Solid dielectric thin film capacitor with low leakage conductance and high voltage resistance and preparation method thereof

A film capacitor and dielectric technology, which is applied in the field of low leakage conductance and high withstand voltage solid dielectric film capacitors and their preparation, can solve the problems of difficult and complicated processes, and achieve high energy storage density, simple preparation process and short time period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

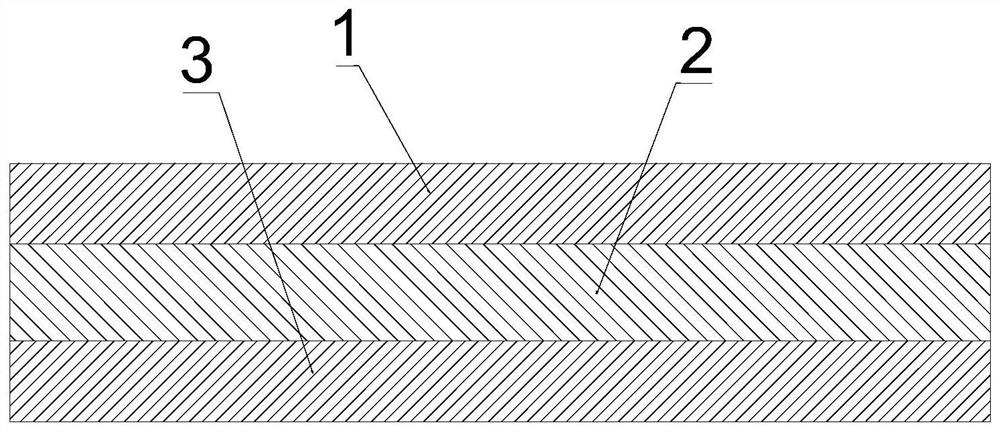

[0032] Such as figure 2 As shown, the present invention discloses a low-leakage conduction and high-voltage-resistant solid-state dielectric film capacitor, which includes a casing and a capacitor unit packaged in the casing, and the capacitor unit includes an upper electrode and an oxide dielectric arranged from top to bottom A film and a substrate, the surface of the oxide dielectric film is a layer of crystallized oxide. The oxide dielectric film is an aluminum oxide compound with a thickness of 210nm and uniform texture. The thickness of the crystallized oxide on the surface of the oxide dielectric thin film is 5nm.

[0033] The upper electrode is a metal electrode with a thickness of 150nm.

[0034] The upper electrode is deposited on the oxide dielectric film.

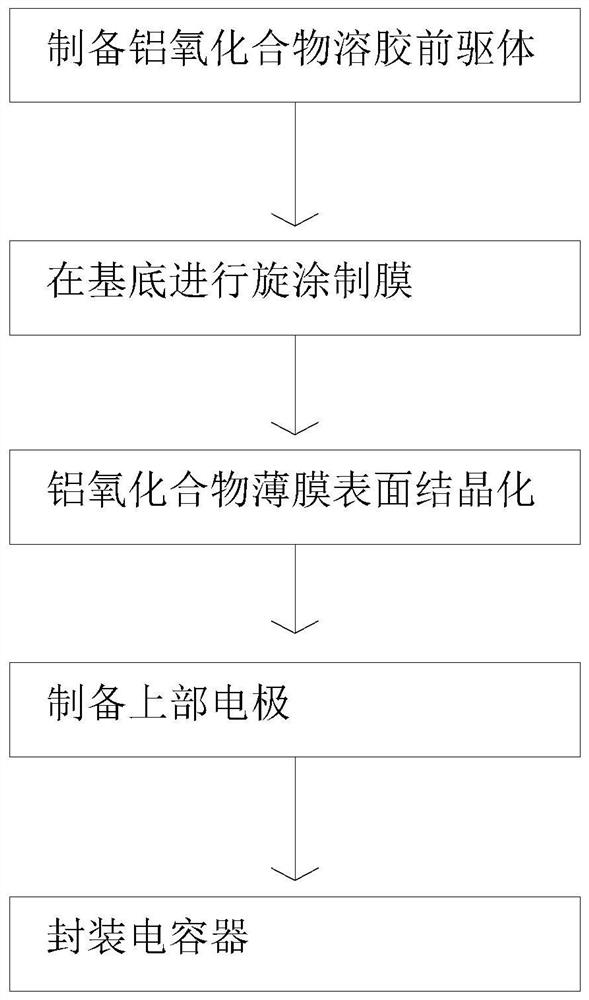

[0035] Such as figure 1 As shown, a method for preparing a low-leakage conduction high-voltage-resistant solid-state dielectric film capacitor specifically includes the following steps:

[0036] (1) Prepara...

Embodiment 2

[0047] In this example, the dielectric oxide was changed to a 300nm aluminum oxide dielectric film, and the upper electrode was an aluminum electrode.

[0048] Grind 0.02mol of aluminum isopropoxide first, then add 50mL of ethylene glycol ether to sonicate for 10min, stir at 70°C for 30 minutes; add 0.03mol of acetylacetone, stir at 60°C for 30 minutes; add 10mL of acetic acid, and stir at 60°C for 30 minutes. After the reaction was completed, it was gradually cooled to room temperature, and finally filtered to obtain 60 mL of a clear aluminum oxide precursor. Place the Pt with a clean and dry surface on the silicon wafer evenly, place it on a homogenizer, then drop the sol precursor on the surface of the substrate, and evenly coat the sol on the surface of the substrate at a speed of 3000 rpm. Then the sample was placed in a tube furnace for drying and heat treatment. The pre-drying process conditions were 150°C for 2 minutes in air, 350°C for 2 minutes, and 450°C for 2 minut...

Embodiment 3

[0051] In this example, the rigid capacitor is changed into a flexible capacitor, and the upper electrode is prepared as a gold electrode, and the substrate is made of a flexible aluminum foil.

[0052] Grind 0.02mol of aluminum isopropoxide first, then add 60mL of ethylene glycol ether to ultrasonic for 10 minutes, stir at 70°C for 30 minutes; add 0.03mol of acetylacetone, stir at 60°C for 30 minutes; add 10mL of acetic acid, and stir at 60°C for 30 minutes. After the reaction was completed, it was gradually cooled to room temperature, and finally filtered to obtain 60 mL of a clear aluminum oxide precursor. Place the aluminum foil with a clean and dry surface on the silicon wafer, place it on a homogenizer, then drop the sol precursor on the surface of the substrate, and evenly coat the sol on the surface of the substrate at a speed of 3000 rpm. Then put the sample in a tube furnace for drying and heat treatment. The pre-drying process conditions are 150°C for 2 minutes in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com