Preparation method and product of prolamin microcapsule

A gliadin and microcapsule technology, applied in the field of preparation of gliadin microcapsules, can solve problems such as unfavorable large-scale production, difficulty in meeting production requirements of synthetic polymers, and achieve the effects of good dispersibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Dissolving zein powder in an ethanol / water mixture (v / v, mL:mL, 7 / 3) to prepare a 20% zein ethanol / water solution;

[0040] (2) Get 0.2g of silicon dioxide and disperse it in 20mL of caprylic / capric triglyceride as the oil phase;

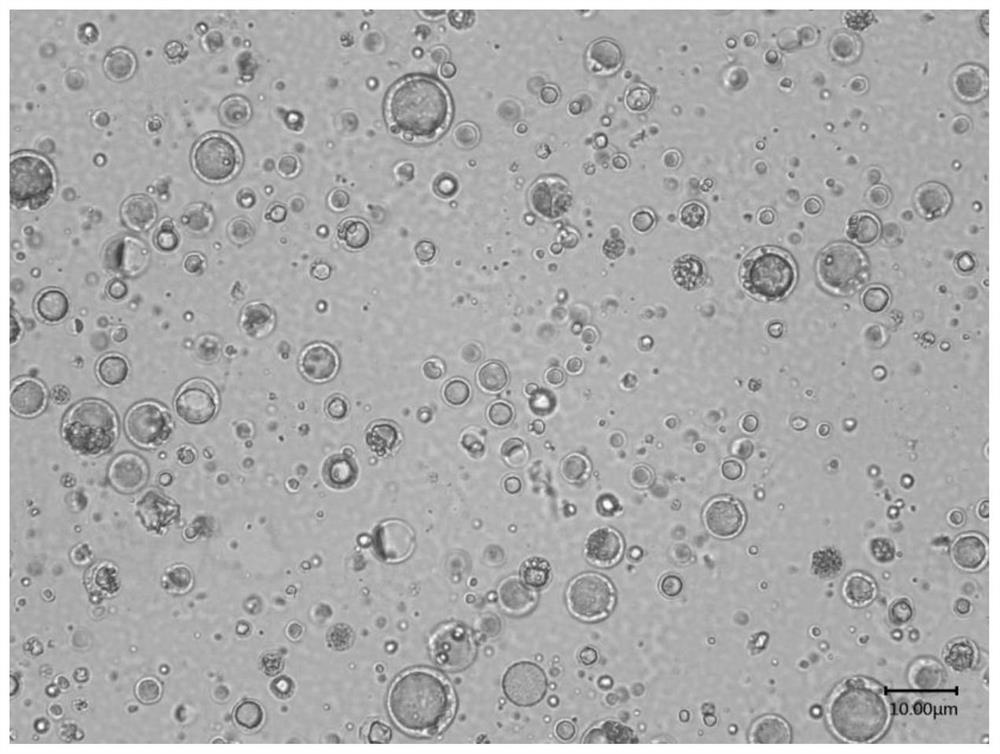

[0041] (3) Add 4 mL of prefabricated zein ethanol / water solution to 20 mL of oil phase, and homogeneously emulsify to obtain multiple emulsions, see figure 1 ;

[0042] (4) Remove the ethanol and part of the water in the previously prepared emulsion by heating with rotary evaporation at 45°C, so that the zein protein precipitates and solidifies, and the obtained precipitate is washed with n-hexane for more than three times and vacuum-dried at 50°C for 12 hours to obtain the alcohol Soluble Protein Microcapsules.

