Electron energy loss spectroscopy analysis method for characterization of fine structure of transition metal oxide

A technology of electron energy loss and transition metals, applied in material analysis using radiation diffraction, material analysis using radiation, etc., can solve problems such as low K-shell signal, restricted coordination structure, complex electronic structure of L-shell, etc. , to achieve high spatial resolution, high sensitivity, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is used for the electron energy loss spectroscopy analysis method of commercial FeO microstructure characterization, and the specific process is as follows:

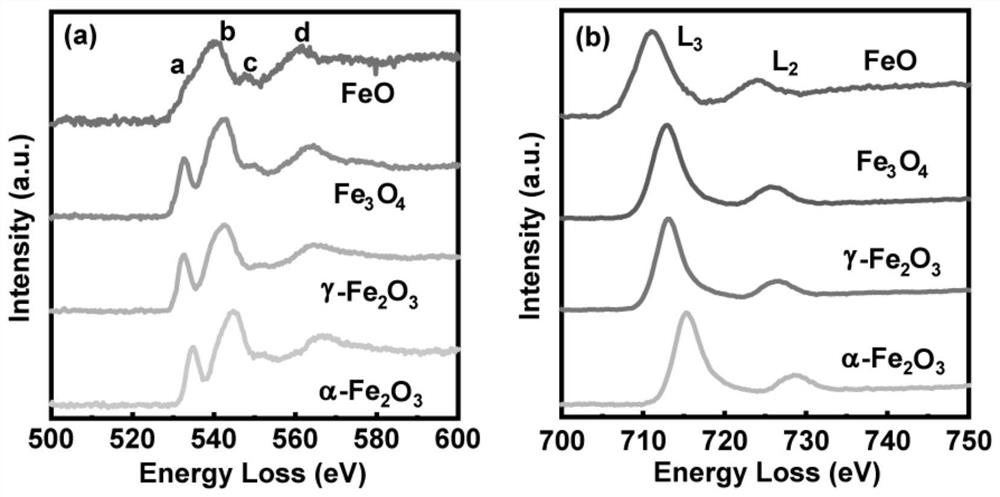

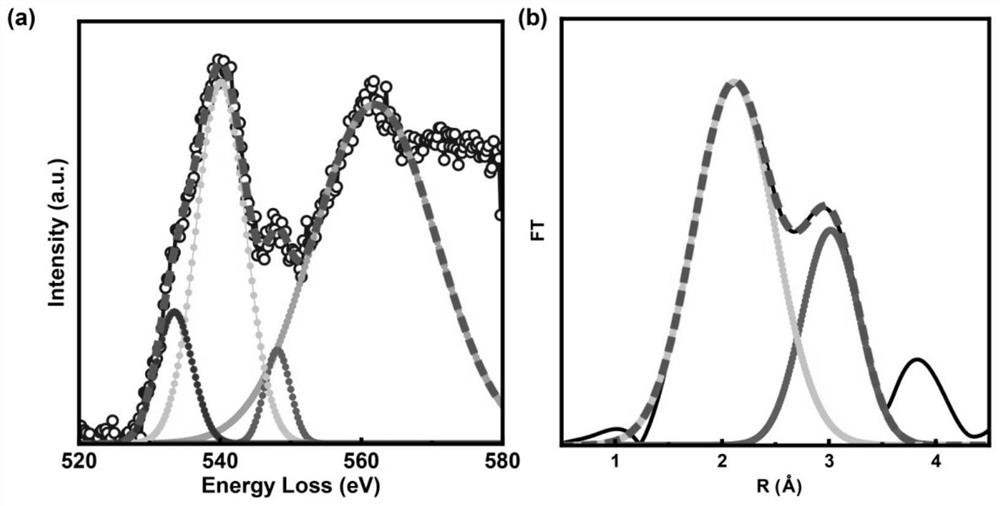

[0028] 1. Through the FEI Tecnai G equipped with a Gatan Imaging Filter (GIF) 965 spectrometer 2 The electron energy loss spectrum of the oxygen of commercial FeO was collected in the F20 TEM (see figure 1). Then Gaussian fitting was performed on the four peaks in FeO (approximately in the range of 530eV-580eV) by DigitalMicrograph software (see figure 2 ). The valence state of Fe can be calculated as +2.00 through the peak intensity ratio of the front peak (530-540eV) and the highest peak (540-550eV).

