Novel slow-expansion plugging material and preparation method thereof

A plugging material and slow expansion technology, applied in the field of plugging materials, can solve problems such as failure to achieve a good plugging effect, loss of continuous expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

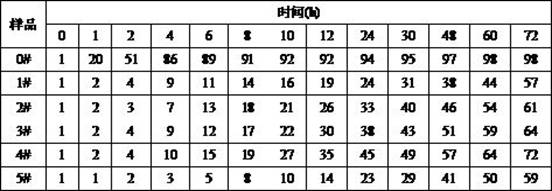

Examples

Embodiment 1

[0023] Add 100g of distilled water, 10g of acrylamide, 10g of 2-acrylamido-2-methylpropanesulfonic acid, 0.04g of a mixture of sodium sulfite and ammonium persulfate, 0.004g of N,N-methylenebisacrylamide, and 11.912g of bentonite into the reactor , 5°C, high-speed stirring and mixing under nitrogen protection conditions, slowly warming up to 20°C, to obtain a viscous system, then pour it into a mixture of 8g methyl methacrylate and 2-acrylamido-2-methylpropane In a reactor containing a mixture of methyl sulfonate (mass ratio 2.5:1), 0.004g divinylbenzene, and 0.04g benzoyl peroxide, stir at a high speed of 5000 rpm for 60min, and slowly heat up to 50°C , stop stirring, and let it stand for 1 hour to react. After the product is dried and pulverized, it becomes slow-swelling plugging material 1#.

Embodiment 2

[0025] Add 100g of distilled water, 14g of acrylamide, 14g of acrylic acid, 0.2g of a mixture of sodium sulfite and ammonium persulfate, 0.12g of N,N-methylenebisacrylamide, and 9.36g of bentonite into the reactor, and stir and mix at a high speed under nitrogen protection at 3°C , slowly warming up to 20°C to obtain a viscous system, which was then poured into a mixture containing 2g of methyl methacrylate and 2-acrylamido-2-methylpropanesulfonate (mass ratio 2.5: 1) In a reactor containing 0.12g of divinylbenzene and 0.2g of benzoyl peroxide, stir at a high speed of 5000 rpm for 60 minutes, slowly raise the temperature to 50°C, stop stirring, and let it stand for 1 hour to react. After being dried and pulverized, it becomes slow-swelling plugging material 2#.

Embodiment 3

[0027] Add 100g of distilled water, 8g of acrylic acid, 8g of methacrylamide, 0.2g of a mixture of sodium sulfite and ammonium persulfate, 0.12g of N,N-methylenebisacrylamide, and 15.36g of kaolin into the reactor. Stir and mix, and slowly heat up to 20°C to obtain a viscous system, which is then poured into a mixture containing 8g of ethyl acrylate and 2-acrylamido-2-methylpropanesulfonate (mass ratio 2.5: 1) In a reactor containing 0.12g of divinylbenzene and 0.2g of benzoyl peroxide, stir at a high speed of 5000 rpm for 30 minutes, slowly raise the temperature to 60°C, stop stirring, and let it stand for 4 hours to react. After being dried and pulverized, it becomes slow-swelling plugging material 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com