A kind of functional ionic liquid-gelatin composite film and preparation method thereof

A technology of ionic liquid and composite membrane, which is applied in the fields of vacuum drying membrane formation, β-cyclodextrin inclusion compound to prepare casting solution by physical blending, and preparation of functional ionic liquid-gelatin composite membrane, and achieves abundant preparation effect of means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

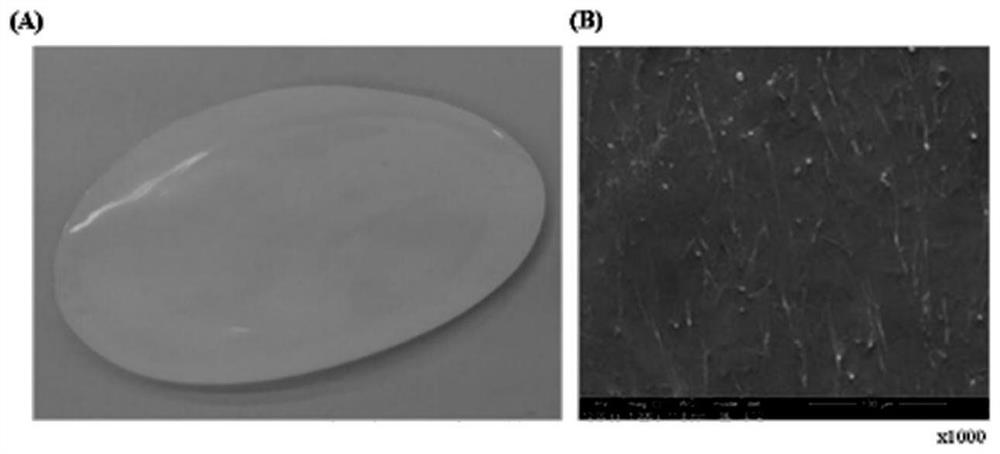

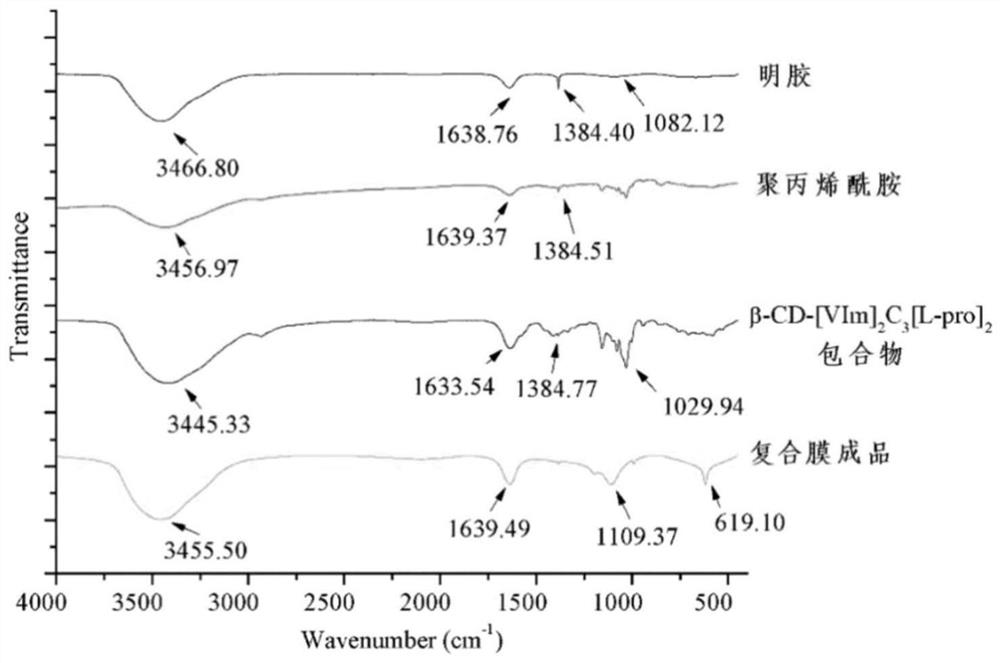

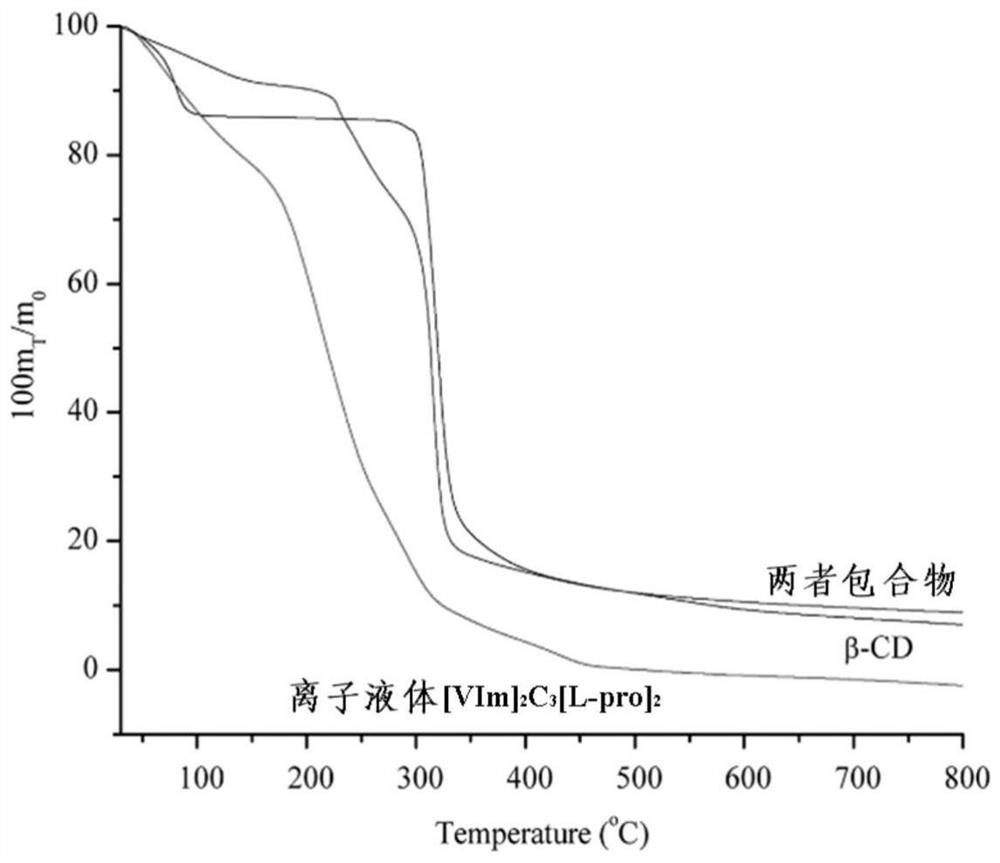

[0028] Example 1: Preparation of gelatin / porogen system with filtration function

[0029] The gelatin aqueous solution with a mass fraction of 4~12% and a porogen aqueous solution with a mass fraction of 1~7% (porogens include: polyacrylamide, or sodium chloride, or polyvinylpyrrolidone) are mixed with a certain ratio. (m 明胶 / m 致孔剂 =9 / 1, 8 / 2, 7 / 3, 6 / 4) at 40 o Fully stirred at C for 1 h, cooled to room temperature; poured 0.5-2.5 mL of the casting solution into a Buchner funnel with a nylon filter membrane (50 mm in diameter) to form a film, and vacuum-dried at room temperature overnight. Before use, swell with deionized water for 30 min, then pour the deionized water, and wash the membrane 3 times with water, and finally use filter paper to absorb the moisture on the surface of the membrane for use. The permeability of the membrane was tested under a certain pressure difference (vacuum degree≤0.8 MPa). Including the concentration of gelatin solution, the type of porogen, ...