[0029] 2. Obtain the oxygen atom coordination structure through the extended fine structure of the electron energy loss spectrum of FeO: it is necessary to extract the oscillation signal in the extended fine structure of the electron energy loss spectrum of oxygen, and then perform signal denoi...

Embodiment 2

[0033] This embodiment is used for Fe 3 o 4 Electron energy loss spectroscopy analysis method for nanorod microstructure characterization, the specific process is as follows:

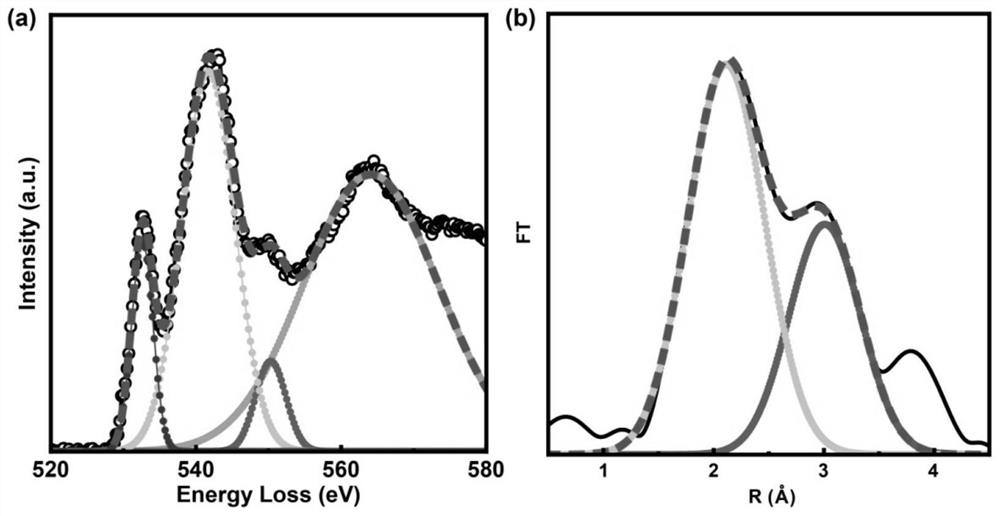

[0034] 1. Through the FEI Tecnai G equipped with a Gatan Imaging Filter (GIF) 965 spectrometer 2 Fe was collected in the F20 transmission electron microscope 3 o 4 The electron energy loss spectrum of the oxygen of the nanorods (see figure 1 ). Then by DigitalMicrograph software for Fe 3 o 4 The four peaks in the nanorods (approximately in the range of 530eV to 580eV) were Gaussian fitted (see image 3 ). The average valence state of Fe can be calculated by the peak intensity ratio of the front peak (530-540eV) and the highest peak (540-550eV) to be +2.69.

[0035] Second, through Fe 3 o 4 The oxygen electron energy loss spectrum extended fine structure of nanorods is obtained to obtain the oxygen atom coordination structure: it is necessary to extract the oscillation signal in the oxygen ele...

Embodiment 3

[0039] This embodiment is used for γ-Fe 2 o 3 Electron energy loss spectroscopy analysis method for nanorod microstructure characterization, the specific process is as follows:

[0040] 1. Through the FEI Tecnai G equipped with a Gatan Imaging Filter (GIF) 965 spectrometer 2 γ-Fe was collected in F20 transmission electron microscope 2 o 3 The electron energy loss spectrum of the oxygen of the nanorods (see figure 1 ). Then through DigitalMicrograph software for γ-Fe 2 o 3 The four peaks in the nanorods (approximately in the range of 530eV to 580eV) were Gaussian fitted (see Figure 4 ). The valence state of Fe can be calculated as +3.04 through the peak intensity ratio of the front peak (530-540eV) and the highest peak (540-550eV).

[0041] 2. Through γ-Fe 2 o 3 The oxygen electron energy loss spectrum extended fine structure of nanorods is obtained to obtain the oxygen atom coordination structure: it is necessary to extract the oscillation signal in the oxygen elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com