Negative plate, preparation method thereof and lithium ion battery

A lithium-ion battery and negative electrode technology, which is applied in negative electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as complex process steps, expensive equipment investment, and impact on battery performance, achieve uniform porosity, improve transmission capacity, The effect of reducing the possibility of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

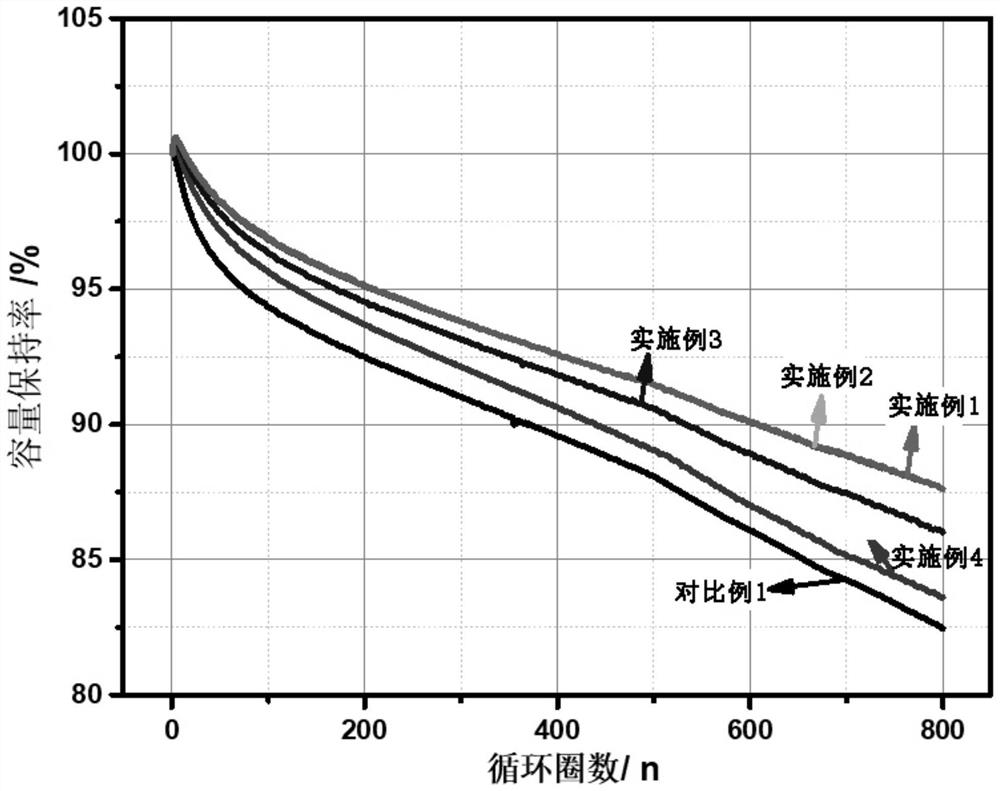

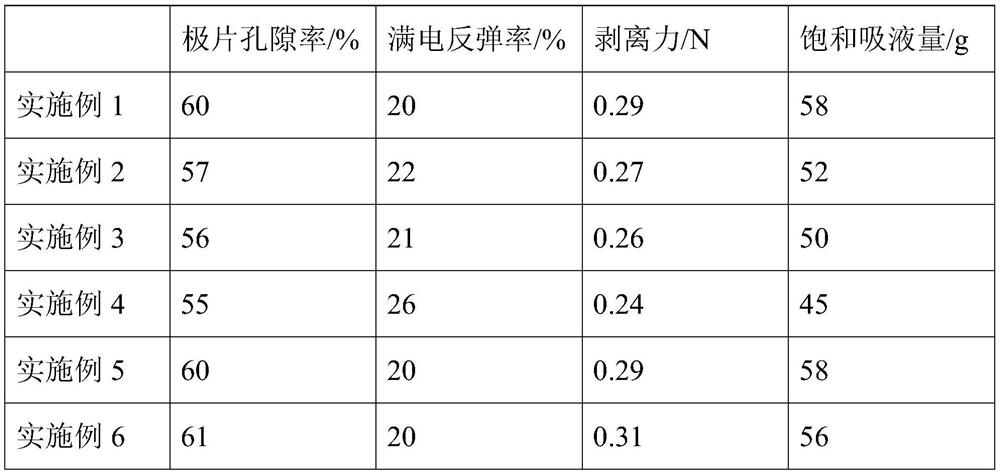

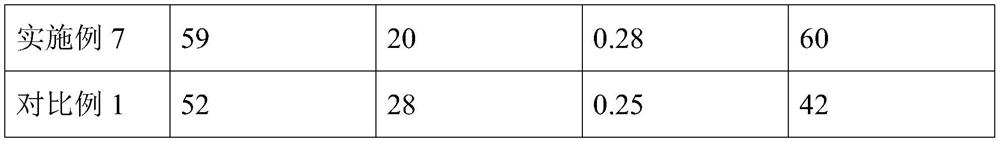

Embodiment 1

[0058] The present embodiment prepares the negative plate according to the following method:

[0059] (1) Mix the binder styrene-butadiene rubber (SBR) and water in a Ross mixer evenly to obtain glue. Weigh a certain amount of negative electrode active components (graphite negative electrode material), dispersant sodium carboxymethyl cellulose (CMC), conductive agent (conductive carbon black), etc., and add them to the glue, and mix them uniformly to obtain a stable negative electrode slurry, in which each The material mass ratio is: negative electrode active component: binder: dispersant: conductive agent is 32:4:1:4, and the solid content of the negative electrode slurry is 51.2%.

[0060] (2) Apply the slurry described in step (1) evenly on the copper foil to ensure that the density on one side of the negative electrode is 90mg / mm 2 , the density of both sides is 180mg / mm 2 , to get the semi-finished negative plate.

[0061] (3) Carry out two cold pressings on the negati...

Embodiment 2

[0071] The difference between this embodiment and embodiment 1 is that in the method for preparing the negative electrode sheet, the value of X in step (3) is 50%, and T is calculated with this 1 value. Other raw materials and operating parameter are identical with embodiment 1.

[0072] The method for preparing the positive electrode sheet and the battery cell of the lithium-ion battery in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0074] The difference between this embodiment and embodiment 1 is that in the method for preparing the negative electrode sheet, the value of X in step (3) is 30%, and T is calculated with this 1 value. Other raw materials and operating parameter are identical with embodiment 1.

[0075] The method for preparing the positive electrode sheet and the battery cell of the lithium-ion battery in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com