Method for preparing iodine monochloride at low cost and high efficiency and obtained iodine monochloride

A low-cost technology of iodine monochloride, applied in the direction of inter-halogen compounds, etc., can solve the problems of insufficient contact between solid and gas raw materials, strict requirements for conditions, long reaction time, etc., and achieves outstanding technical effects, low raw material requirements, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

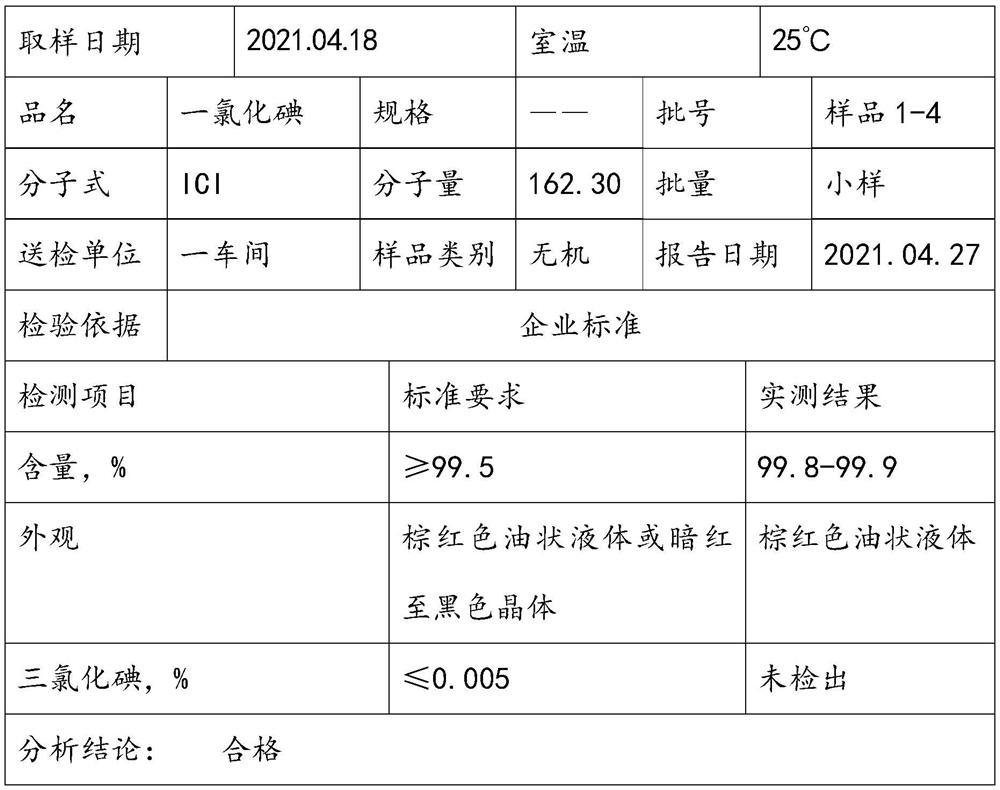

Examples

Embodiment 1

[0023] A method for preparing iodine monochloride with low cost and high efficiency, comprising the following steps:

[0024] S1. Refined iodine dissolving: in a 10L jar, add 10.5kg of dichloromethane, then weigh 5kg of refined iodine, add in dichloromethane in batches under stirring, and stir to dissolve the refined iodine;

[0025] S2. Chlorine gas synthesis and gas washing: Weigh 1870g of potassium permanganate, put it into a 10L large mouth bottle, take a water bath at room temperature, then weigh 9.3kg of hydrochloric acid and put it into a high-level bottle, seal the system well, open the valve to let the hydrochloric acid drip slowly and uniformly into potassium permanganate, stirring continuously, the chlorine produced is washed with saturated sodium chloride solution and sulfuric acid respectively, and then enters the refined iodine and dichloromethane solution through the buffer bottle to synthesize;

[0026] S3. Synthesis: The chlorine gas after washing is fed into ...

Embodiment 2

[0030] A method for preparing iodine monochloride with low cost and high efficiency, comprising the following steps:

[0031] S1. Refined iodine dissolving: in a 10L jar, add 11kg of dichloromethane, then weigh 5kg of refined iodine, add in dichloromethane in batches under stirring, and stir to dissolve the refined iodine;

[0032] S2. Chlorine gas synthesis and gas washing: Weigh 1870g of potassium permanganate, put it into a 10L large mouth bottle, take a water bath at room temperature, then weigh 9.3kg of hydrochloric acid and put it into a high-level bottle, seal the system well, open the valve to let the hydrochloric acid drip slowly and uniformly into potassium permanganate, stirring continuously, the chlorine produced is washed with saturated sodium chloride solution and sulfuric acid respectively, and then enters the refined iodine and dichloromethane solution through the buffer bottle to synthesize;

[0033] S3. Synthesis: The chlorine gas after gas washing is uniform...

Embodiment 3

[0037] A method for preparing iodine monochloride with low cost and high efficiency, comprising the following steps:

[0038] S1. Refined iodine dissolving: in a 10L jar, add 12kg of chloroform, then weigh 5.2kg of refined iodine, add it to the chloroform several times under stirring, and stir to dissolve the refined iodine;

[0039] S2. Chlorine gas synthesis and gas washing: Weigh 1930g of potassium permanganate, put it into a 10L large mouth bottle, put it in a water bath at room temperature, then weigh 9.5kg of hydrochloric acid and put it into a high-level bottle, seal the system well, open the valve to let the hydrochloric acid drip slowly and uniformly into potassium permanganate, continuously stirred, and the chlorine gas produced is washed with saturated sodium chloride solution and sulfuric acid respectively, and then enters the refined iodine and chloroform solution through the buffer bottle to synthesize;

[0040] S3. Synthesis: The chlorine gas after washing is fed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com