Core-shell heterostructure magnetic nanowire as well as preparation method and application thereof

A heterostructure, magnetic nanotechnology, applied in the field of nanowire materials, can solve the problems of poor microwave absorption performance, strict equipment requirements, high temperature energy consumption, etc. The effect of oxidation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

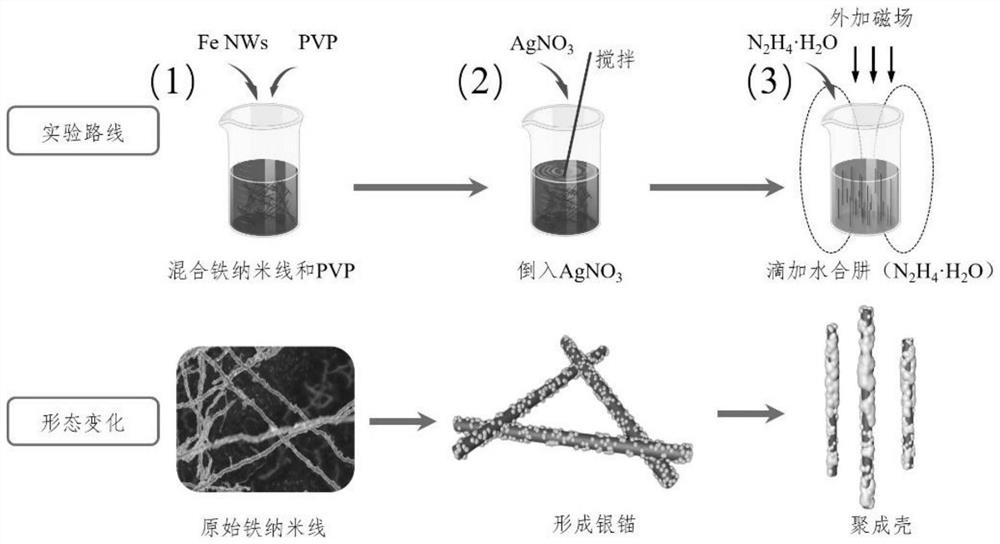

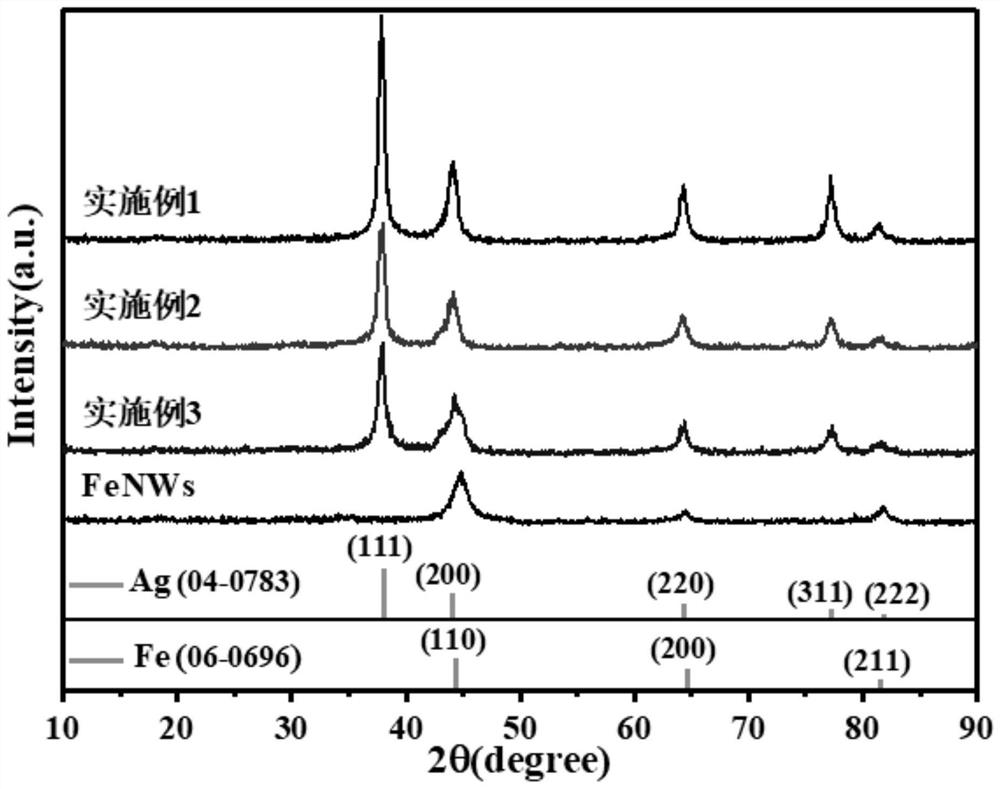

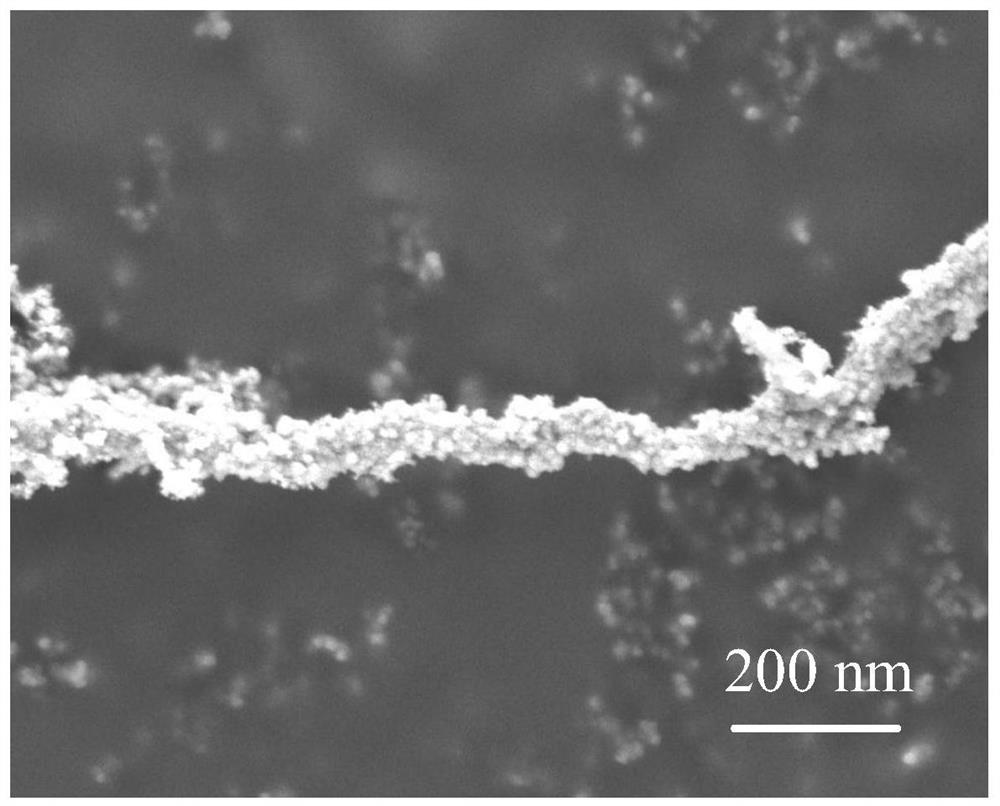

[0034] Preparation of core-shell heterostructure magnetic nanowires, the specific preparation process is as follows figure 1 shown, including the following steps:

[0035] (1) Add ferromagnetic nanowires (FeNWs) into deionized water to prepare 100ml of ferromagnetic nanowire aqueous solution with a concentration of 20mmol / L, ultrasonically treat for 10min to disperse ferromagnetic nanowires evenly, then add 0.3g dispersant polyethylene Pyrrolidone (PVP) prevents agglomeration;

[0036] (2) Configure 100ml of silver nitrate solution with a concentration of 20mmol / L, add an equal amount of silver nitrate solution and ferromagnetic nanowire aqueous solution, stir for 10min to make it evenly mixed;

[0037] (3) Add a magnetic field device above the reaction tank to keep it parallel to the top of the reaction vessel, then add 100ml of hydrazine hydrate with a concentration of 2mol / L dropwise and let it stand for 30min to react.

[0038] (4) After being centrifuged, washed with ab...

Embodiment 2

[0041] The preparation of core-shell heterostructure magnetic nanowires specifically includes the following steps:

