Manufacturing method of n-type low-resistivity 4H-SiC ohmic contact

A technology of ohmic contact and low resistivity, which is applied in the field of microelectronics manufacturing technology, can solve problems such as high product stability, high yield rate, and academic controversy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

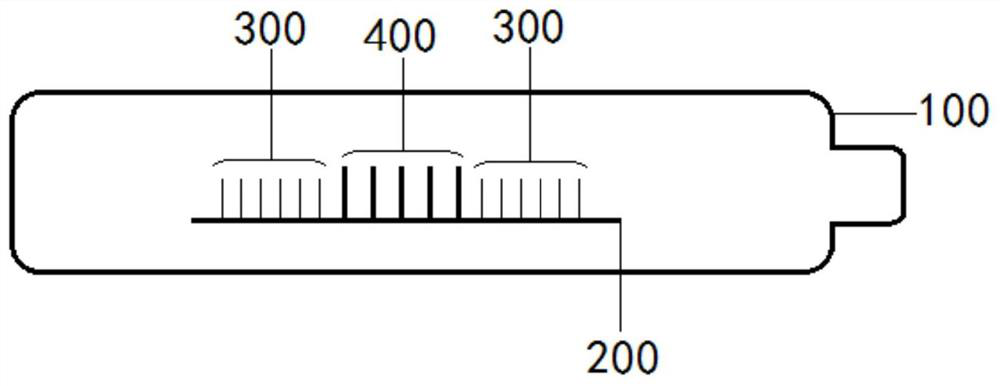

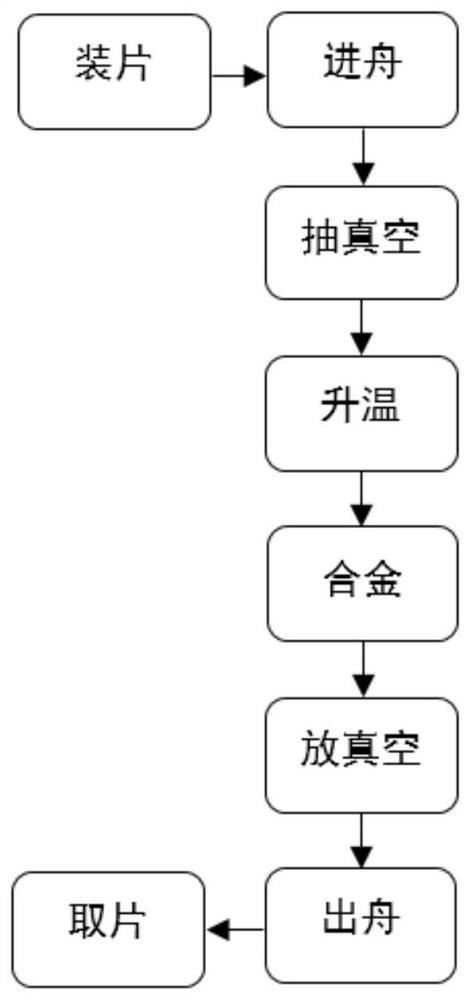

[0042] like Figure 4 As shown, an n-type low-resistivity 4H-SiC ohmic contact manufacturing method provided in an embodiment of the present invention includes:

[0043] Step 1, select the n-type 4H-SiC heavily doped substrate 1, in the embodiment of the present invention, the doping concentration range of the n-type 4H-SiC heavily doped substrate 1 is 10 17 cm -3 ~10 18 cm -3 , the thickness of the n-type 4H-SiC heavily doped substrate 1 is 50 μm to 400 μm;

[0044] Step 2, using a mixed solution of concentrated sulfuric acid and hydrogen peroxide to fully clean the back surface of the n-type 4H-SiC heavily doped substrate 1 to remove organic matter and pollutants on the back surface of the substrate.

[0045] Step 3, using a mixed solution of HF acid and water to etch the back surface of the n-type 4H-SiC heavily doped substrate 1 to remove the SiO naturally generated on the substrate surface 2 .

[0046] Step 4, depositing a metal nickel layer 2 on the back surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com