Preparation method of 4, 4 '-dichlorodiphenyl sulfone

A technology of dichlorodiphenyl sulfone and dichlorodiphenyl sulfoxide, which is applied in the field of preparation of 4,4´-dichlorodiphenyl sulfone, can solve complex catalyst preparation process, equipment corrosion, special quaternary ammonium salt phase transfer agent Expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

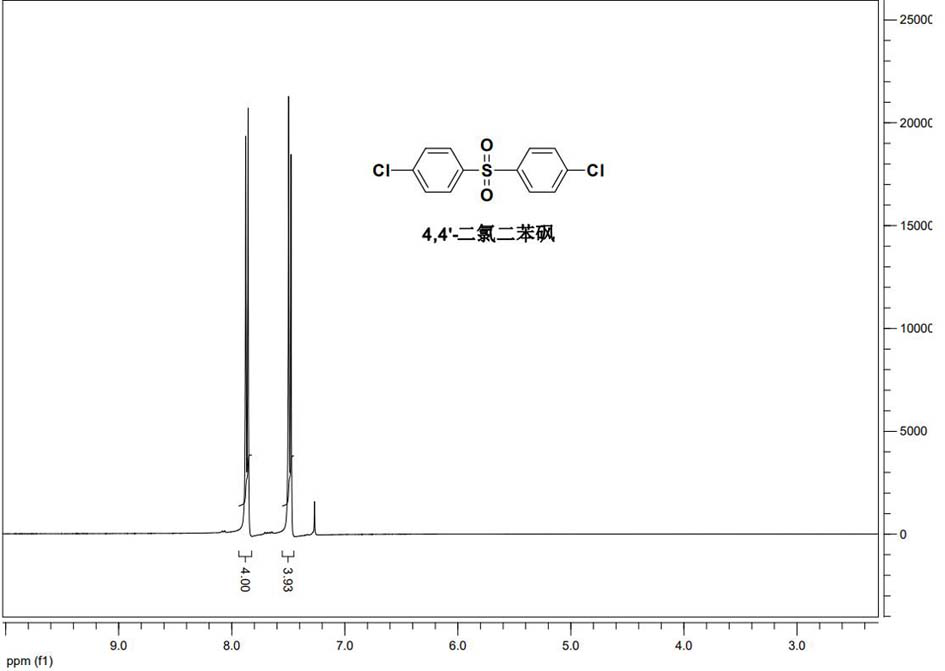

[0043] The preparation method of described 4,4'-dichlorodiphenylsulfone comprises the following steps:

[0044] (1) Mix 0.40g ammonium molybdate, 0.37g oxalic acid, and 24.75g 27.5% hydrogen peroxide for 1 hour at room temperature to obtain a mixed solution;

[0045] (2) Add the above mixed solution dropwise into a four-neck flask containing 54.50g of 4,4´-dichlorodiphenylsulfoxide and 110.00g of dichloropropane, raise the temperature to 80°C, and react for 5 hours;

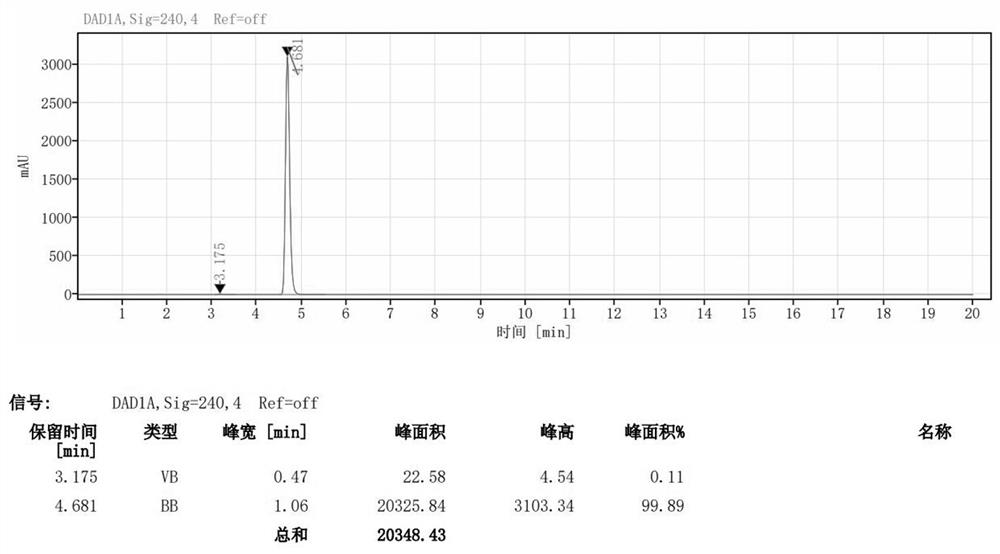

[0046] (3) After the reaction, add 0.17g of activated carbon to the reaction liquid to react for 0.5 hours, remove impurities and decolorize, filter out the activated carbon while it is hot, cool the resulting solution to 5°C, cool and crystallize for 1.5 hours, and filter again to obtain filter cake and remaining Filtrate, the filter cake was dried at 85°C for 7 hours to obtain high-purity 4,4´-dichlorodiphenylsulfone; the yield of the obtained 4,4´-dichlorodiphenylsulfone was 97.2%, and the purity was tested by...

