Solar concentrator with reflection resistance and high transmittance and preparation method thereof

A solar concentrator, high transmittance technology, applied in solar collectors, solar thermal energy, solar thermal power generation, etc., can solve the problem of luminescent solar concentrators and anti-reflection films with less research, complex cost and testing methods, etc. To achieve the effect of clear experimental results, simple preparation method and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Weigh 4mmol (740mg) of the ligand 2mCND into the reactor, add 20ml of absolute ethanol, sonicate, then add 40ml of 0.1mol / L NaOH ethanol solution into the reactor, and continue to sonicate for 30min until most Dissolves and becomes almost a clear liquid.

[0056] (2) After heating the solution oil bath obtained above for half an hour, add 10ml of 0.1mol / L EuCl 3 Ethanol solution, a white precipitate appeared after stirring for 12 hours.

[0057] (3) Ultrasonicate, centrifuge, wash the solution containing the white precipitate obtained above, and dry it in an oven (70°C) to obtain a luminescent rare earth complex (Eu(2mCND) 4 Na).

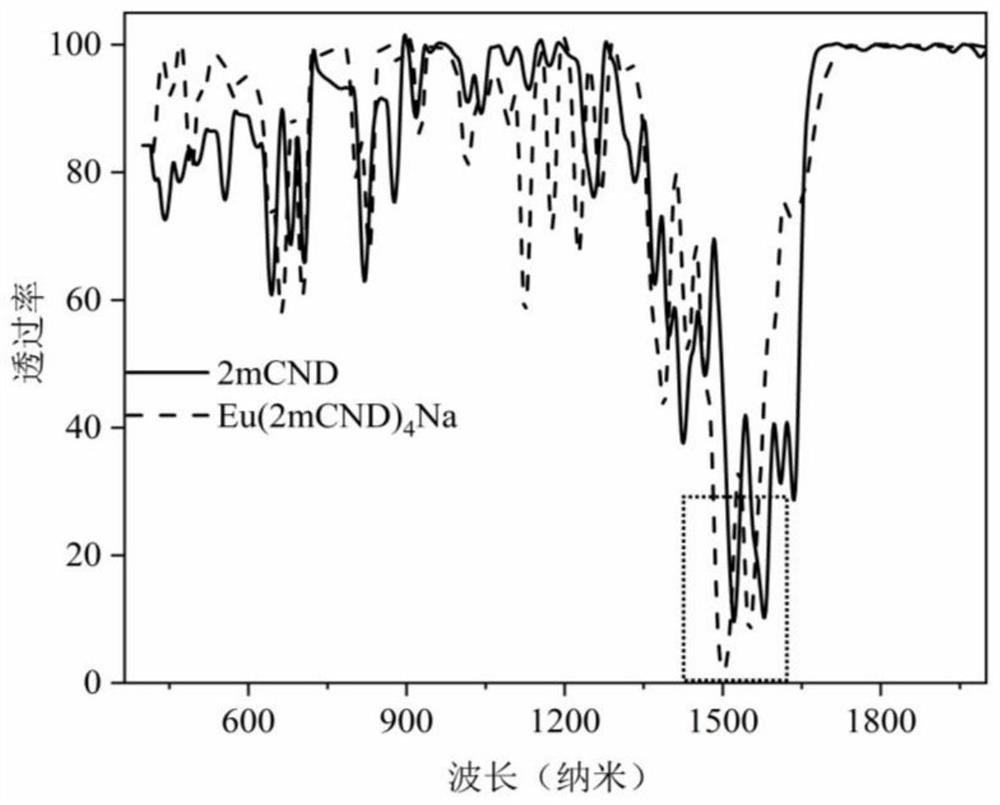

[0058] figure 1 Infrared absorption spectrum of rare earth complex powder. It can be seen from the figure that one rare earth ion is coordinated with four ligands, which proves the structure of the rare earth complex.

Embodiment 2

[0060] (1) get the rare earth complex Eu(2mCND) that embodiment 1 makes 4 Na powder 25mg was dissolved in 10mL DMF to obtain Eu(2mCND) 4 Na / DMF solution.

[0061] (2) Put 1 g of polymethyl methacrylate powder into a reactor, add 10 mL of DMF, and heat in an oil bath at 70° C. for 30 min until the polymethyl methacrylate is completely dissolved to obtain a PMMA / DMF solution.

[0062] (3) Take Eu(2mCND) in step (1) 4 Take 1 mL of Na / DMF solution, take 1 mL of PMMA / DMF solution obtained in step (2), and mix the two evenly. The mixed solution was also bright red under UV light.

[0063] The resulting 2mL Eu(2mCND) 4 The Na / PMMA solution is evenly coated on the acrylic glass of 12.5 square centimeters, and heated at 90°C for 90 minutes until the solution on the acrylic solidifies into a transparent film with a thickness of 774nm. The effect of the optical waveguide can be seen from the side of the film under the action of the fluorescent lamp , showing red light.

[0064] F...

Embodiment 3

[0066] Step (2) (3) is identical with step (2) (3) in embodiment 2, and step (1) is different from step (1) in embodiment 2 in that the rare earth complex Eu ( 2mCND) 4 Na powder, other conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com