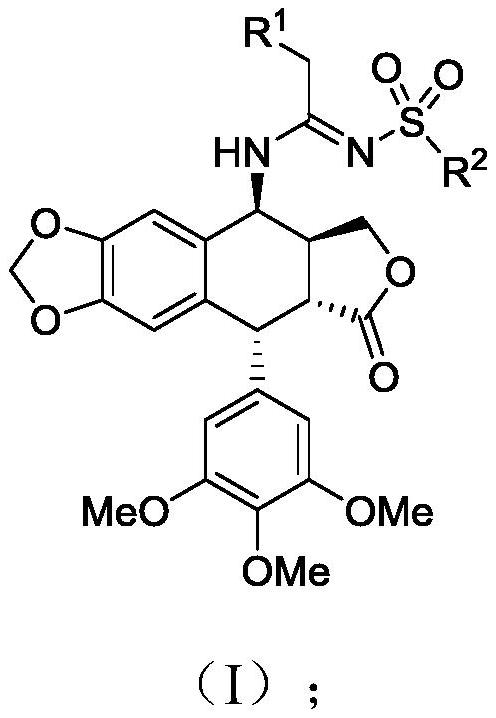

Podophyllotoxin structure modified derivative and preparation method thereof

A technology for podophyllotoxin and epipodophyllotoxin is applied in the field of structure-modified derivatives of podophyllotoxin and the preparation thereof, which can solve the problems of difficult modification and modification of podophyllotoxin structure, and achieves good application value and potential, production and production. High efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]

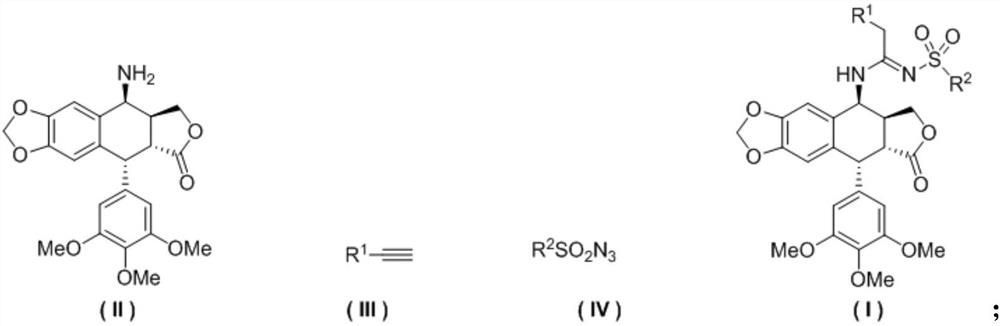

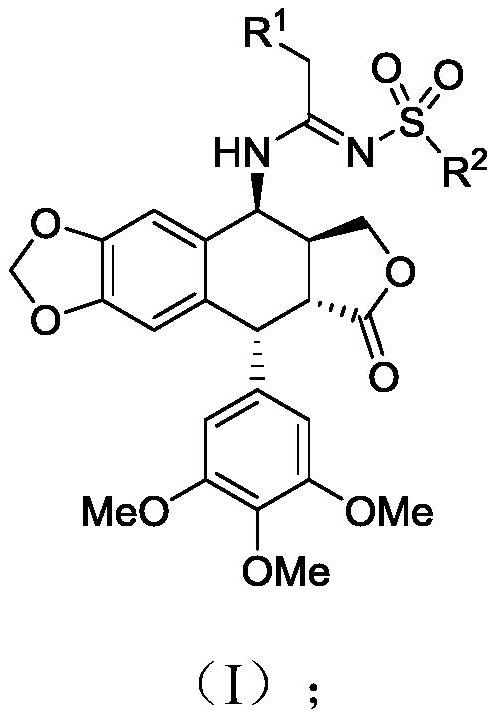

[0034] In acetonitrile, add the compounds of the above formulas (II), (III) and (IV), copper iodide (CuI), triethylamine, then raise the temperature to 25°C, and stir and seal the reaction at this temperature for 24h; wherein, The mol ratio of formula (II) compound and cuprous iodide (CuI) is 1:0.05, the mol ratio of formula (II) compound and triethylamine is 1:0.1, formula (II) compound and (III), (IV ) compound in a molar ratio of 1:1:1, and the ratio of the compound of formula (II) in millimoles (mmol) to acetonitrile in milliliters (ml) is 1:5.

[0035]After the reaction, the reaction system was naturally cooled to room temperature, concentrated by rotary evaporation to obtain a crude product, which was subjected to 300-400 mesh silica gel column chromatography, using ethyl acetate and petroleum ether mixture as eluent, wherein acetic acid The volume ratio of ethyl ester and sherwood oil is 1:5, thereby obtains the target product formula (I) compound (C) of whi...

Embodiment 2

[0040]

[0041] In acetonitrile, add the compounds of the above formulas (II), (III) and (IV), copper iodide (CuI), and triethylamine, then raise the temperature to 40°C, and stir and seal the reaction at this temperature for 12h; wherein, The molar ratio of formula (II) compound and cuprous iodide (CuI) is 1:0.2, the molar ratio of formula (II) compound and triethylamine is 1:0.2, formula (II) compound and (III), (IV ) compound in a molar ratio of 1:2:2, and the ratio of the compound of formula (II) in millimoles (mmol) to acetonitrile in milliliters (ml) is 1:8.

[0042] After the reaction, the reaction system was naturally cooled to room temperature, and the solvent was distilled off under reduced pressure to obtain a crude product. The crude product was subjected to 200-300 mesh silica gel column chromatography, using a mixture of ethyl acetate and petroleum ether as the eluent, wherein The volume ratio of ethyl acetate and sherwood oil is 1:8, thereby obtains the targe...

Embodiment 3

[0047]

[0048] In acetonitrile, add the compounds of the above formulas (II), (III) and (IV), copper iodide (CuI), triethylamine, then raise the temperature to 30°C, and stir and seal the reaction at this temperature for 8h; wherein, The molar ratio of formula (II) compound and cuprous iodide (CuI) is 1:0.15, the molar ratio of formula (II) compound and triethylamine is 1:0.3, formula (II) compound and (III), (IV ) compound in a molar ratio of 1:1.5:1.5, and the ratio of the compound of formula (II) in millimoles (mmol) to acetonitrile in milliliters (ml) is 1:6.

[0049] After the reaction, the reaction system was naturally cooled to room temperature, and the solvent was distilled off under reduced pressure to obtain a crude product. The crude product was subjected to 200-300 mesh silica gel column chromatography, using a mixture of ethyl acetate and petroleum ether as the eluent, wherein The volume ratio of ethyl acetate and sherwood oil is 1:6, thereby obtains the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com