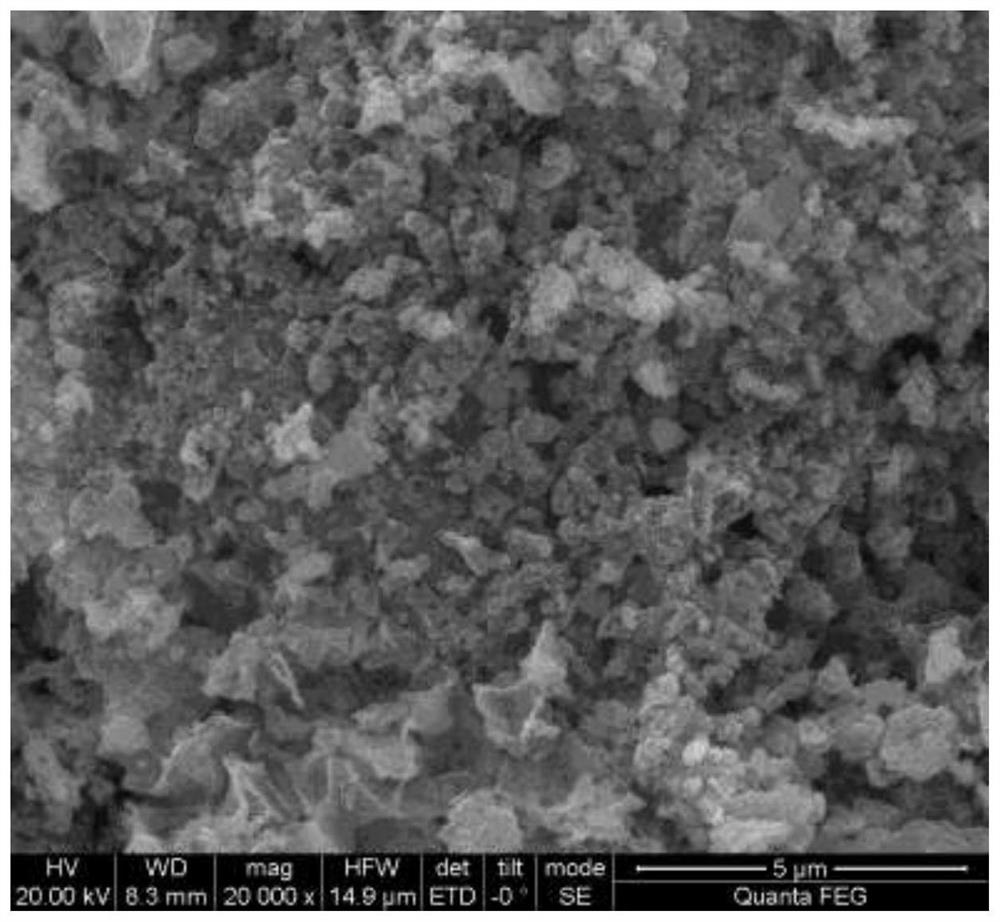

[0050] The preparation method of the Mn-Co-La composite catalyst for degrading VOCs waste gas of the present embodiment comprises the following steps:

[0051] (1) Measure 29.125mL of manganese nitrate, dilute to 250mL with absolute ethanol, prepare 250mL of 0.5mol / L manganese nitrate solution, weigh 36.35g of cobalt nitrate hexahydrate, dilute to 250mL with absolute ethanol, prepare To obtain 250 mL of 0.5 mol / L cobalt nitrate solution, weigh 54.125 g of lanthanum nitrate hexahydrate, and adjust the volume to 250 mL with absolute ethanol to prepare 250 mL of 0.5 mol / L lanthanum nitrate solution. Measure 15mL of manganese nitrate solution, 30mL of cobalt nitrate solution, and 15mL of lanthanum nitrate solution, pour them into a beaker to mix them, and stir them ultrasonically for 5 minutes;

[0052] (2) Add citric acid monohydrate to the mixed metal alcohol solution obtained in step (1), heat it to 80°C at a heating rate of 3°C / min at 25°C, and add ammonia solution while stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com