Absorbable high-performance nanofiber woven tendon patch and preparation method thereof

A nanofiber, high-performance technology, applied in the field of artificial tendons and artificial ligaments in sports medicine, can solve the problems of poor mechanical properties of tendon scaffolds, messy fibers, and unsatisfactory conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

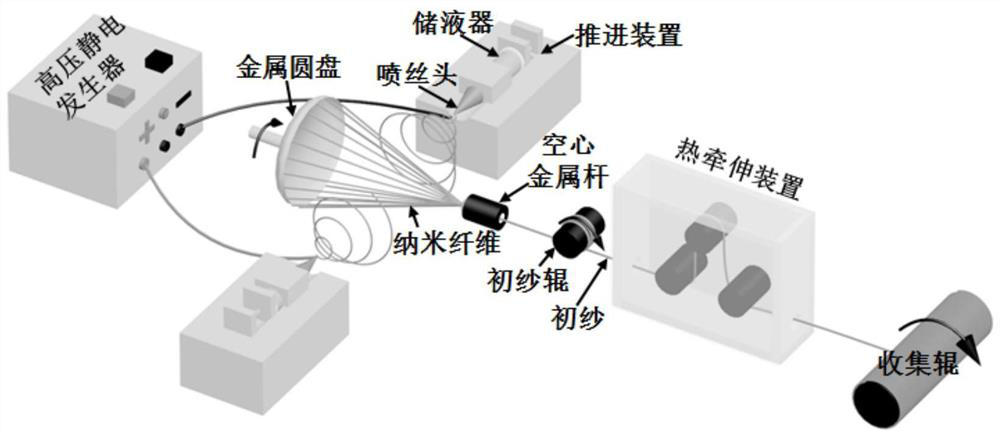

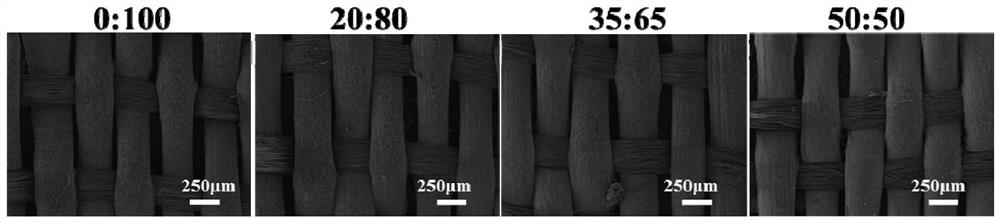

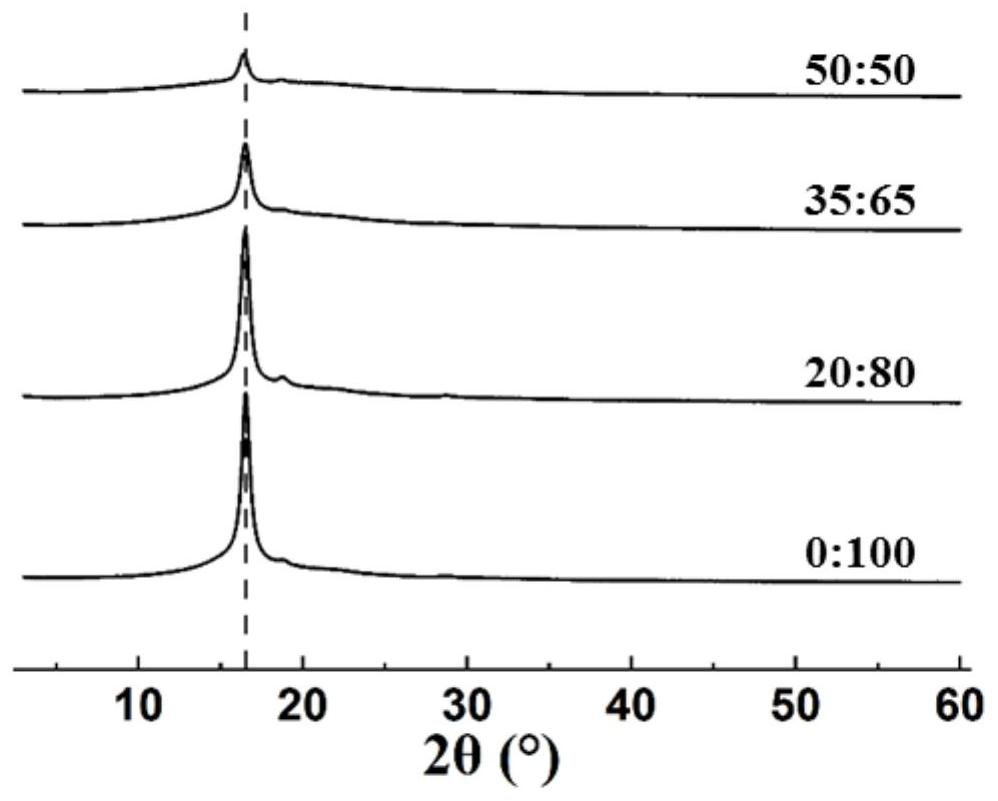

[0045] An absorbable high-performance nanofiber woven tendon patch, the tendon patch is woven from warp yarns and weft yarns, wherein the weft yarn direction constitutes the longitudinal direction of the tendon patch, and the warp direction constitutes the transverse direction of the tendon patch; the warp yarn is biodegradable micron Fiber yarn or biodegradable nanofiber yarn, the weft yarn is biodegradable nanofiber yarn; biodegradable nanofiber yarn is a twisted primary yarn formed by twisting oriented nanofibers obtained by electrospinning technology , and then the pure twisted nanofiber yarn prepared by thermal drawing treatment of the twisted initial yarn, such as figure 1 shown. In this embodiment, the biodegradable nanofiber yarn is a pure twisted nanofiber yarn obtained by electrospinning high polymer poly-L-lactic acid (PLLA), and then the obtained pure twisted nanofiber yarn is used as a weft yarn , with biodegradable PLLA micron fiber yarn as the warp, the appeara...

Embodiment 2

[0051] The same as Example 1 will not be repeated, the difference is that in this example, the biodegradable nanofiber yarn is made of high polymer silk fibroin (SF) and poly-L-lactic acid (PLLA) mixed electrospun Purely twisted nanofiber yarns obtained from silk were then woven from warp and weft yarns to form a strip-like tendon patch. Wherein, the warp and weft yarn density of the tendon patch of the tendon patch is 63 threads / 10cm×150 threads / 10cm.

