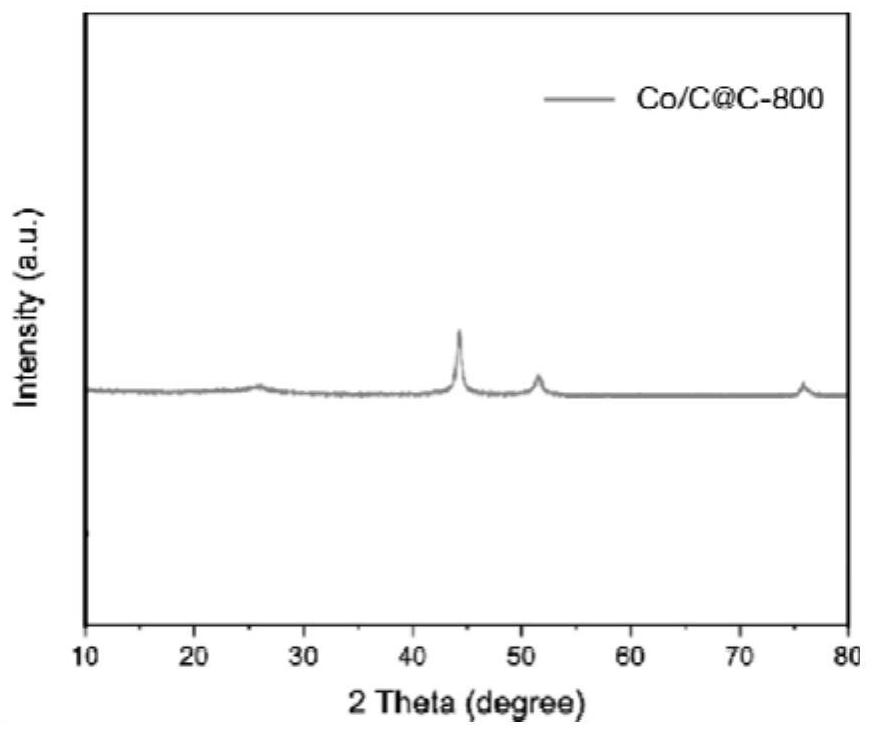

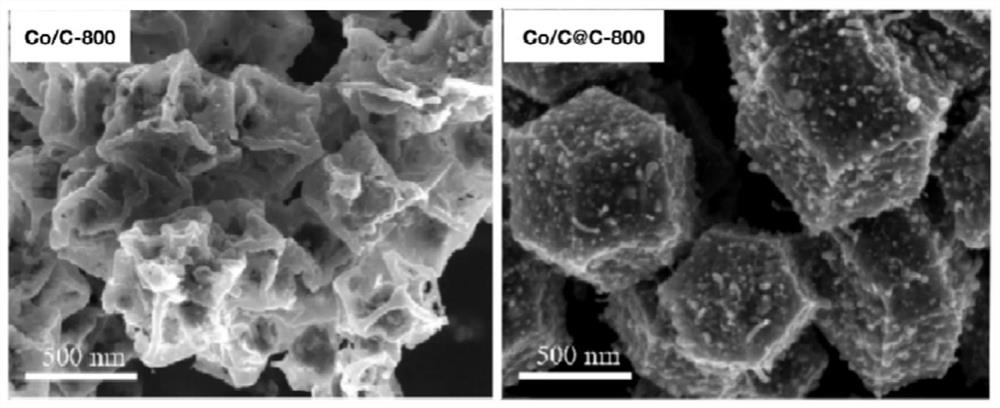

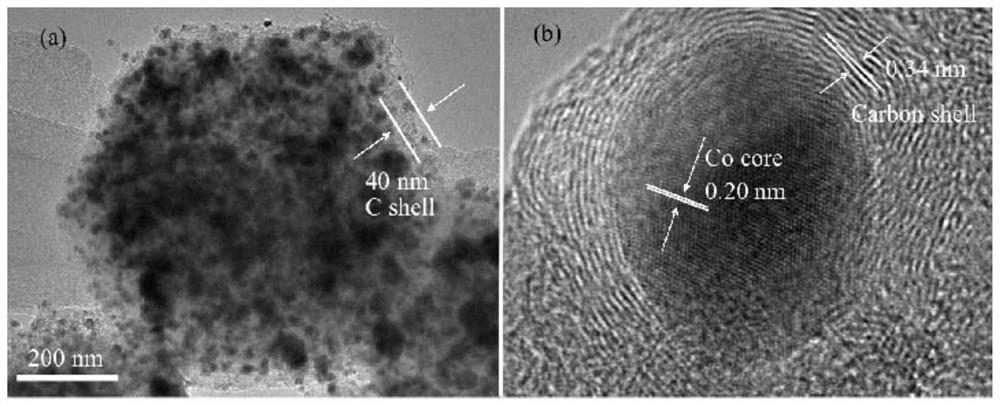

Electromagnetic wave-absorbing composite material with amorphous carbon shell and preparation method of electromagnetic wave-absorbing composite material

An amorphous carbon and electromagnetic wave-absorbing technology, which is applied in the field of equipment or components to shield electric or magnetic fields, can solve problems such as reducing multi-interface structures, excessive agglomeration of magnetic metal particles, and affecting material impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An electromagnetic wave-absorbing composite material with an amorphous carbon shell, the preparation method of which is as follows:

[0031] 1) Weigh 2.44g cobalt nitrate hexahydrate, 2.5g zinc nitrate hexahydrate and 2.76g 2-methylimidazole, set aside;

[0032] 2) The cobalt nitrate hexahydrate, zinc nitrate hexahydrate and 2-methylimidazole weighed in step 1) were dissolved in 135mL methanol respectively to obtain cobalt nitrate methanol solution, zinc nitrate methanol solution, and 2-methylimidazole methanol solution;

[0033] 3) Slowly and uniformly drop the 2-methylimidazole methanol solution obtained in step 2) into the cobalt nitrate methanol solution, after the dropwise addition, stir and react at room temperature for 4 hours to obtain a methanol solution containing precipitate 1, and then add the zinc nitrate methanol The solution was added to the methanol solution containing precipitate 1, stirred at room temperature for 30 minutes to obtain a methanol solutio...

Embodiment 2

[0044] An electromagnetic wave-absorbing composite material with an amorphous carbon shell, the preparation method of which is as follows:

