Prediction method and device for industrial circulating cooling water

A technology of circulating cooling water, forecasting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

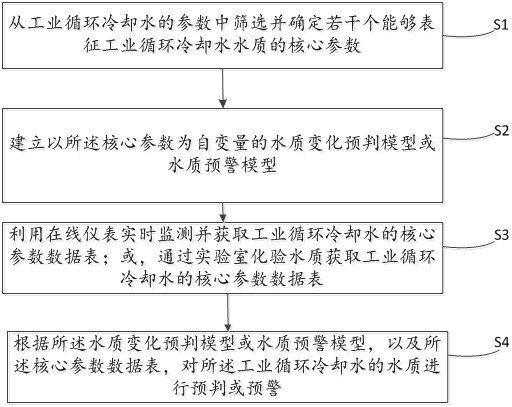

[0041] See figure 1 Prediction method shown in industrial cooling water, which prediction method comprising the steps of:

[0042] Step S1, the filter is capable of characterizing and determining the number of industrial cooling water quality parameter from the parameter core industrial cooling water.

[0043] Circulating water monitoring parameters are divided into several categories: 1) related to the scaling tendency, such as salinity, alkalinity, calcium ion concentration, total hardness, concentration rate, pH and soluble silica and the like; 2) with the corrosive and anion concentration trends related to corrosion, such as conductivity, chloride ions, iron ions, sulfate ions, pH, concentration rate; 3) and the survival and development of microorganisms related microbial and corrosion, such as COD, chlorine, sulfide , ammonia nitrogen, total number of bacteria, suspended solids, turbidity; 4) related to water treatment chemicals, such as water, organic phosphorus stabilizing ...

specific Embodiment approach

[0103] In a specific embodiment, the step 5 comprises:

[0104] When the specific implementation process, may also be implemented to control the dosage and dosage concentrations according to different control parameters, specifically:

[0105] TP can, the quality parameters of the ORP and conductivity, corrosion inhibitor and biocide were adjusted dosing concentration, the conductivity calculated by feedback regulation of concentration and fill water displacement;

[0106] The stability parameters directly reflect further corrosion and scaling tendency of the water quality adjusting the dose of the inhibitor and a dispersant;

[0107] For example, in practice, it may be stably integrated quality parameters such as Ryznar Stability Index (RSI) and other parameters, corrosion and scaling tendency of a direct reflection of the circulating cooling water, adjusting the intensity according to corrosion or fouling of the dosing recipe scale dose of agent and corrosion inhibitor.

[0108]...

Embodiment 2

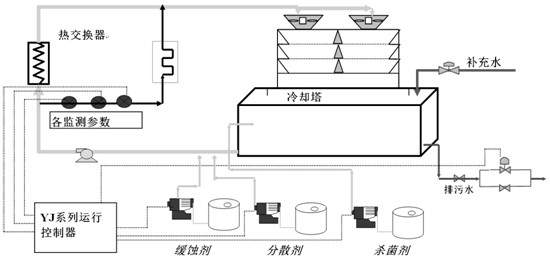

[0111] See figure 2 A device for processing industrial cooling water shown, preferably the processing means employing the prediction method disclosed in Example 1 is processed. The processing apparatus comprises a series of pipe or equipment monitoring instruments, heat exchangers, cooling towers and the sump, each of the circulating cooling water system can be connected to the water collection tank on the connected instrument and the order of the system is not particularly limited and may be .

[0112] And provided with a water fill the sump and outfall the serial access pipeline further adding means with a drug, the agent addition device is controlled by the control system, said control system further respective monitoring instruments or instrument electrically connected, for obtaining the parameters.

[0113] The control needs understood, the control system software may be executed in the above-described method of Example 1, or the control system implementing the method under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com