Selective absorbing material as well as preparation method and application thereof

An absorbing material and selective technology, applied in the application field of polymer materials, can solve the problems of difficult desorption, complicated regeneration of adsorbents, and small adsorption capacity, and achieve the effects of simple preparation method, fast absorption rate and large absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

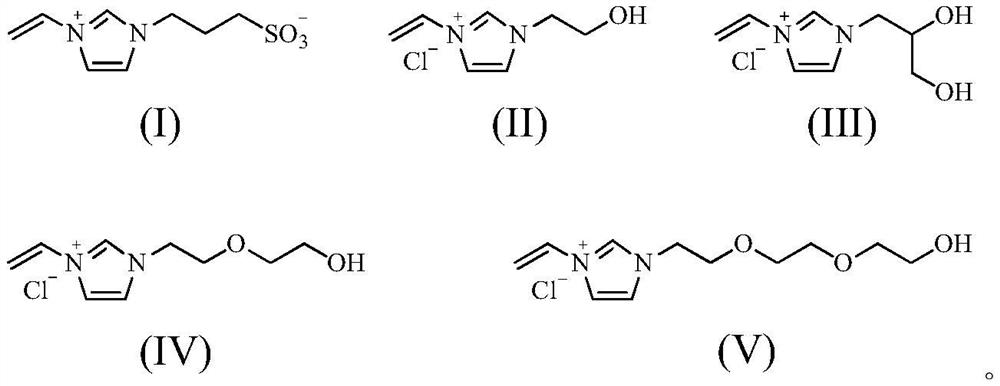

[0024] Example 1: Preparation of Selectively Absorbent Material A

[0025] 1.58 g of 1-vinyl-3-(3-sulfopropyl) imidazolium internal salt, 0.50 g of sodium p-styrenesulfonate and 0.12 g of 3,3'-(triethylene glycol) bis(1 -vinyl-3-imidazolium) dibromide was dissolved in 5 milliliters of deionized water, added to a 50 milliliter two-necked flask, under nitrogen protection, the temperature was raised to 80 ° C, and 0.11 gram of initiator AIBN was added immediately, and then continued to stir for 24 Hour. After the reaction, the obtained cross-linked polymer was dispersed in a 1 mol / L sulfuric acid aqueous solution, and stirred at room temperature for 24 hours. After stirring, it was washed several times with deionized water, methanol and acetone, and dried under vacuum at 60° C. for 24 hours to obtain the target selective absorption material, which was named A, and the yield reached 86%.

Embodiment 2

[0026] Example 2: Absorption capacity test of selective absorbent material A in a single solvent

[0027] About 50 mg of dry selective absorbent material A was added to a sealed bottle containing 10 ml of solvent. Allow selective absorption material A to fully absorb by standing at room temperature for 24 hours. The selective absorbent material A, which has fully absorbed the solvent, is separated from the sealed bottle, the surface absorbed solvent is sucked off with filter paper, and it is weighed immediately. The absorption capacity of selective absorbent material A in a single solvent is calculated by the following equation:

[0028]

[0029] Among them, m 干 Indicates the mass of dry selective absorbent material A; m 吸 Indicates the mass of the selective absorbing material A after fully absorbing the solvent.

[0030] The absorption capacity of selective absorbent material A in different solvents is shown in Table 1.

[0031] Table 1 The absorption capacity of sele...

Embodiment 3

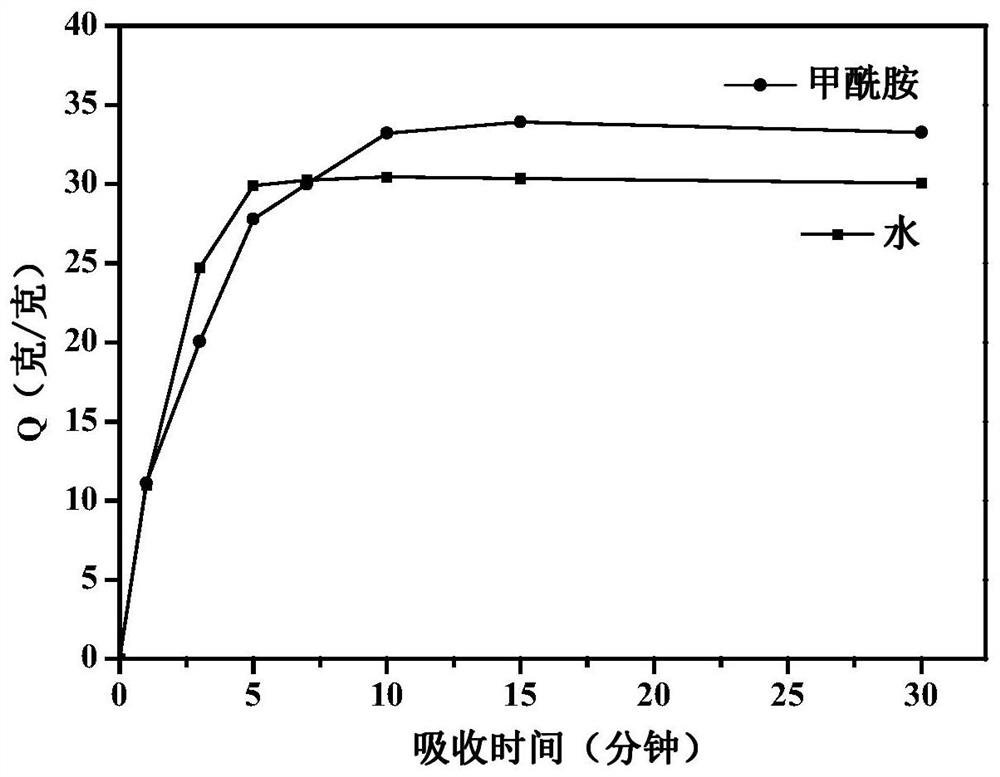

[0034] Example 3: Absorption Rate Test of Selective Absorbent Material A in Water and Formamide

[0035] In the present embodiment, the absorption capacity Q of selective absorbent material A to water and formamide, i.e. the absorption rate, is measured at different times; see figure 1 . figure 1 The results show that the selective absorbent material A can reach a fully absorbed state in water and formamide in only 5 minutes and 15 minutes. This indicates that the as-prepared selective absorbent material A has the ability to rapidly absorb solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com