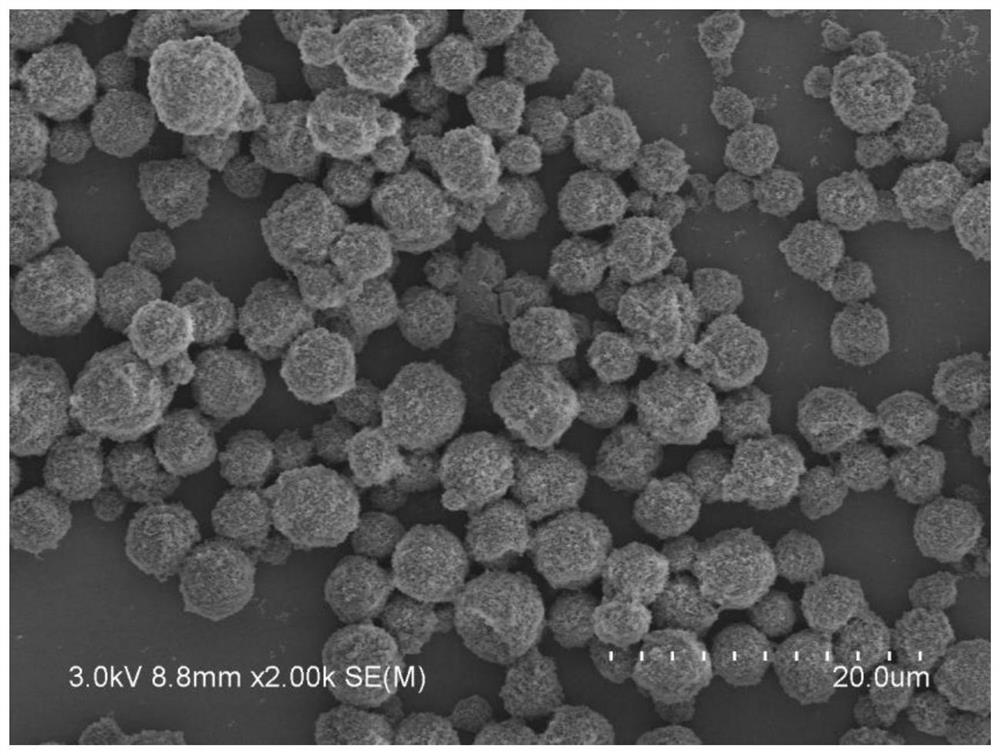

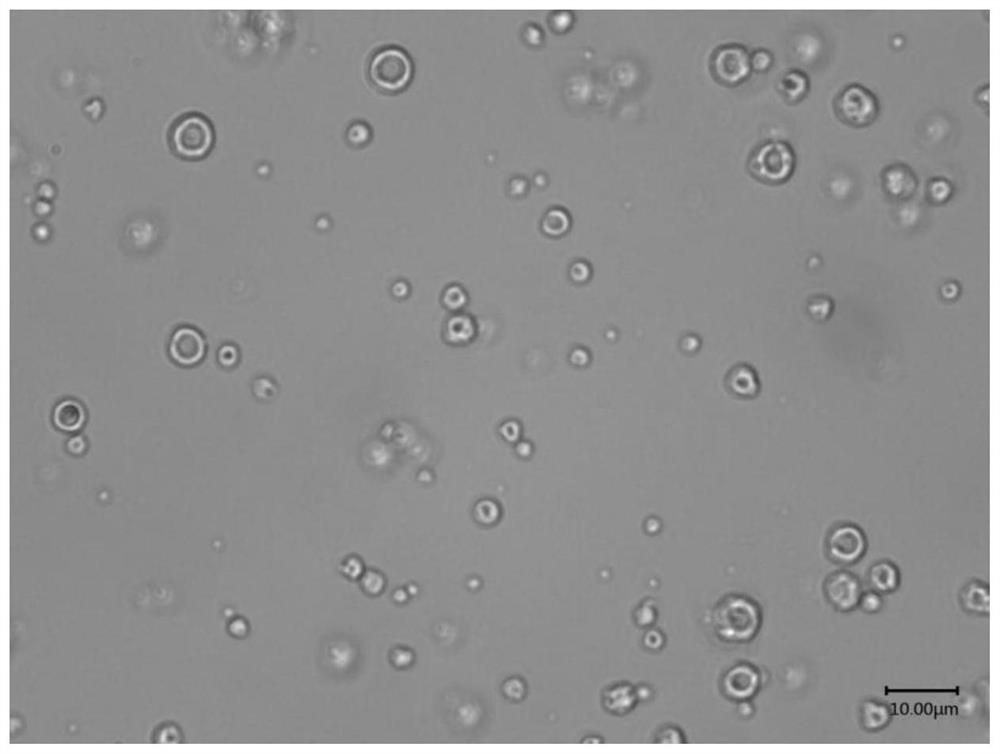

[0043] (5) The test results show that the particle size of the microcapsules is about 10-30 μm, see figure 2 and image 3 .

Embodiment 2

[0045] (1) Dissolving zein powder in an ethanol / water mixture (v / v, mL:mL, 7 / 3) to prepare a 20% zein ethanol / water solution;

[0046] (2) Take 0.1g of silicon dioxide and disperse it in 20mL of caprylic / capric triglyceride as the oil phase;

[0047] (3) Add 4 mL of prefabricated zein ethanol / water solution into 20 mL of oil phase, and homogeneously emulsify to obtain a multiple emulsion;

[0048] (4) Remove the ethanol and part of the water in the previously prepared emulsion by heating with rotary evaporation at 45°C, so that the zein protein precipitates and solidifies, and the obtained precipitate is washed with n-hexane for more than three times and vacuum-dried at 50°C for 12 hours to obtain the alcohol Soluble Protein Microcapsules.

[0049] (5) The test results show that the particle size of the microcapsules is about 5-30 μm, see Figure 4 .

Embodiment 3

[0051] (1) Dissolving zein powder in an ethanol / water mixture (v / v, mL:mL, 7 / 3) to prepare a 20% zein ethanol / water solution;

[0052] (2) Get 0.4g of silicon dioxide and disperse it in 20mL of caprylic / capric triglyceride as the oil phase;

[0053](3) Add 4 mL of prefabricated zein ethanol / water solution into 20 mL of oil phase, and homogeneously emulsify to obtain a multiple emulsion;

[0054] (4) Remove the ethanol and part of the water in the previously prepared emulsion by heating with rotary evaporation at 45°C, so that the zein protein precipitates and solidifies, and the obtained precipitate is washed with n-hexane for more than three times and vacuum-dried at 50°C for 12 hours to obtain the alcohol Soluble Protein Microcapsules.

[0055] (5) The test results show that the particle size of the microcapsules is about 10-20 μm, see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com