[0052] When preparing the spinning solution, use an electronic balance to weigh 0.2g of SF and 0.8g of PLLA, then dissolve them in 10mL of hexafluoroisopropanol, and stir overnight on a magnetic stirrer at room temperature to prepare the mass concentration Percentage is 10% SF / PLLA blended spinning solution; Then the SF / PLLA spinning solution that the mass concentration percentage that makes is 10% is loaded in the double reservoir, obtains biodegradable nanofiber yarn; Finally by In the weaving process of textile and weaving...

Embodiment 3

[0054] The similarities with Example 2 will not be repeated, the difference is that in this embodiment, the warp and weft yarn density of the tendon patch of the tendon patch is 138 yarns / 10cm×238 yarns / 10cm.

[0055] When preparing the spinning solution, use an electronic balance to weigh 0.35g of SF and 0.65g of PLLA, then dissolve them in 10mL of hexafluoroisopropanol, and stir overnight on a magnetic stirrer at room temperature to prepare the mass concentration Percentage is 10% SF / PLLA blended spinning solution; Then the SF / PLLA spinning solution that the mass concentration percentage that makes is 10% is loaded in the double reservoir, obtains biodegradable nanofiber yarn; Finally by In the weaving process of textile and weaving technology, the prepared biodegradable nanofiber yarn is used as the weft yarn, and the biodegradable PLLA micron fiber yarn is used as the warp yarn. Interweaving according to the plain weave on the loom to prepare absorbable and high-performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com