Uniform heat-conducting non-stick pan coating and preparation method thereof

A non-stick pan and coating technology, applied in coatings, polyester coatings, etc., can solve the problem of limited influence of coating material structural strength and thermal conductivity, shortening the service life of non-stick pan coatings, and limited improvement in coating performance. and other problems, to achieve the effect of increasing steric hindrance effect, improving mechanical properties and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

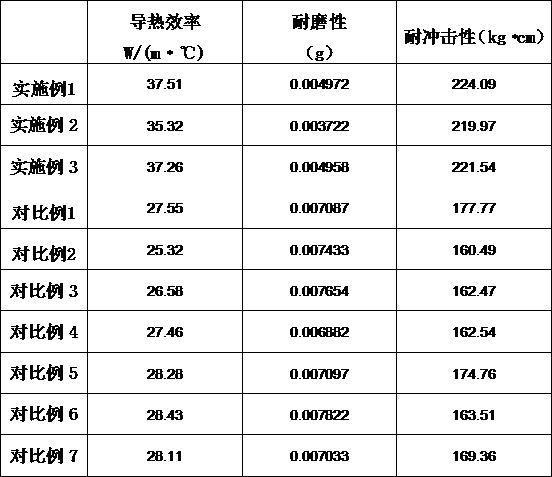

Examples

Embodiment 1

[0023] A non-stick pan coating with uniform heat conduction, the coating is composed of the following raw materials in parts by mass: 49 parts of silicon carbide, 30 parts of alumina ceramic powder, 100 parts of aluminum nitride, 20 parts of modified nano-silicon nitride, 150 parts of saturated polyester resin, 100 parts of silicone resin, 1 part of hydrogenated castor oil; the fineness of the silicon carbide is 50nm; in parts by mass, the modified nano-silicon nitride consists of 1 part of nano-silicon nitride powder, Prepared from 0.1 part of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane and 5 parts of stearic acid; the saturated polyester resin is cp3612;

[0024] The preparation method of the non-stick pan coating with uniform heat conduction described in this embodiment comprises the following steps:

[0025] (1) Put the nano-silicon nitride powder in the heating dish, heat it to 150°C, lower the temperature to 80°C, place the heating dish in an environment with an oxygen...

Embodiment 2

[0030] A non-stick pan coating with uniform heat conduction, the coating is composed of the following raw materials in parts by mass: 55 parts of silicon carbide, 50 parts of alumina ceramic powder, 130 parts of aluminum nitride, 30 parts of modified nano-silicon nitride, 180 parts of saturated polyester resin, 130 parts of silicone resin, 3 parts of hydrogenated castor oil; the fineness of the silicon carbide is 60nm; in parts by mass, the modified nano-silicon nitride consists of 3 parts of nano-silicon nitride powder, Prepared from 0.25 parts of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane and 8 parts of stearic acid; the saturated polyester resin is cp3612;

[0031] The preparation method of the non-stick pan coating with uniform heat conduction described in this embodiment comprises the following steps:

[0032](1) Put the nano-silicon nitride powder in a heating dish, heat it to 180°C, lower the temperature to 90°C, place the heating dish in an environment with an oxyge...

Embodiment 3

[0037] A non-stick pan coating with uniform heat conduction, the coating is composed of the following raw materials in parts by mass: 51 parts of silicon carbide, 34 parts of alumina ceramic powder, 107 parts of aluminum nitride, 26 parts of modified nano-silicon nitride, 159 parts of saturated polyester resin, 107 parts of silicone resin, 3 parts of hydrogenated castor oil; the fineness of the silicon carbide is 60nm; in parts by mass, the modified nano-silicon nitride consists of 1 part of nano-silicon nitride powder, Prepared from 0.25 parts of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane and 8 parts of stearic acid; the saturated polyester resin is cp3612;

[0038] The preparation method of the non-stick pan coating with uniform heat conduction described in this embodiment comprises the following steps:

[0039] (1) Put the nano-silicon nitride powder in the heating dish, heat it to 180°C, lower the temperature to 80°C, place the heating dish in an environment with an oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com