Embodiment 2

[0032] Example 2: Ionic liquid [C 4 mim][BF 4 ]@Preparation of gelatin composite films

[0033] The gelatin aqueous solution with a mass fraction of 8%, a polyacrylamide aqueous solution with a mass fraction of 5%, and the inclusion complex of ionic liquid and β-cyclodextrin (n ILs : n β-CD =1:1), with the ratio as m 明胶 : m 致孔剂 : m β-CD-IL =8:2:0.3 at 40 o Fully stirred at C for 1 h, poured 1 mL of the casting solution into a Buchner funnel with a nylon filter membrane (50 mm in diameter) to form a film, and vacuum-dried at room temperature overnight. The resulting film had an average thickness of 0.1 mm.

Embodiment 3

[0034] Example 3: Ionic liquid [C 4 mim][NTf 2 ]@Preparation of gelatin composite films

[0035] The gelatin aqueous solution with a mass fraction of 8%, a polyacrylamide aqueous solution with a mass fraction of 5%, and the inclusion complex of ionic liquid and β-cyclodextrin (n ILs : n β-CD =1:1), with the ratio as m 明胶 : m 致孔剂 : m β-CD-IL =8:2:1 at 40 o Fully stirred at C for 1 h, cooled to room temperature, poured 1 mL of the casting solution onto a Buchner funnel with a nylon filter membrane (50 mm in diameter), and vacuum-dried overnight at room temperature. The resulting film had an average thickness of 0.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com