Embodiment 2

[0049] The preparation method of described 4,4'-dichlorodiphenylsulfone comprises the following steps:

[0050] (1) Mix 0.40g ammonium molybdate, 0.37g oxalic acid, and 24.75g 27.5% hydrogen peroxide for 1 hour at room temperature to obtain a mixed solution;

[0051] (2) Add the above mixed solution dropwise into a four-neck flask containing 54.50g of 4,4´-dichlorodiphenyl sulfoxide and 110.00g of chlorobenzene, raise the temperature to 80°C, and react for 5 hours;

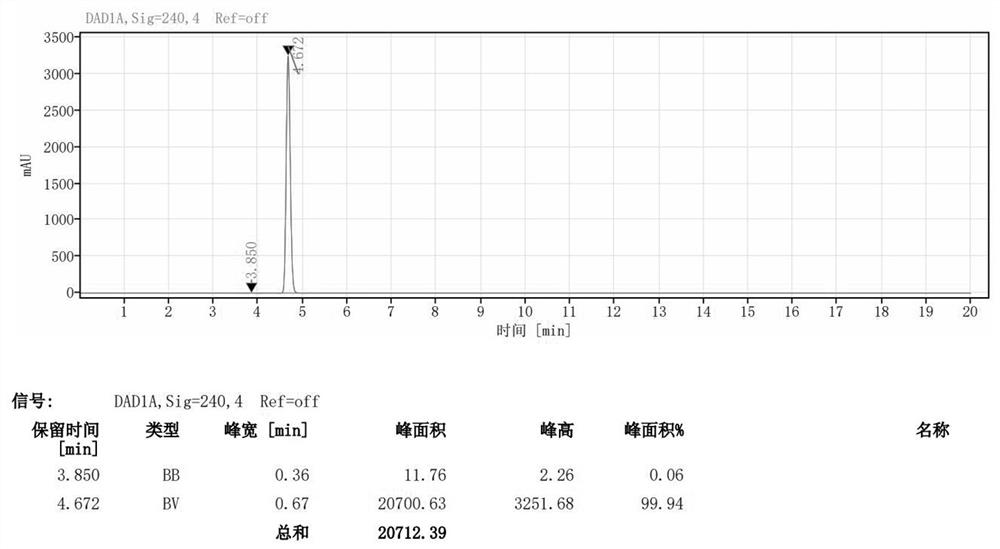

[0052] (3) After the reaction, add 1.00g of activated carbon to the reaction liquid to react for 0.5 hours, remove impurities and decolorize, filter out the activated carbon while it is hot, cool the resulting solution to 5°C, cool and crystallize for 1.5 hours, and filter again to obtain filter cake and remaining Filtrate, the filter cake was dried at 85°C for 7 hours to obtain high-purity 4,4´-dichlorodiphenylsulfone; the yield of the obtained 4,4´-dichlorodiphenylsulfone was 97.8%, and the purity was tested by ...

Embodiment 3

[0055]The preparation method of described 4,4'-dichlorodiphenylsulfone comprises the following steps:

[0056] (1) Mix 0.40g ammonium molybdate, 0.42g malonic acid, and 24.75g 27.5% hydrogen peroxide for 1 hour at room temperature to obtain a mixed solution;

[0057] (2) Add the above mixed solution dropwise into a four-neck flask containing 54.50g of 4,4´-dichlorodiphenyl sulfoxide and 110.00g of chlorobenzene, raise the temperature to 80°C, and react for 5 hours;

[0058] (3) After the reaction, add 1.00g of activated carbon to the reaction liquid to react for 0.5 hours, remove impurities and decolorize, filter out the activated carbon while it is hot, cool the resulting solution to 5°C, cool and crystallize for 1.5 hours, and filter again to obtain filter cake and remaining Filtrate, the filter cake was dried at 85°C for 7 hours to obtain high-purity 4,4´-dichlorodiphenylsulfone; the yield of the obtained 4,4´-dichlorodiphenylsulfone was 97.3%, and the purity was tested by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com