Potassium removal process of production system for lithium extraction from ore

A production system and ore technology, applied in the field of lithium salt production and hydrometallurgy, can solve the problems that the solubility of potassium aluminum sulfate is affected by temperature, the process of potassium removal is long, and the operation of potassium removal is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

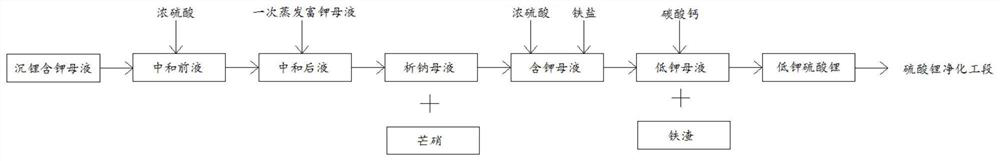

[0049] Such as figure 1 Shown, a kind of ore extracts lithium production system potassium removal process, comprises the following steps:

[0050] Step 1, use 98wt% concentrated sulfuric acid to adjust the pH of lithium-containing potassium-containing mother liquor of the lithium carbonate production line to 3, in order to remove the carbonate group in the pre-neutralization liquid;

[0051] Step 2, using a lithium hydroxide production line to evaporate the potassium-rich mother liquor once to adjust the neutralization pre-liquid to 7 to obtain the neutralization post-liquid;

[0052] Step 3, after the neutralized liquid is evaporated to remove nitrate, a potassium-enriched sodium analysis mother liquor with a potassium content of 5g / L is generated, and the potassium-enriched sodium analysis mother liquor includes lithium sulfate, potassium sulfate, and sodium sulfate;

[0053] Step 4, using 98wt% concentrated sulfuric acid to adjust the pH of the potassium-rich and sodium-ri...

Embodiment 2

[0064] Such as figure 1 Shown, a kind of ore extracts lithium production system potassium removal process, comprises the following steps:

[0065] Step 1, use 98wt% concentrated sulfuric acid to adjust the pH of lithium carbonate production line lithium potassium-containing mother liquor to 2, in order to remove the carbonate group in the neutralization former liquor;

[0066] Step 2, using a lithium hydroxide production line to evaporate the potassium-rich mother liquor once to adjust the neutralization pre-liquid to 5 to obtain the neutralization post-liquid;

[0067] Step 3, after the neutralized liquid is evaporated to remove nitric acid, a potassium-enriched sodium analysis mother liquor with a potassium content of 1.8g / L is generated, and the potassium-enriched sodium analysis mother liquor includes lithium sulfate, potassium sulfate, and sodium sulfate;

[0068] Step 4, using 98wt% concentrated sulfuric acid to adjust the pH of the potassium-rich and sodium-rich mother...

Embodiment 3

[0079] Such as figure 1 Shown, a kind of ore extracts lithium production system potassium removal process, comprises the following steps:

[0080] Step 1, adjust the pH of lithium carbonate production line lithium potassium-containing mother liquor to 1 with 98wt% concentrated sulfuric acid, in order to remove the carbonate group in the pre-neutralization liquor;

[0081] Step 2, using a lithium hydroxide production line to evaporate the potassium-rich mother liquor once to adjust the pre-neutralization liquid to 6 to obtain the post-neutralization liquid;

[0082] Step 3, after the neutralized liquid is evaporated to remove the nitric acid, a potassium-rich sodium analysis mother liquor with a potassium content of 8.2g / L is generated, and the potassium-rich sodium analysis mother liquor includes lithium sulfate, potassium sulfate, and sodium sulfate;

[0083] Step 4, use 98wt% concentrated sulfuric acid to adjust the pH of the mother liquor rich in potassium and sodium analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com