[0042](1) Add ferromagnetic nanowires (FeNWs) into deionized water to prepare 100ml of ferromagnetic nanowire aqueous solution with a concentration of 21mmol / L, ultrasonically treat for 10min to disperse ferromagnetic nanowires evenly, then add dispersant 0.15g glycerol, 0.15g ethylenediamine tetraacetate, 0.2g sodium nitrilotriacetate to prevent agglomeration;

[0043] (2) Configure 100ml of silver nitrate solution with a concentration of 23.1mmol / L, add an equal amount of silver nitrate solution and ferromagnetic nanowire aqueous solution, stir for 10min to make it evenly mixed;

[0044] (3) Add a magnetic field device above the reaction tank to keep it parallel to the top of the reaction vessel, then add 100ml of hydrazine sulfate with a concentration of 2.4mol / L dropwise and let it stand for 30min to react.

[0045] (4) After being centrifuged, washed with ...

Embodiment 3

[0048] The preparation of core-shell heterostructure magnetic nanowires specifically includes the following steps:

[0049] (1) Add ferromagnetic nanowires (FeNWs) into deionized water to prepare 100ml of ferromagnetic nanowire aqueous solution with a concentration of 18mmol / L, ultrasonically treat for 10min to disperse ferromagnetic nanowires evenly, then add dispersant 0.1g pyrophosphoric acid Sodium, 0.1g sodium ethylenediaminetetramethylene phosphate to prevent agglomeration;

[0050] (2) Configure 100ml of silver nitrate solution with a concentration of 5.4mmol / L, add an equal amount of silver nitrate solution and ferromagnetic nanowire aqueous solution, stir for 10min to make it evenly mixed;

[0051] (3) Add a magnetic field device above the reaction tank to keep it parallel to the top of the reaction vessel, then drop 100ml of formaldehyde with a concentration of 1.6mol / L and let it stand for 30min to react.

[0052] (4) After being centrifuged, washed with absolute e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com