[0045] 1) Weigh 1.67g ferrous chloride tetrahydrate, 2.5g zinc nitrate hexahydrate and 2.76g 2-methylimidazole, set aside;

[0046] 2) Ferrous chloride tetrahydrate, zinc nitrate hexahydrate and 2-methylimidazole that step 1) weighed are dissolved in 135mL methanol respectively, obtain the methanol solution of ferrous chloride, zinc nitrate methanol solution, 2-methylimidazole Methanol solution of imidazole;

[0047] 3) Slowly and uniformly drop the 2-methylimidazole methanol solution obtained in step 2) into the methanol solution of ferrous chloride in the glove box in an air-isolated state, and stir at room temperature for 4 hours after the dropwise addition to obtain precipitate 1 Then add the zinc nitrate methanol solution into the methanol solution containing precipitate 1, stir and react at room temperature for 30 minutes to obtain...

Embodiment 3

[0050] An electromagnetic wave-absorbing composite material with an amorphous carbon shell, the preparation method of which is as follows:

[0051] 1) Weigh 2.44g nickel nitrate hexahydrate, 2.5g zinc nitrate hexahydrate and 2.76g 2-methylimidazole, set aside;

[0052] 2) Nickel nitrate hexahydrate, zinc nitrate hexahydrate and 2-methylimidazole that were weighed in step 1) were dissolved in 135mL methanol respectively to obtain methanol solution of nickel nitrate, methanol solution of zinc nitrate, and methanol solution of 2-methylimidazole ;

[0053] 3) Slowly and uniformly drop the 2-methylimidazole methanol solution obtained in step 2) into the methanol solution of nickel nitrate, after the drop is completed, perform a hydrothermal reaction at 120° C. for 4 hours to obtain a methanol solution containing precipitate 1, and then add the Add the zinc nitrate methanol solution into the methanol solution containing the precipitate 1, stir and react at room temperature for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com